Jack device directly driven by frameless permanent magnet synchronous motor

A permanent magnet synchronous motor and permanent magnet synchronous technology, applied to synchronous motors with stationary armatures and rotating magnets, electromechanical devices, lifting devices, etc., can solve the problem of low lifting height of hydraulic jacks, complex screw jack structures, Complicated structure and other issues, to achieve the effect of flexible selection, simple structure, and simplified driving mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

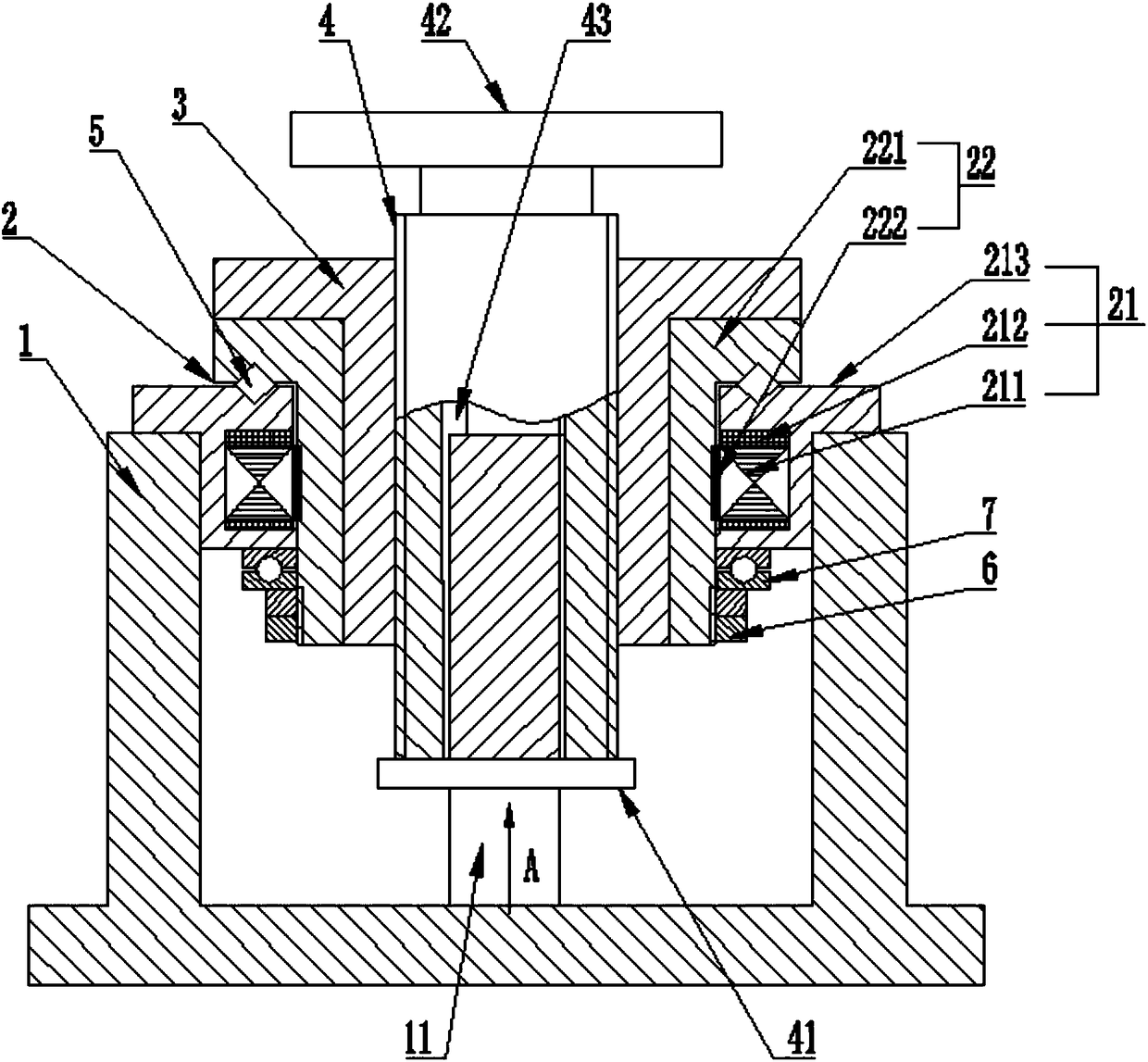

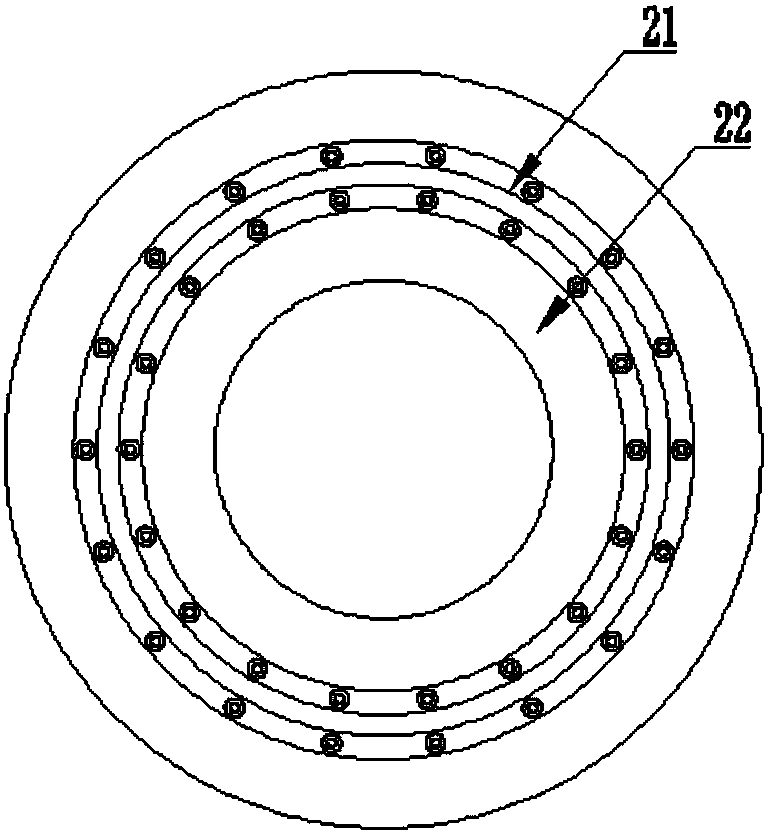

[0043] Such as Figure 1~5 As shown, a jack device directly driven by a frameless permanent magnet synchronous motor includes a jack base 1 and a motor 2, the motor 2 is a frameless permanent magnet synchronous direct drive motor, and the frameless permanent magnet synchronous The direct drive motor includes a stator assembly 21 and a rotor assembly 22, the stator assembly 21 includes a first stator core 211 and a first stator winding 212 wound on the first stator core 211, the first stator The iron core 211 is an integrally formed annular column; the stator assembly 21 of the frameless permanent magnet synchronous direct drive motor is fixedly connected to the jack base 1; the rotor assembly 22 is connected to the screw rod 4 of the jack through a nut 3 .

[0044] The present invention uses a frameless permanent magnet synchronous motor to directly drive the screw 4, and the rotor assembly 22 rotates through a nut 3 and is connected to the screw 4 of the jack. When the motor...

