Variable pitch screw rotor forming device

A molding device and variable pitch technology are applied in the field of manufacturing equipment for variable-lead screw rotors, which can solve problems such as difficulty in realizing molding processing methods, and achieve the effects of batch processing, convenient disassembly and splicing, and guaranteeing processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

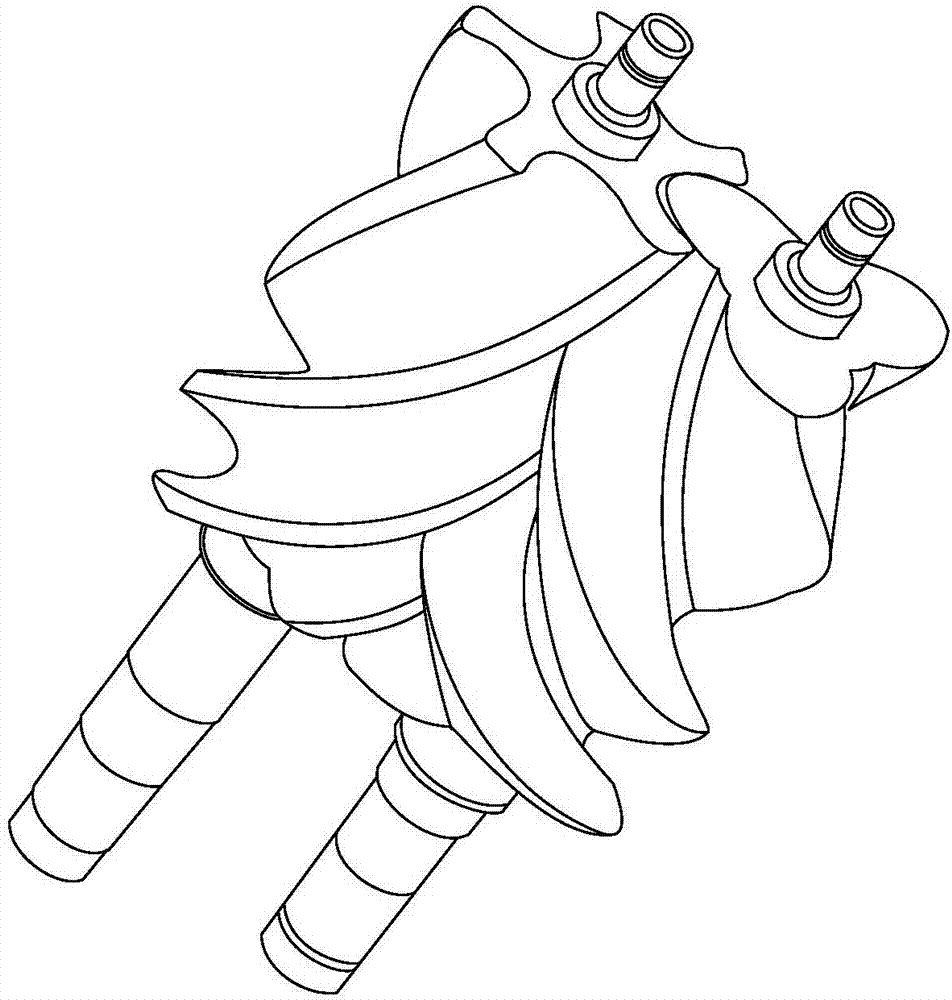

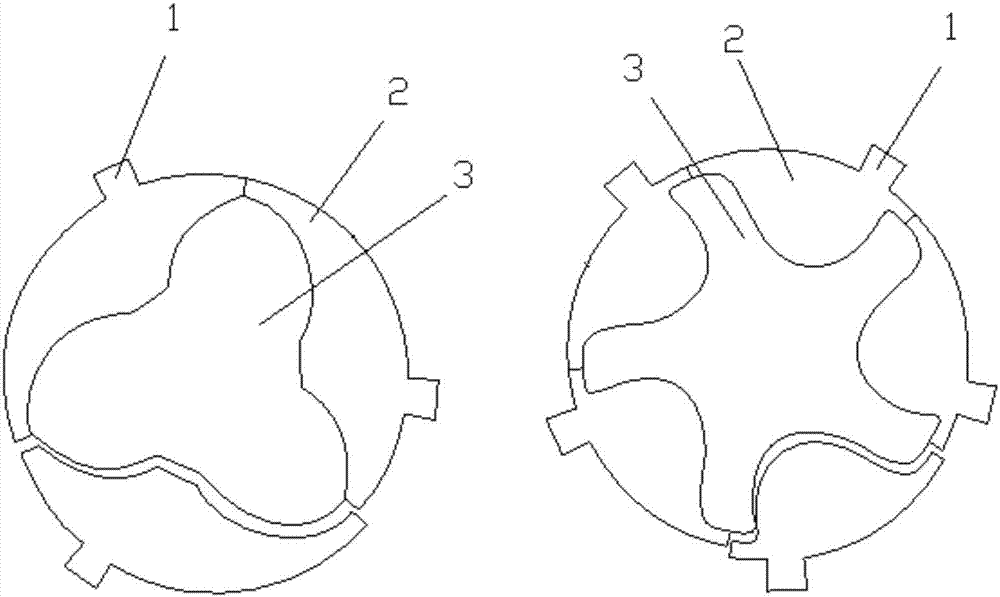

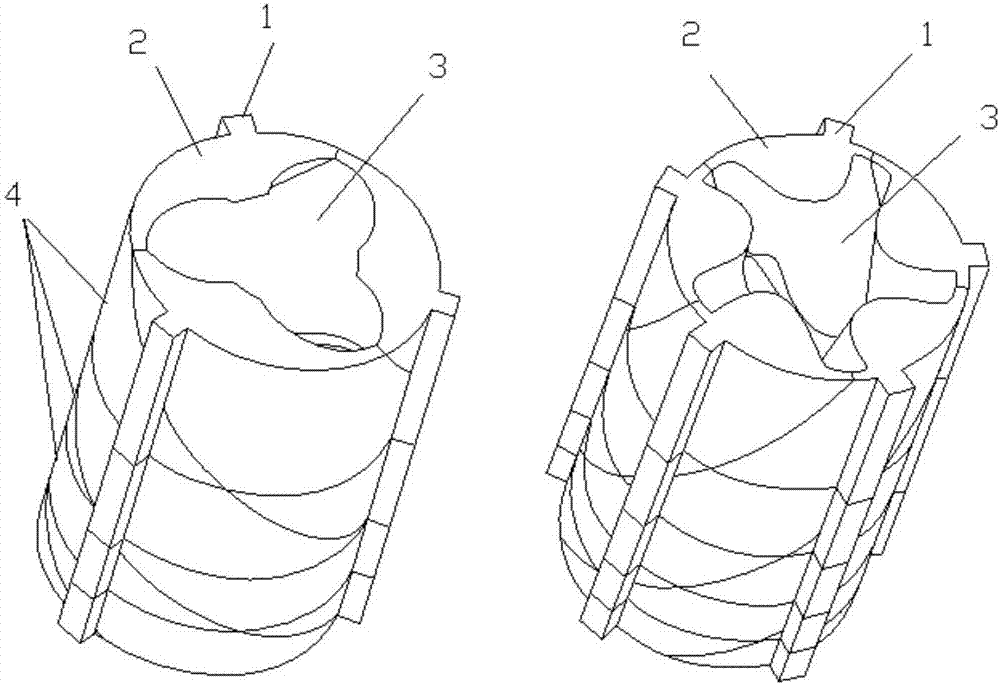

[0021] figure 1 It is a structural schematic diagram of the variable lead screw rotor of the present invention; figure 2 It is a sectional view of the screw forming die 7 of the present invention; image 3 It is the axonometric view of screw forming die 7 of the present invention; Figure 4 It is an explosion diagram of the present invention. The variable pitch screw rotor molding device of this embodiment includes a casing 9, a screw molding die 7 arranged in the casing 9 and having a screw cavity, and a tool for pressurizing the metal powder in the cavity. The push rod 5 and the guide sleeve 6 for guiding the push rod 5; the variable pitch screw rotor molding device of the present invention, when forming the screw, metal powder (using powder metallurgy) or molten metal (using die casting) It can be filled in the forming cavity 3 in the screw forming die 7, the inner end of the screw forming die 7 is limited and sealed by the tray 8, and the metal powder or molten metal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com