Perpendicular magnetic recording medium, production process thereof, and perpendicular magnetic recording and reproducing apparatus

A perpendicular magnetic recording and perpendicular magnetic technology, applied in the direction of magnetic recording, magnetic recording layer, data recording, etc., can solve the problems of unstable recording magnetization, demagnetization and recording data loss, peak noise, etc., to achieve high-density recording , the effect of excellent noise characteristics, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

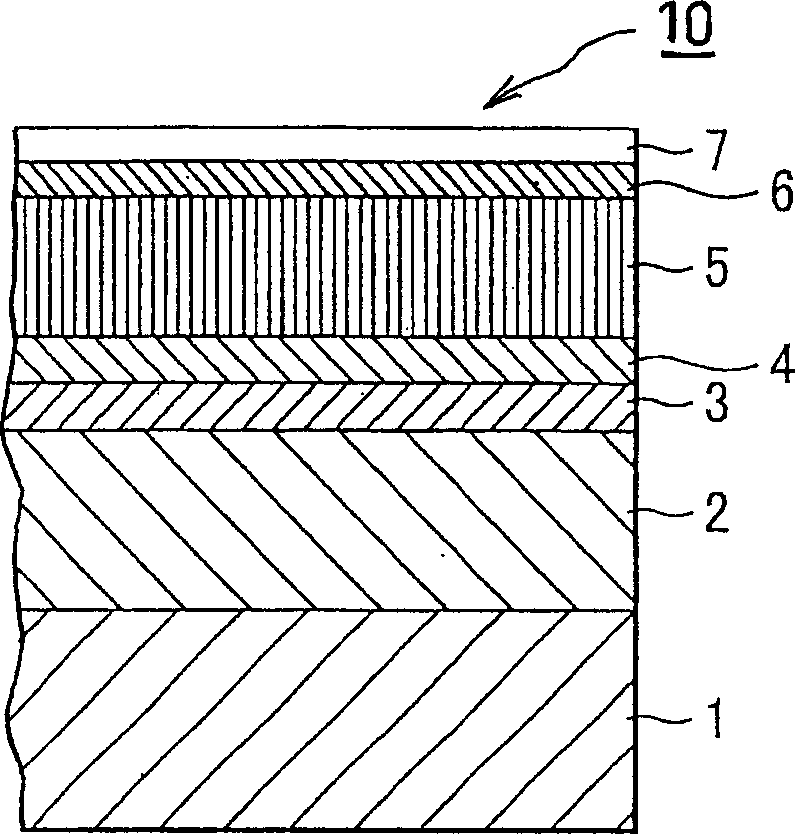

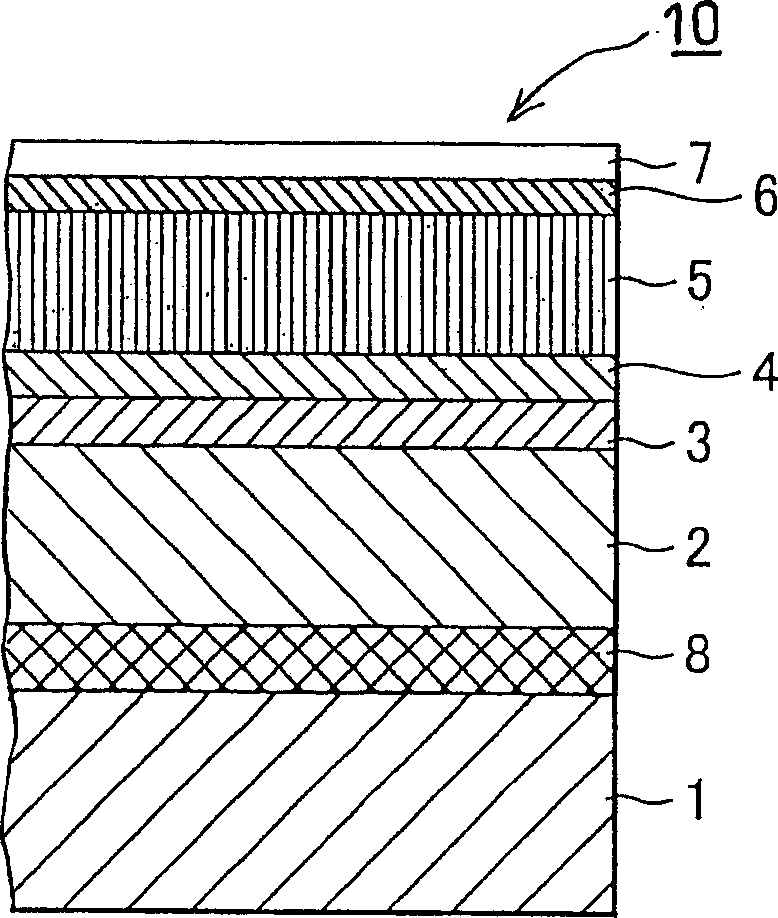

Method used

Image

Examples

example 1

[0102] A glass substrate with an average surface roughness (Ra) of 0.5nm or less is chemically cleaned, and then, by DC magnetron sputtering, an adhesive layer (thickness 10nm) consisting of a Ti film and a Ni film are sequentially formed. A seed layer (thickness 20 nm) was formed. Next, the obtained laminated product was subjected to conventional pretreatment, and then a CoNiFeP soft magnetic film (3000 nm in thickness) serving as an undercoat film was formed by using the electroless plating solution in Table 1.

