Modified lithium-ion battery cathode material and preparation method thereof

A technology of lithium ion battery and positive electrode material, applied in the field of lithium ion battery positive electrode material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

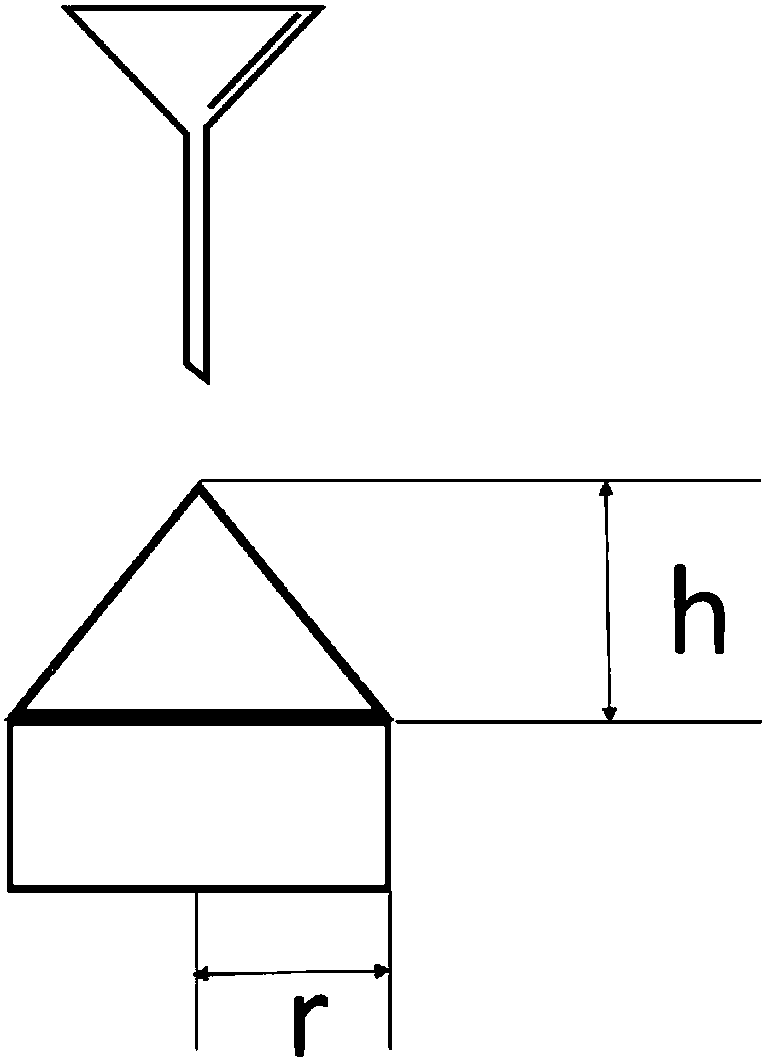

Method used

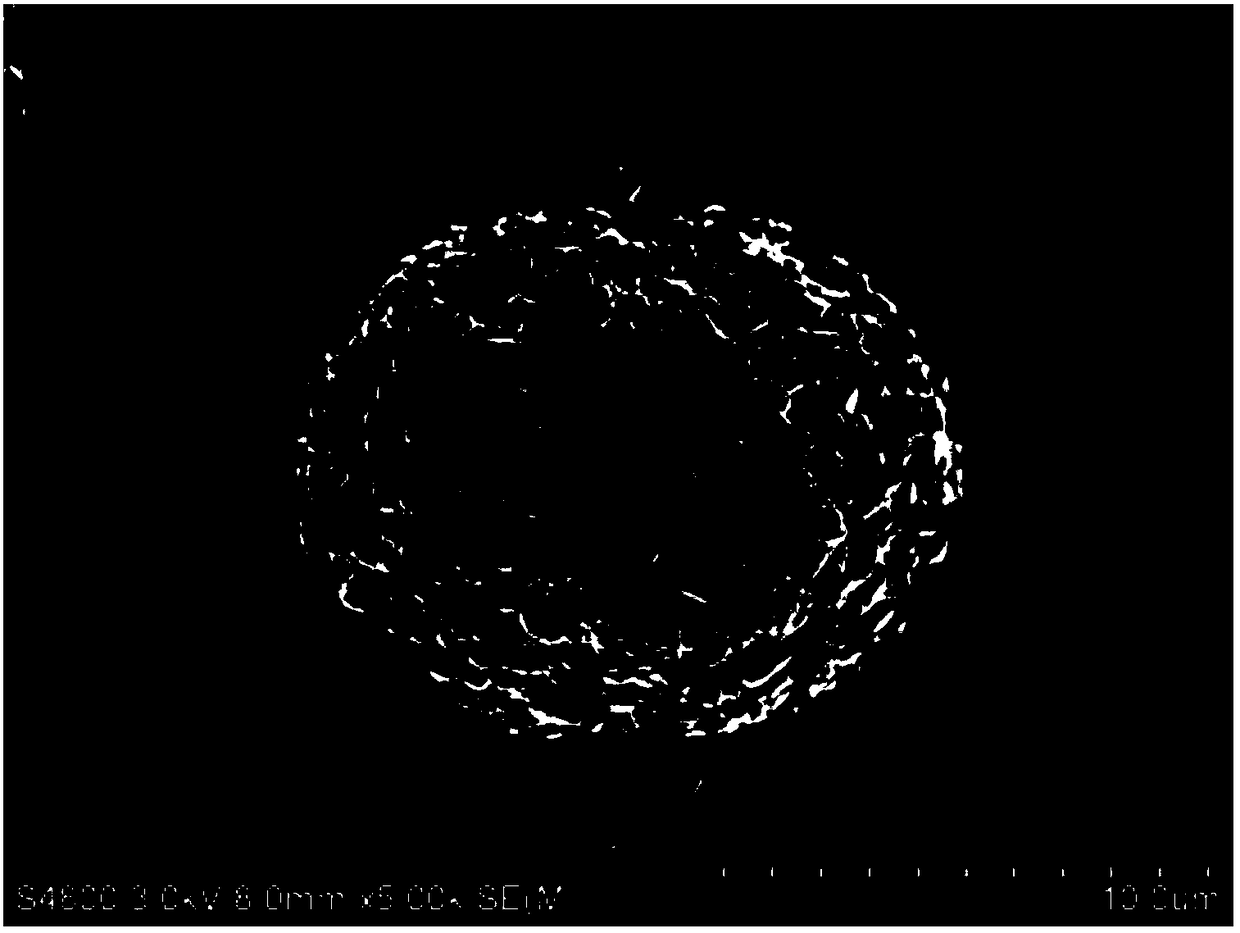

Image

Examples

Embodiment 1

[0074] In the 5t median particle size D50 is 6 μm lithium-ion battery positive electrode material Li (Ni 0.5 co 0.2 mn 0.3 )O 2 In, add 5kg of SiO with a particle size of 15nm 2 , crushed until the average particle size of the lithium-ion battery positive electrode material is 6-7 μm, the speed of the gravity-free mixer is 40r / min, iron removal, batch mixing for 2 hours, and passing through a 300-mesh ultrasonic vibrating sieve to obtain the final product.

[0075] The prepared sample was charged and discharged at a negative electrode of carbon at a high temperature of 55°C and 1C, and the capacity retention rate was 94.5% after 200 cycles.

[0076] For lithium 2032, the capacity of the button battery is 164.5mAh / g at 0.2C and 156mAh / g at 1C.

Embodiment 2

