Method for lowering aspheric surface large-diameter hollow reflector adhesive stress

A large-diameter, mirror technology, applied in installation, optics, instruments, etc., can solve problems such as the relative displacement of the main mirror and the main mirror frame, and the deterioration of surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

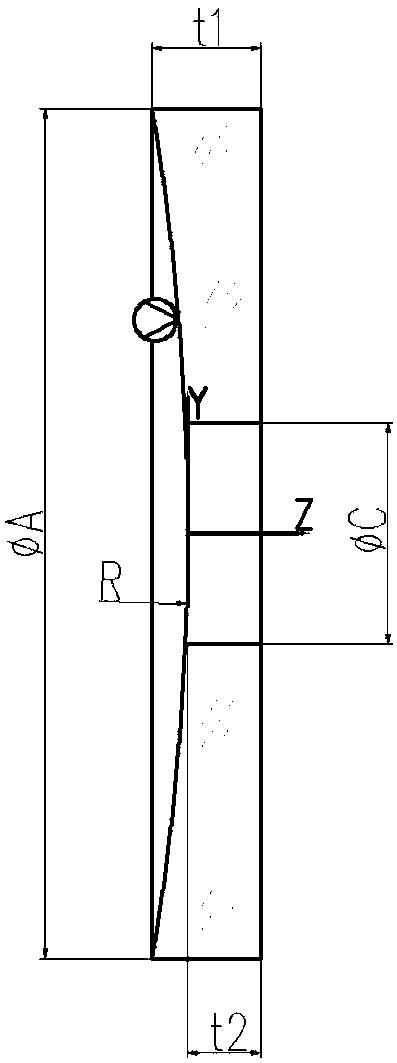

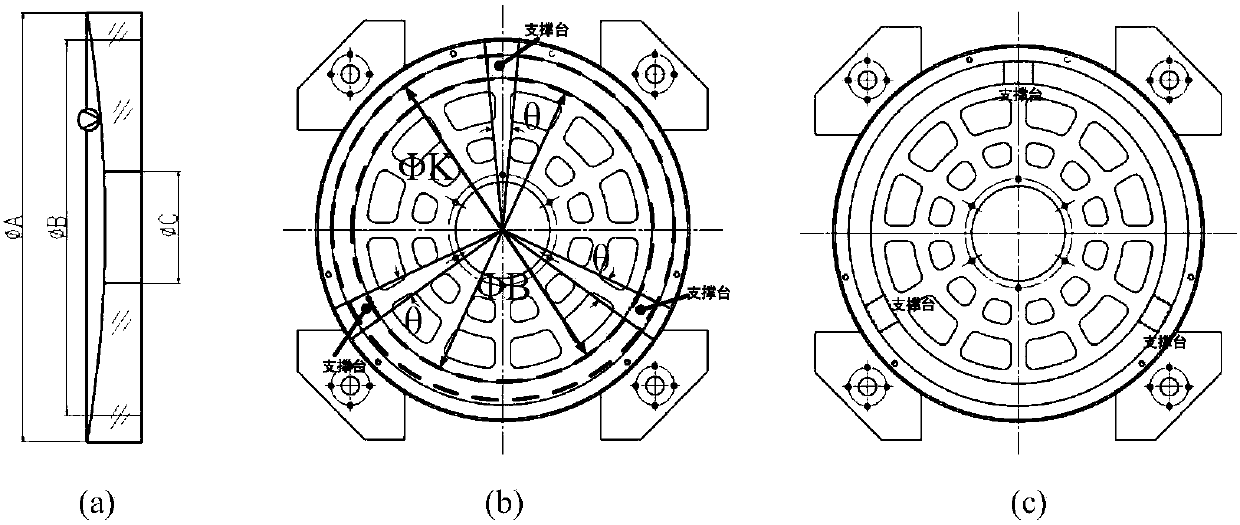

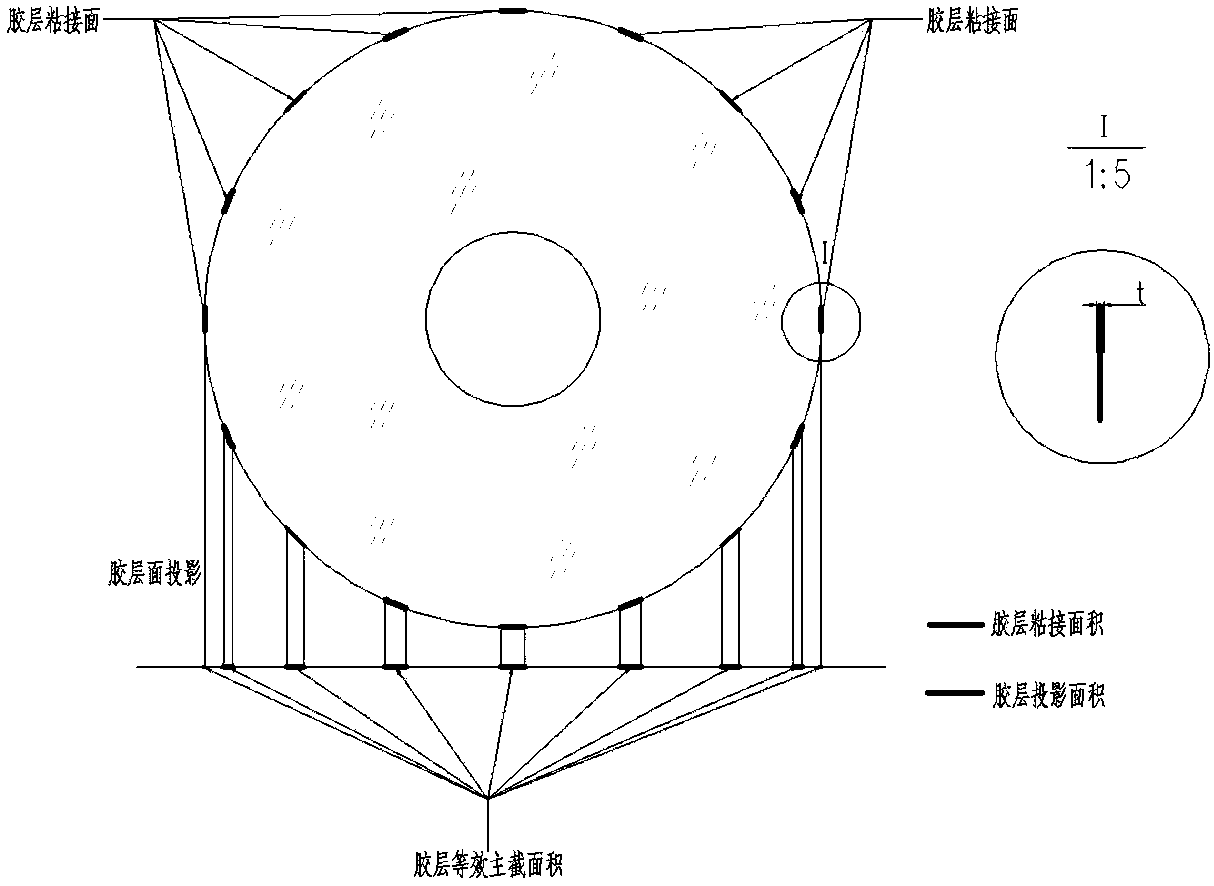

[0053] The Cassegrain system structure of a certain type of optoelectronic product is composed of a main reflector 1, a main mirror frame 2, a main mirror pressure plate 3, a pressure plate rubber pad 4, and a pressure plate screw 5, such as Figure 6 shown. The main reflector 1 adopts such as Figure 4 In the structure shown, the material of the main reflector is quartz glass, the aperture size is φ230mm, the weight is 2.1Kg, the hollow diameter φ65mm accounts for 1 / 3.5 of the aperture of the main reflector, the maximum thickness of the edge is 30.2mm, and the thickness of the hollow hole is 20mm. 2 / 3 of the thickness, and the aspect ratio of the thinnest part is 1 / 11.5. After the measurement, the main mirror assembly front type RMS = λ / 30 (λ = 632.8nm). The main reflector is assembled in the main mirror frame, and the main reflector is fixed by bonding. After the glue is poured, the main reflector is fixed with the main mirror pressure plate and the aviation rubber pad. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com