[0103] Figure 5 An example of an apparatus 11 for forming a soft magnetic film is shown. The plating tank 18 containing the plating solution is placed in the water tank 12, and the glass substrate 20 on which the seed layer is formed and held in the plating solution in the plating tank 18 is immersed. On the substrate holder 19 provided with a rotation mechanism (not shown). The substrate holder 19 is vertically movable supported by the substrate holding hook 17...

example 2

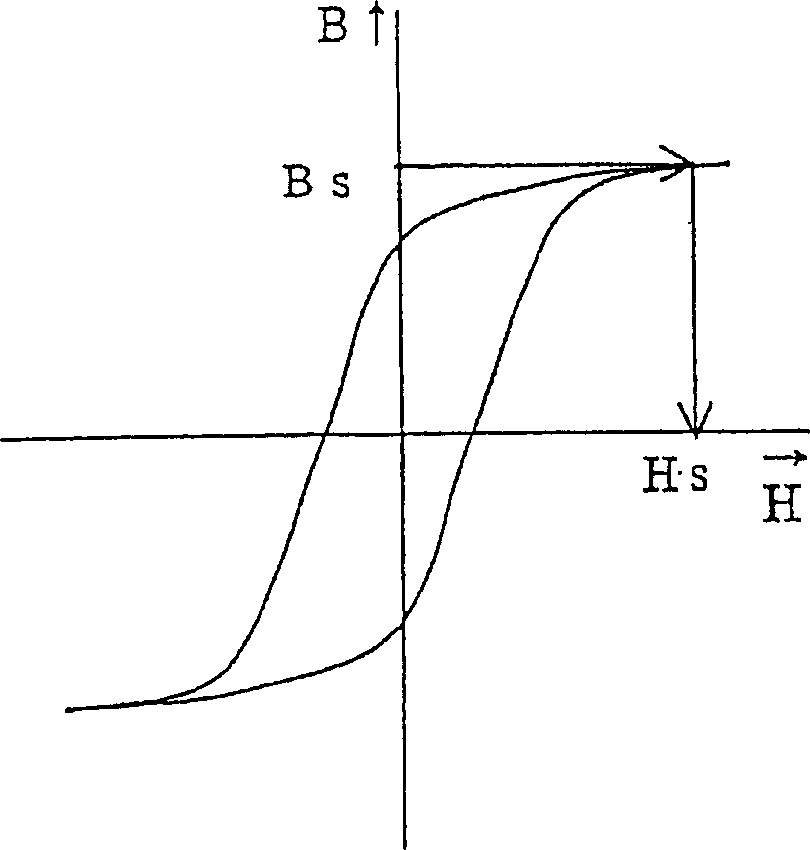

[0110] The procedure of Example 1 was repeated except that the strength of the external magnetic field applied in the plating was changed from 35G to 100G (neodymium-iron-boron magnet). Table 4 shows the results, namely, Bs, degree of isotropy, perpendicular magnetic anisotropy, MF-S / N ratio, and presence / absence of magnetic domain walls.

example 3

[0112] The process of Example 1 was repeated, except that the composition of the plating solution was changed to that shown in Table 2. Table 4 shows the results, namely, Bs, degree of isotropy, perpendicular magnetic anisotropy, MF-S / N ratio, and presence / absence of magnetic domain walls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com