[0078] Lithium-ion battery cathode material Li(Ni) with a median particle size D50 of 3 μm at 3t 0.5 co 0.2 mn 0.3 )O 2 In, add 10kg of SiO with an average particle size of 30nm 2 , crushed until the particle size of the lithium-ion battery positive electrode material is 3-4 μm, the speed of the non-gravity mixer is 40r / min, iron is removed, mixed in batches for 2 hours, and the final product is obtained by a 300-mesh ultrasonic vibrating screen.

[0079] The prepared sample was charged and discharged at 55°C at a negative electrode temperature of 1C, and the capacity retention rate was 94% after 200 cycles.

[0080] For lithium 2032, the capacity of the button battery is 165mAh / g at 0.2C and 157mAh / g at 1C.

Embodiment 3

[0082] Synthesized Li(Ni 0.5 co 0.2 mn 0.3 )O 2 After 5t, add 15kg of SiO with a particle size of 30nm 2 , crushed until the particle size of the positive electrode material of the lithium-ion battery is 3-4 μm, the speed of the cone mixer is 30r / min, iron is removed, mixed in batches for 2 hours, and passed through a 300-mesh ultrasonic vibrating sieve to obtain the final product.

[0083] The prepared sample was charged and discharged at 55°C at a negative electrode temperature of 1C, and the capacity retention rate was 94% after 200 cycles.

[0084] For lithium 2032, the capacity of the button battery is 164mAh / g at 0.2C and 155mAh / g at 1C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com