Three-dimensional simulation test device for surface movement in underground coal mining and test method

A technology of underground mining and ground surface movement, which is applied in underground mining, optical devices, ground mining, etc., can solve problems such as the influence of manual excavation, difficult trial production success, difficult model test research, etc., and achieves high bending deformation resistance, Easy disassembly and splicing to ensure the effect of accuracy

Pending Publication Date: 2018-06-29

SHANDONG UNIV OF SCI & TECH

View PDF4 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] After searching, most of the existing simulation test devices for similar materials in coal mining are two-dimensional test benches (CN205642864U, CN204789567U) for simulating the movement of coal mine excavation roof and rock strata. limitations, and the simulation test is inevitably affected by manual excavation; some three-dimensional test devices are mostly box-type structures (CN204594982U,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

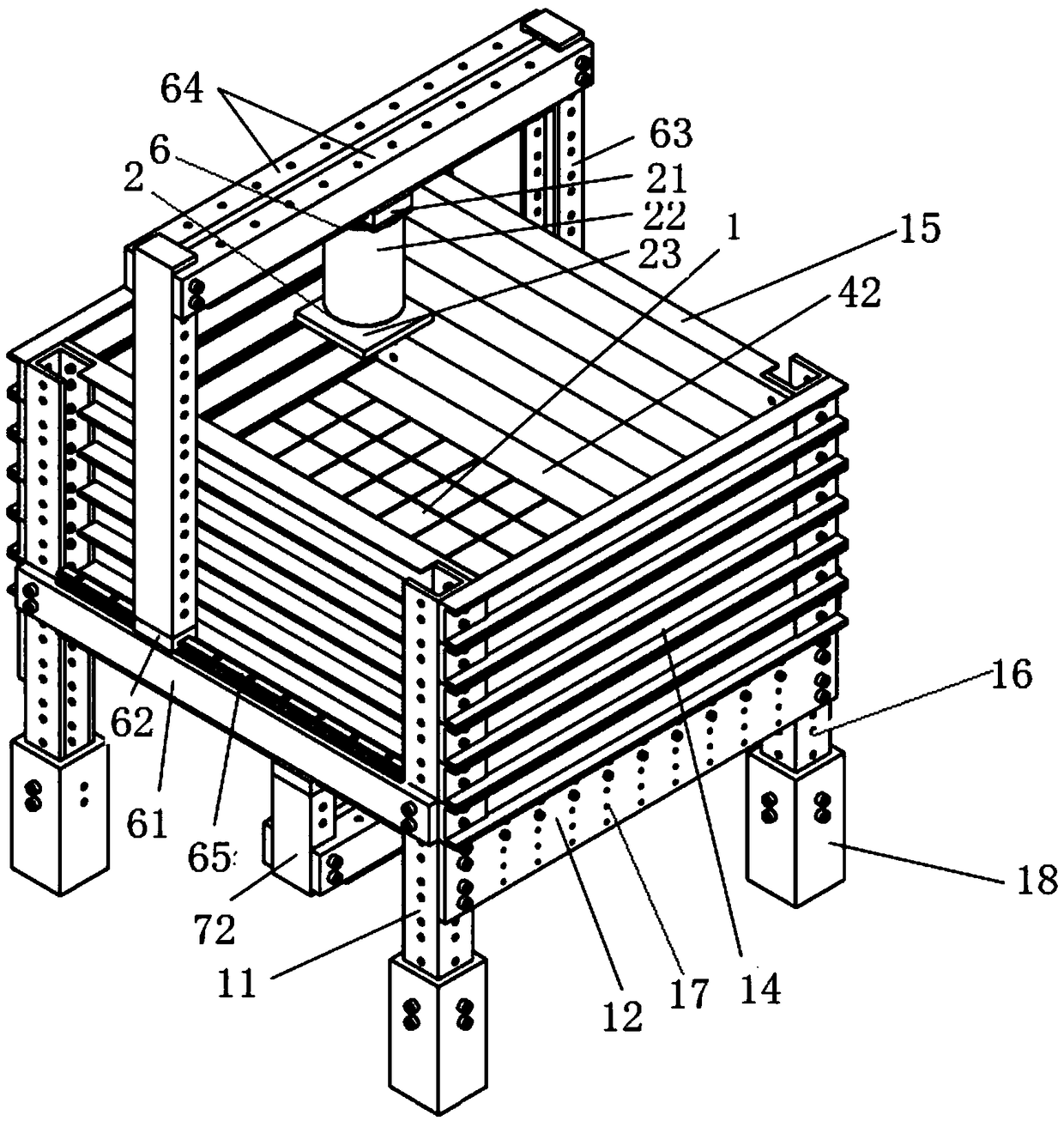

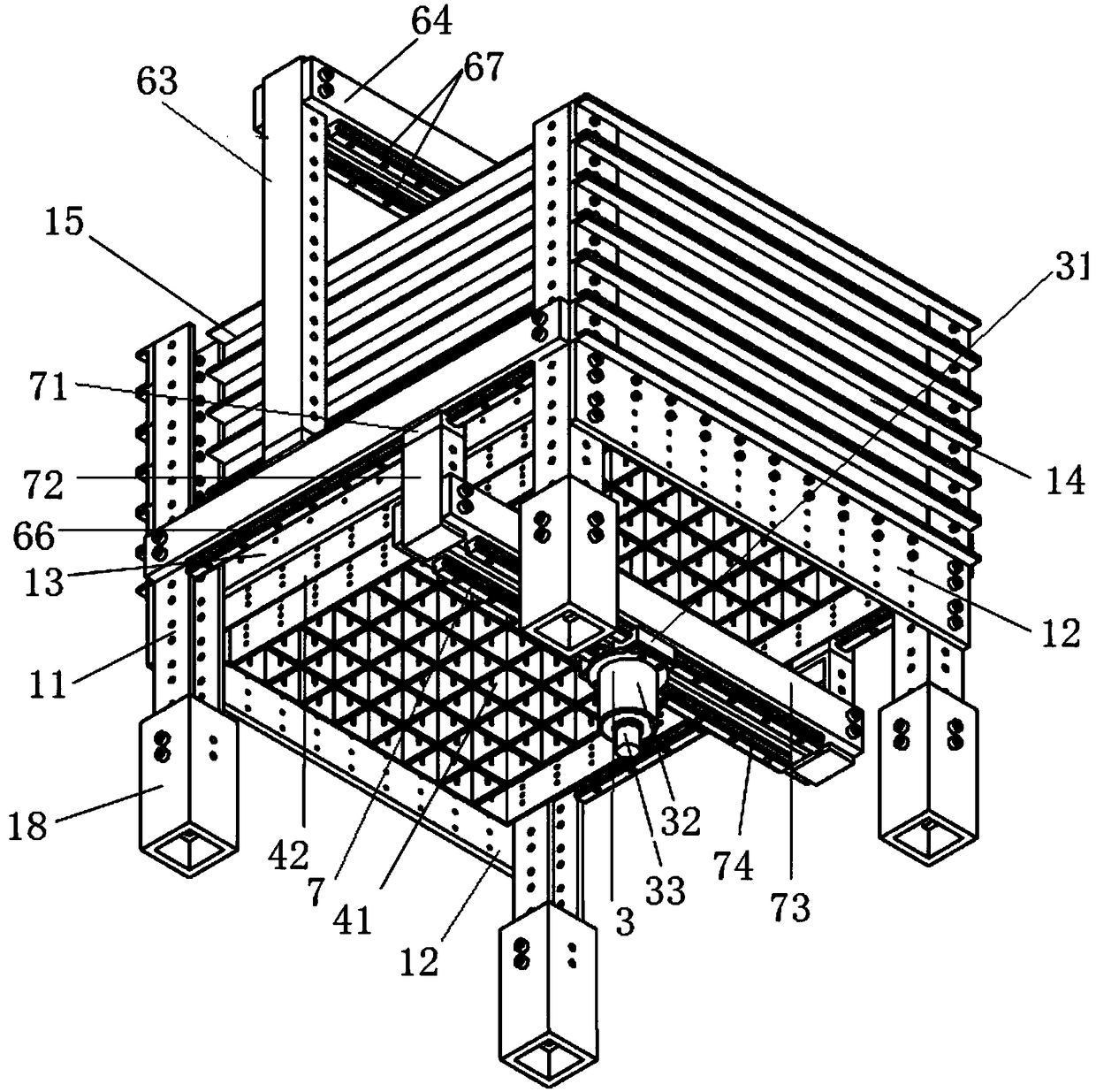

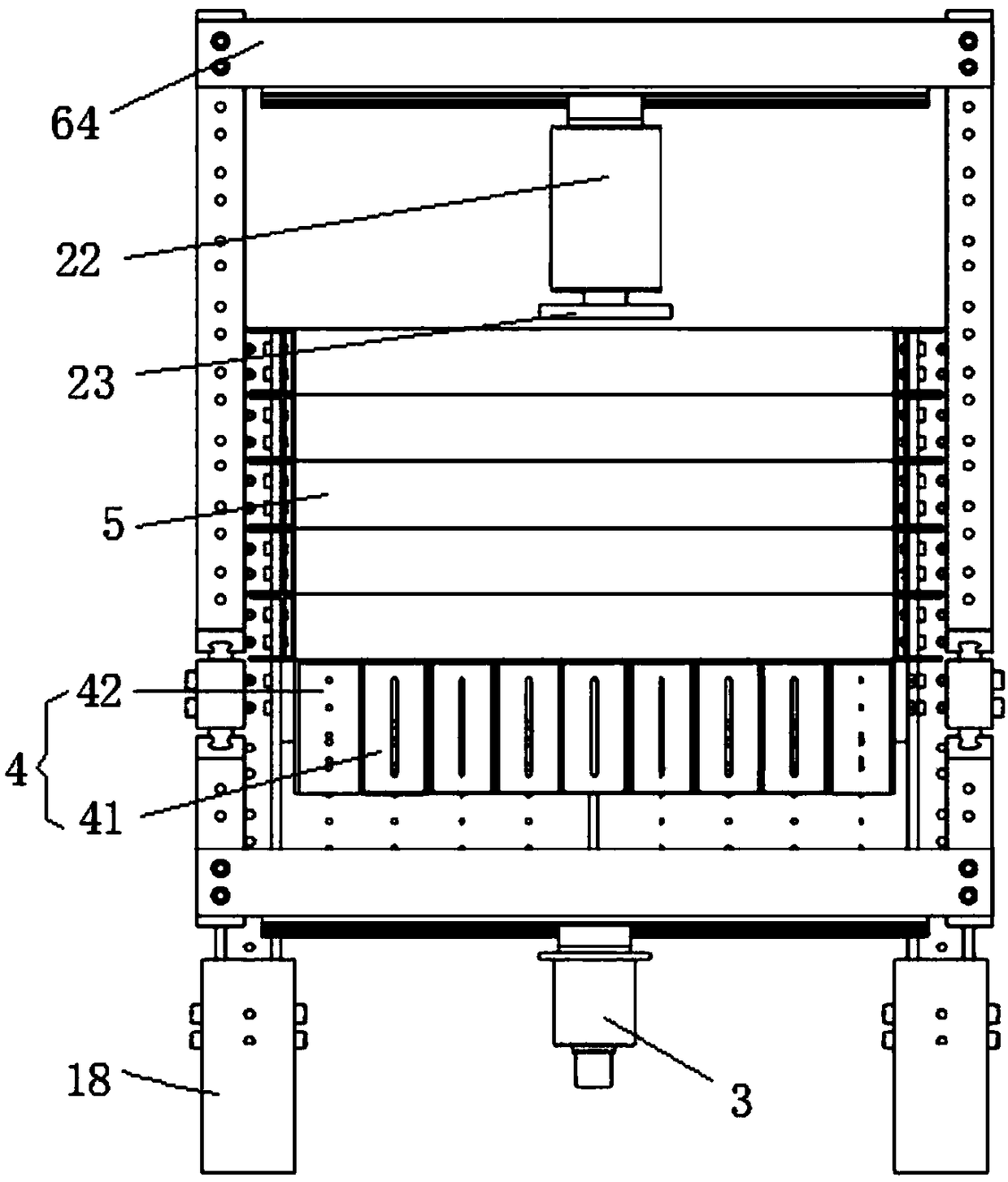

