Multijunction solar cell having patterned emitter and method of making the solar cell

A technology of solar cells and solar sub-cells, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as reducing the efficiency of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

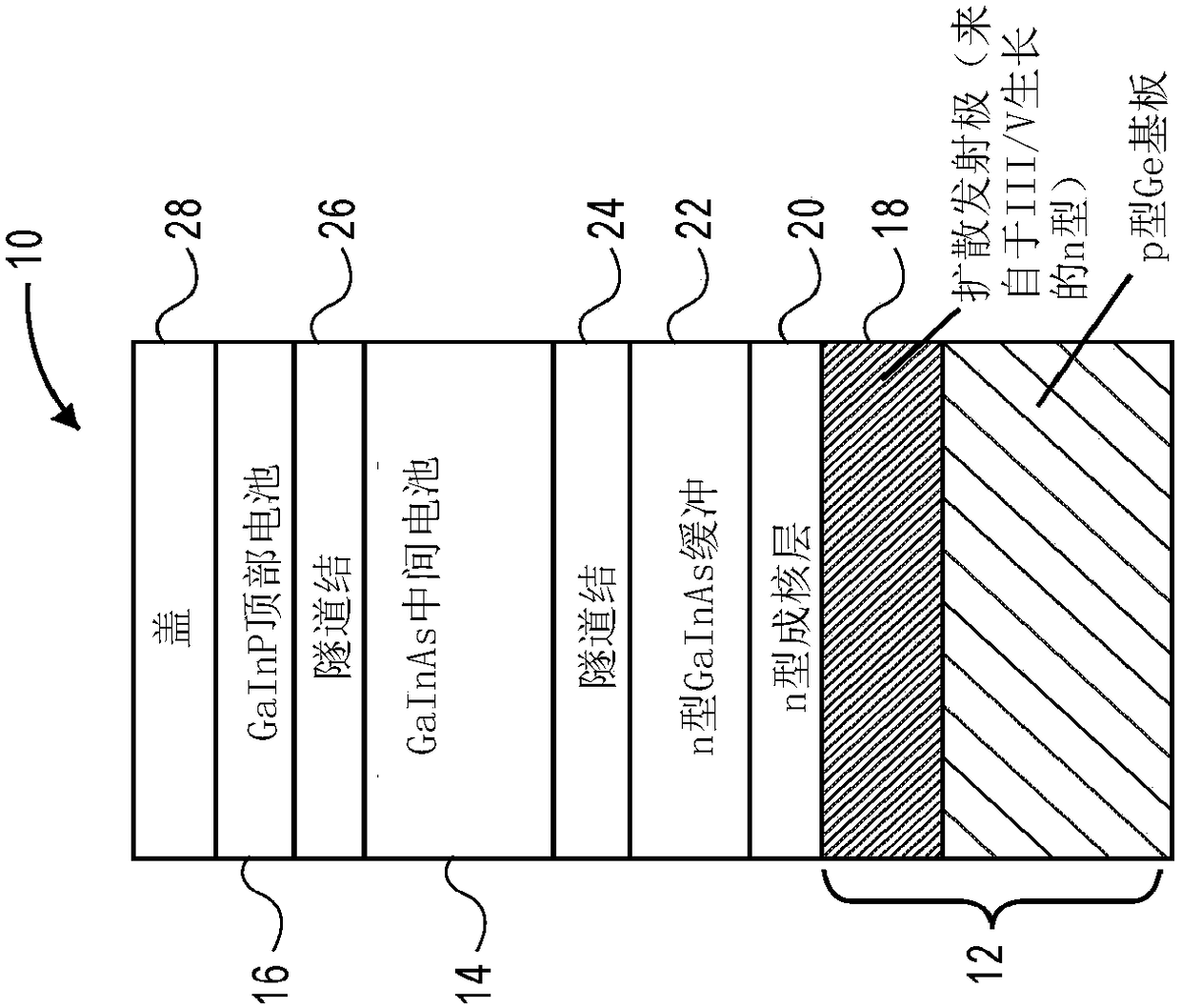

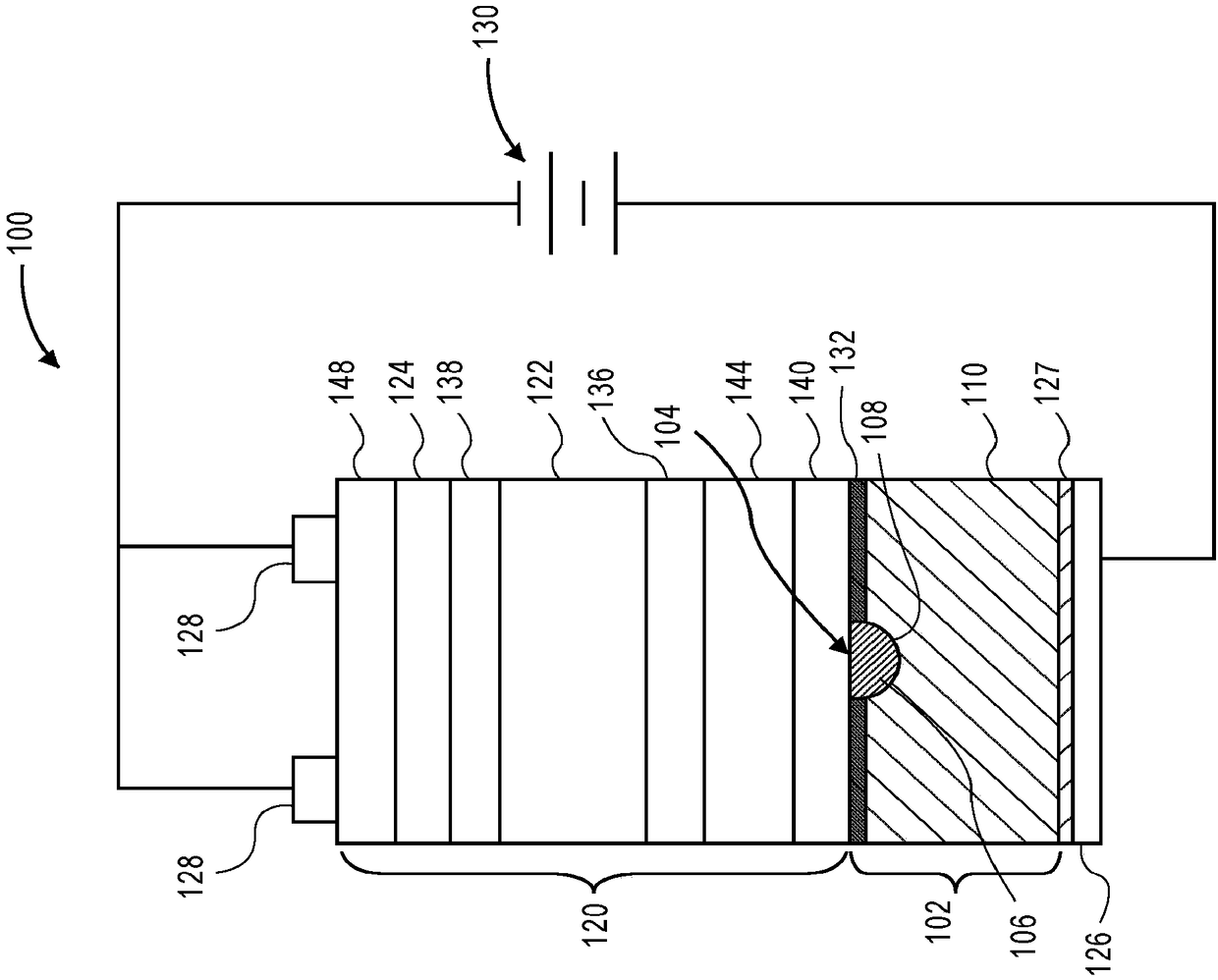

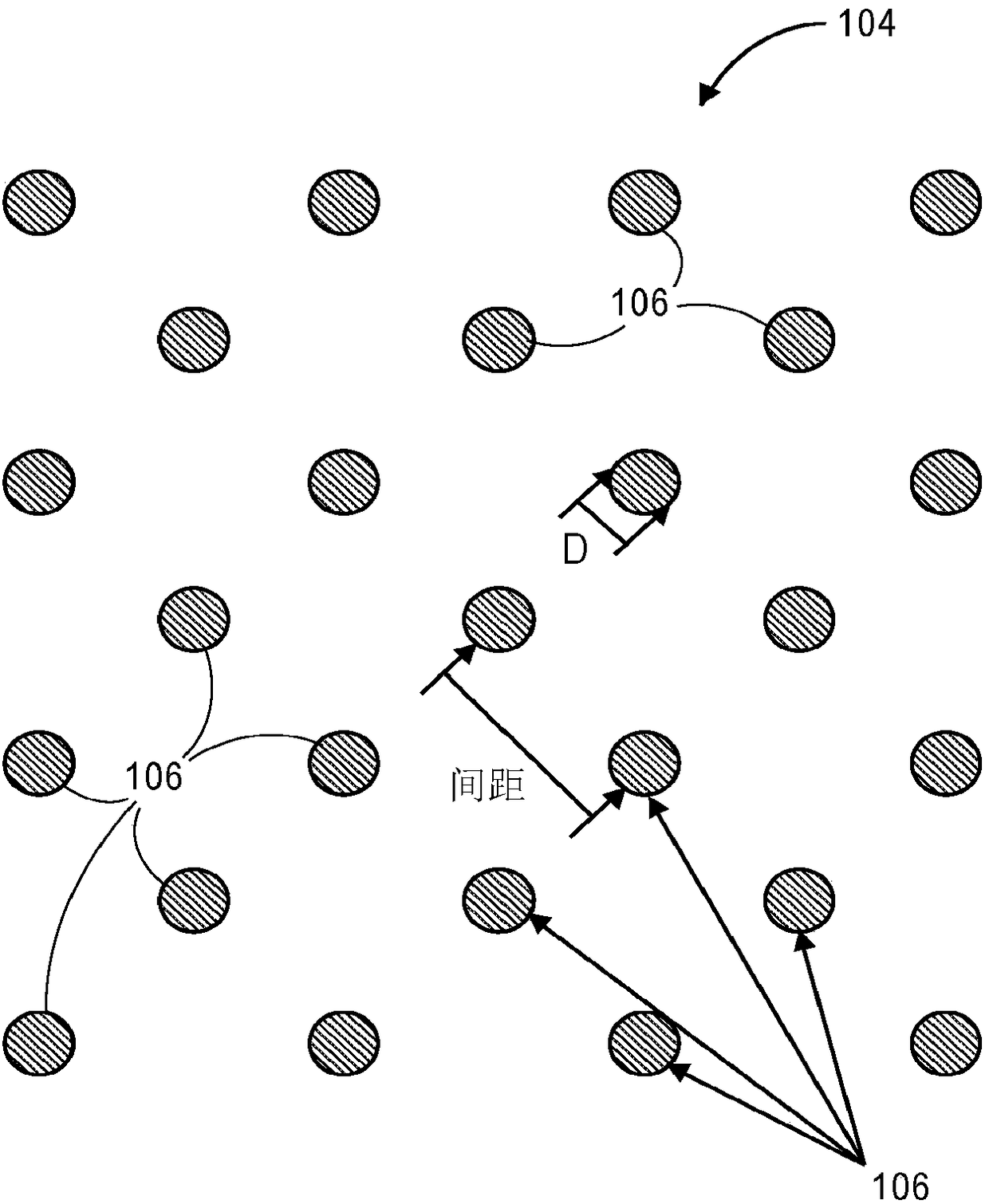

[0054] Embodiment 1. A multi-junction solar cell comprising: a base substrate comprising a Group IV semiconductor and a dopant of a first carrier type; a patterned emitter formed at a first surface of the base substrate, The patterned emitter includes a plurality of well regions doped with a dopant of the second carrier type in the Group IV semiconductor, the base substrate includes the patterned emitter forming the first solar subcell; and the upper structure includes One or more additional solar subcells above the first solar subcell.

Embodiment 2

[0055] Embodiment 2. The multi-junction solar cell of embodiment 1, further comprising a passivation layer at the first surface of the base substrate positioned between the patterned emitter well regions and comprising a second A carrier type dopant.

Embodiment 3

[0056] Embodiment 3. The multijunction solar cell of embodiment 1 or 2, wherein the Group IV semiconductor comprises a material selected from germanium and silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com