Embodiment 2

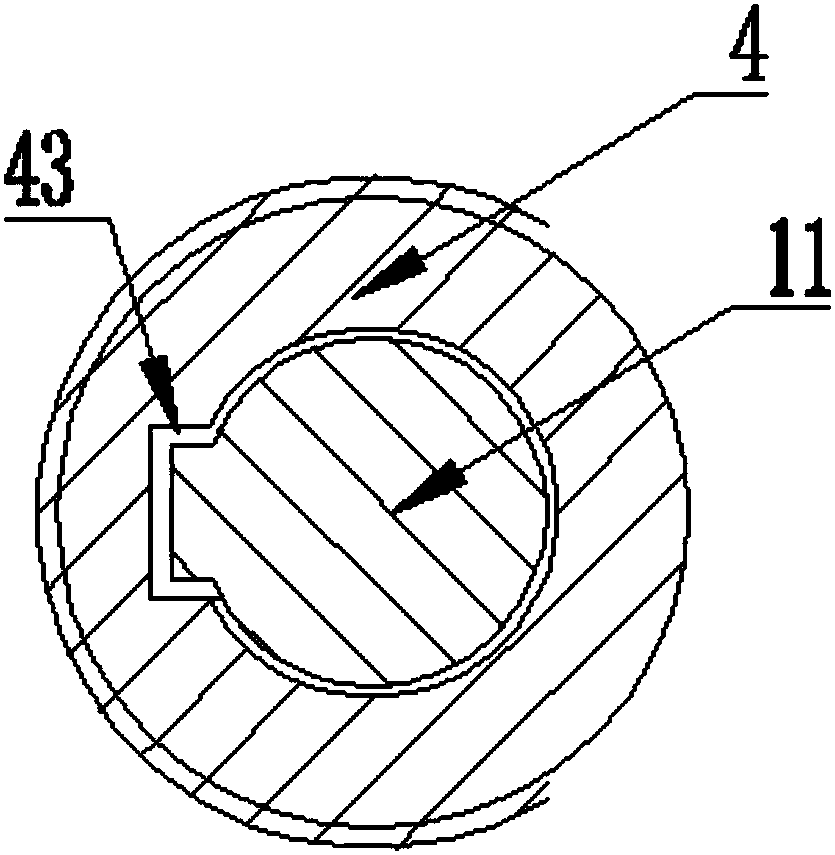

[0052] Such as Figure 6-8 As shown, a jack device directly driven by a frameless permanent magnet synchronous motor. The structure and principle of this embodiment are similar to those of Embodiment 1. The difference between this embodiment and Embodiment 1 is that the cross-section It is cross-shaped or square or the guide rod 11 is a cylinder, and four protrusions are arranged in the circumferential direction; the guide rod 4 is provided with a slideway 43 adapted to the guide rod.

Embodiment 3

[0054] Such as Figure 9 As shown, a jack device directly driven by a frameless permanent magnet synchronous motor, the structure and working principle of this embodiment are similar to that of embodiment 1 or embodiment 2, and the difference with embodiment 1 or embodiment 2 is that the A cooling unit 12 is provided on the inner wall of the jack base 1 in the circumferential direction. When the motor is running, it will generate a lot of heat, which affects the normal operation of the equipment. The cooling unit can quickly take away the heat to ensure the stable operation of the equipment.

[0055] The cooling unit 12 is a cooling water pipe. The circulating water flowing inside the cooling water pipe can take out the heat generated by the equipment in time, so that the equipment can maintain a very stable and suitable temperature, and the cooling effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com