The invention discloses a three-dimensional simulation test device for surface movement in underground coal mining and a test method. The three-dimensional simulation test device comprises an outer frame, a pressurizing mechanism, a drawing mechanism and a coal-layer simulation part, wherein the coal-layer simulation part is arranged in the outer frame, and a coal-layer similar material also fillsthe upper surface of the coal-layer simulation part; the coal-layer simulation part comprises a plurality of coal mining blocks and a plurality of reserved coal pillar components; the pressurizing mechanism is arranged at the top part of the outer frame, and is connected with the outer frame by a pressurizing-position adjusting unit; the drawing mechanism is arranged at the bottom part of the outer frame, and is connected with the outer frame by a drawing-position adjusting unit. The three-dimensional simulation test device can be combined with a coal mining site to simulate irregular strip mining, and has the beneficial effects that the mining height is changeable, the mining speed is controllable, and pressurized pavement of similar materials is convenient.

Description

technical field [0001] The invention relates to the technical field of mine mining simulation tests, in particular to a three-dimensional simulation test device and test method for underground coal mining surface movement. Background technique [0002] With the continuous mining of coal resources in my country, the expansion of urban construction scale, and the increase of village relocation costs, the problem of coal mining has become an important factor restricting the sustainable development of coal mines. At present, many mines in the eastern part of my country are facing severe "three-down" coal pressure problems, and the amount of coal resources mined in mines is gradually decreasing. Strip mining is an effective method to solve coal pressure, that is, the area to be mined is divided into several strips reasonably, and the strips are mined and reserved in a planned order, and the reserved strips support the goaf Overlying rock mass in the area, thereby alleviating sur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/24G01B11/24

CPCG01B11/24G01N33/24G01B11/16E21C41/18

Inventor 赵同彬邢明录李志慧张丰雪王爱林蓝盛

Owner SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com