Magnetic recording medium, manufacturing method of magnetic recording medium, and magnetic recording and reproducing apparatus

一种磁记录介质、磁性层的技术,应用在磁记录、磁记录层、记录层的基础层等方向,能够解决恶化磁记录介质耐腐蚀性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

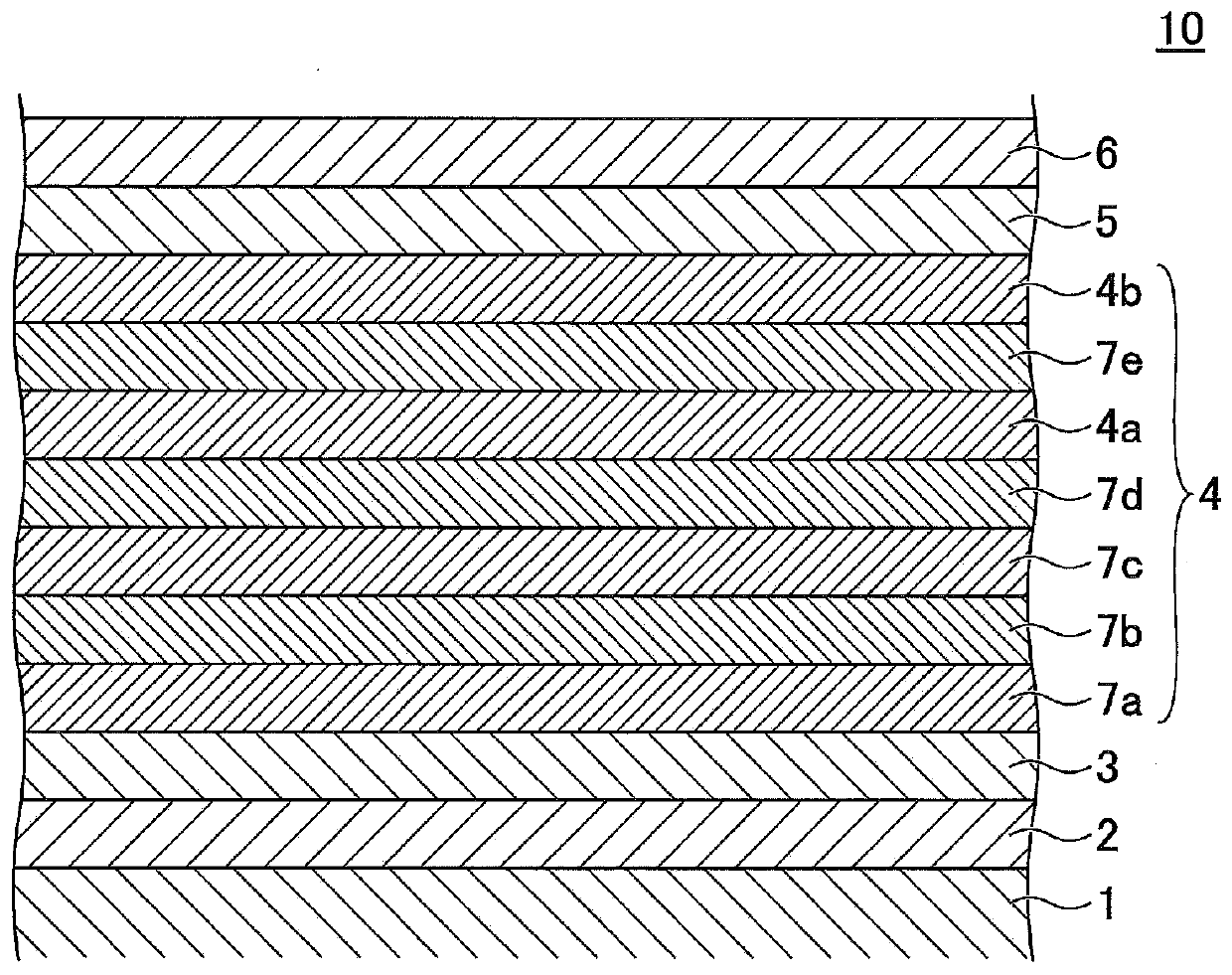

[0106] A magnetic recording medium was fabricated as follows.

[0107] The cleaned outer diameter of 2.5 inches glass non-magnetic substrate 1 (manufactured by HOYA company) is placed in the film formation chamber of DC magnetron (magnetron) sputtering device C-3040 (manufactured by ANELVA company), and the The film forming chamber is exhausted to an ultimate vacuum of 1×10 -5 After Pa, an adhesion layer with a thickness of 10 nm was formed on the non-magnetic substrate 1 using a Cr-50Ti {the content of Ti is 50 at %, and the remainder is Cr} target material.

