Turbine blade bent branch net type cooling structure

A technology for cooling structure and turbine blades, which is applied in the direction of blade support components, engine components, machines/engines, etc., which can solve the problems of small heat transfer area and cooling efficiency that cannot meet high thrust-to-weight ratio aeroengines, etc., to achieve increased cooling area, The effect of improving the heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

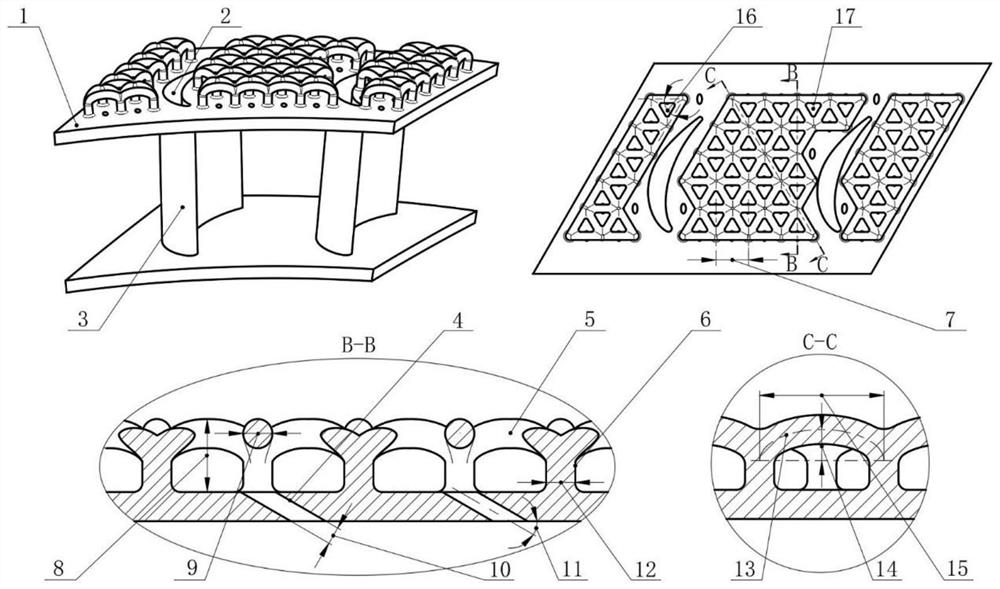

[0031] figure 2 It is a schematic diagram of a turbine guide vane with a curved branch-net cooling structure provided by an embodiment of the present invention. As shown in the figure, the curved branch network cooling structure of this embodiment is composed of two parts: a cylindrical support structure and a curved network connection structure. The cylindrical support structure in the curved branch network cooling structure is perpendicular to the outer surface of the turbine guide blade edge plate.

[0032] The cylindrical support structure in the curved branch cooling structure is defined by the diameter φD 1 The cylinders of =1 mm are arranged in an equilateral triangle, each cylinder is located at the vertices of the equilateral triangle, and the side length of the equilateral triangle is the distance L=3mm between two adjacent cylinders.

[0033] The curved network connection structure in the curved branch network cooling structure along the axis diameter φD 2 =1mm,...

Embodiment 2

[0036] The utility model relates to a turbine guide vane with a curved branch-network cooling structure, in which the cylindrical support structure is perpendicular to the outer surface of the edge plate of the turbine guide vane.

[0037] The cylindrical support structure in the curved branch cooling structure is defined by the diameter φD 1 = 2mm cylinders, arranged in a regular triangle, each cylinder is located at the apex of the regular triangle, the typical value of the side length of the regular triangle, that is, the distance L between two adjacent cylinders, is 4mm.

[0038] The curved network connection structure in the curved branch network cooling structure along the axis diameter φD 2 = 1-2 mm, the axis of the elliptical curved network connection structure is elliptical, the length of the major axis of the ellipse is L, and the length of the minor axis is 0.7L, with a typical value of 0.5L. The total height of the curved branch network cooling structure is H = 4m...

Embodiment 3

[0040] Considering that the structure will be applied in different working conditions, the working temperature is different, and the thermal expansion coefficient of the material is different, so two kinds of curved branch network cooling structures are provided. figure 2 It is an elliptical curved branch network cooling structure, Figure 6 It is a circular curved branch network cooling structure.

[0041] The circular curved branch network cooling structure is the case where the long and short axes of the ellipse are the same. In this structure, the branches connected between two adjacent cylindrical supports are all semicircular, and the axis is a semicircle with a radius of 0.5L. The cross-sections in each direction are typical values φD 2 = 1 mm circle. This structure takes into account the large difference in thermal expansion between the edge plate and the curved mesh connection structure in a high-temperature environment. The edge plate is directly in contact with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com