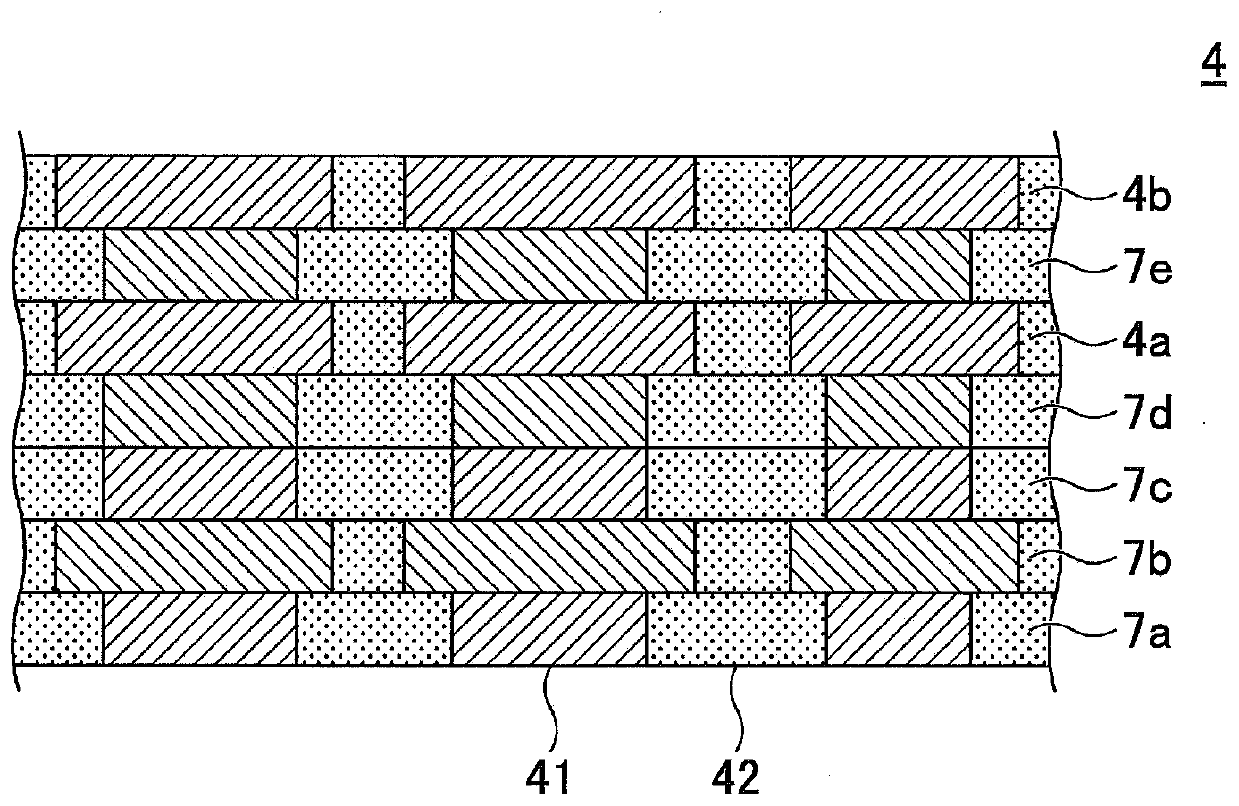

[0108] Next, use a Co-20Fe-5Zr-5Ta {the content of Fe is 20at%, the content of Zr is 5at%, the content of Ta is 5at%, and the rest is Co} target material, and the temperature of the non-magnetic substrate 1 is 100 °C or lower, a soft magnetic layer with a thickness of 25 nm is formed on the adhesive layer. Then, using a Ru target, a Ru layer with a thickness of 0.7 nm was formed on the soft magnetic layer. Next, usin...

Embodiment 2

[0119] A magnetic recording medium 10 was obtained in the same manner as in Example 1, except that a Co10Cr20Pt14Ti target was used to form a magnetic layer having a granular structure composed of 93(Co12Cr22Pt7Ti)-7(TiC) when forming the second magnetic layer 4b.

Embodiment 3

[0121] In addition to using the Co10Cr20Pt14Al target to form the second magnetic layer 4b formed by 97 (Co12Cr22Pt2Al)-3 (Al 4 C 3 ) except for the magnetic layer having a granular structure composed of ), a magnetic recording medium 10 was obtained in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com