Comb body of pet comb and pet comb

A comb and pet technology, applied in the field of pet combs, can solve the problems of unable to cut knotted hair, cutting unknotted hair, and stuck broken hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

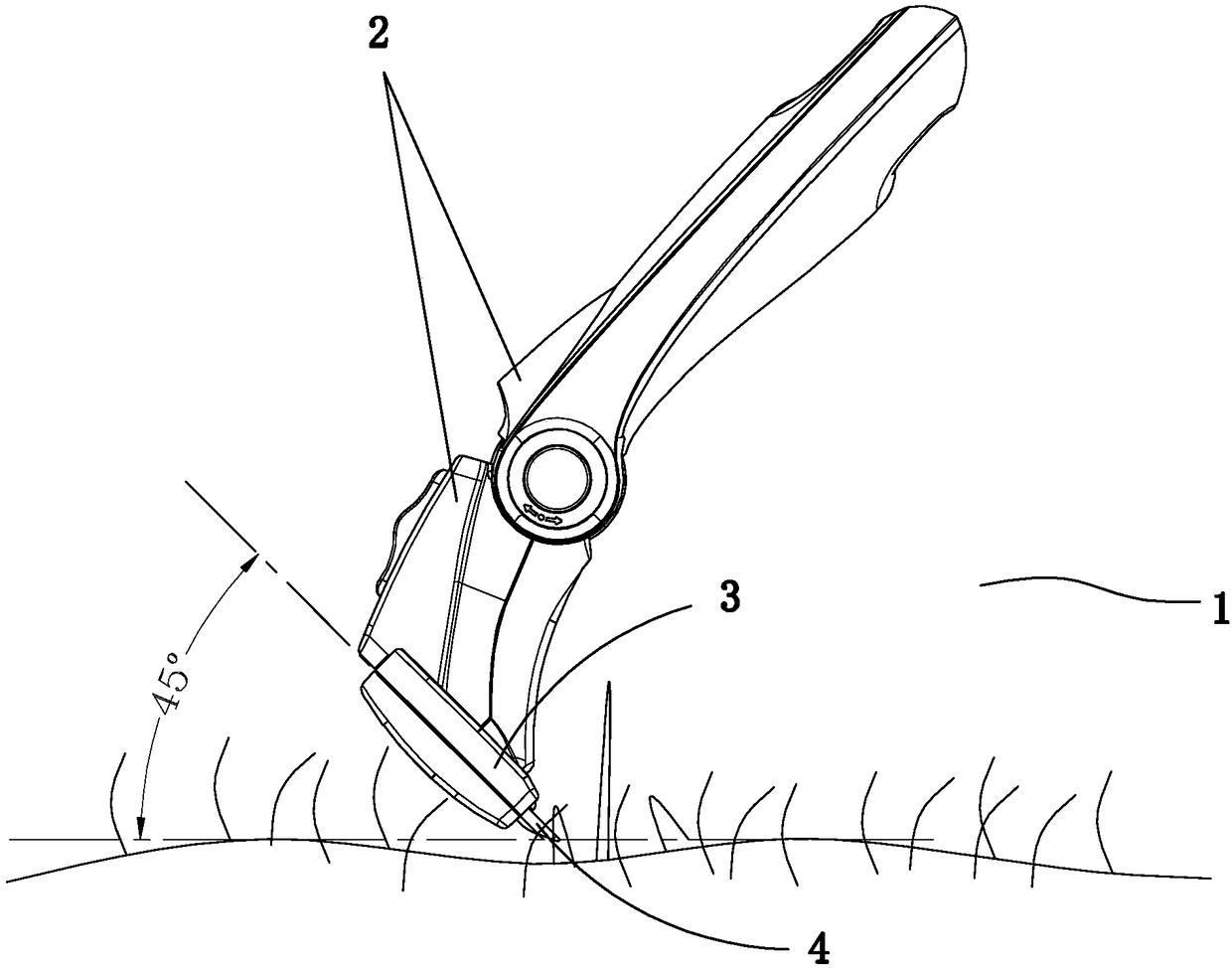

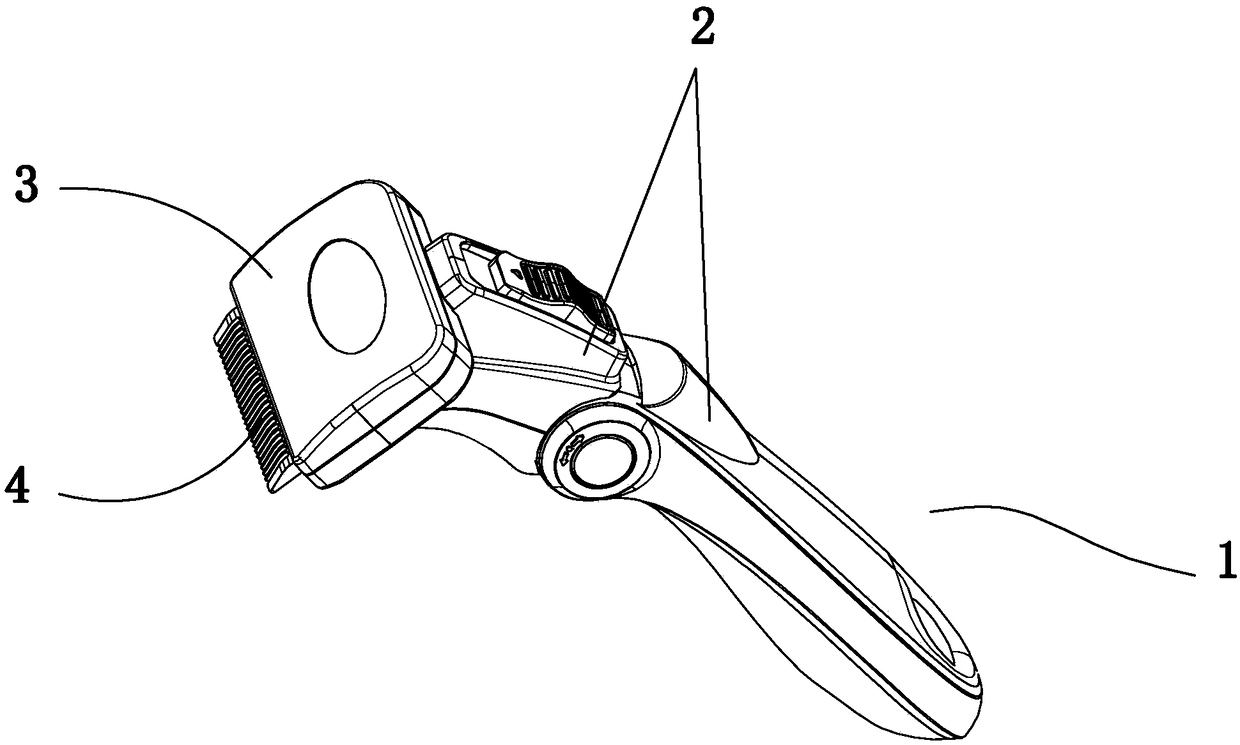

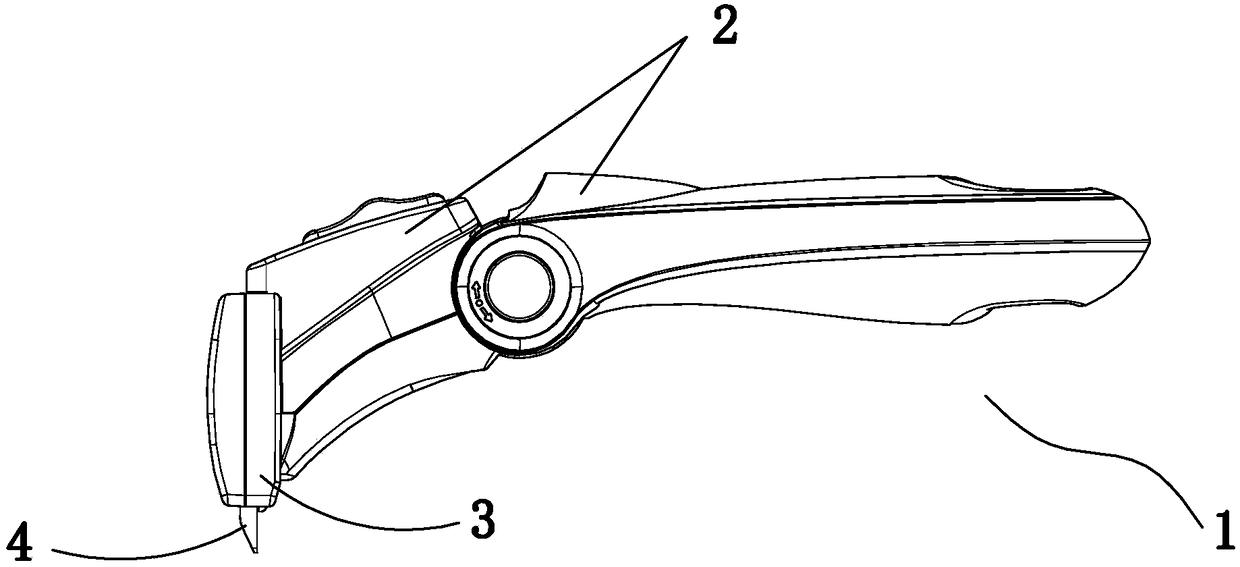

[0047] Embodiment one: if Figure 1 to Figure 7 As shown, the pet comb 1 includes an installation head 3 and a handle assembly 2, the installation head 3 is connected to the handle assembly 2, the comb body 4 is loaded into the installation head 3, and the back of the plate-shaped base 41 faces the comb comb. The movement direction of the hair is consistent, such as Figure 8 and Figure 9 As shown, the comb body 4 includes a plate-shaped base 41 and a row of strip-shaped comb teeth 42 of metal material at the front end of the plate-shaped base 41. Each strip-shaped comb tooth 42 is provided with a direction consistent with the direction of movement of the comb when combing hair. The cutting blade 421, when combing the hair of the pet, the moving direction of the comb is consistent with the direction of the blade, so that the knotted hair can be cut off easily. By applying a certain force, the connecting part of the hair can be cut off, and at the same time, the unknotted ha...

Embodiment 2

[0053] Embodiment two: if Figure 10 and Figure 11 As shown, other parts are basically the same as the embodiment, except that the shape of the cutting blade 421 is different. The cutting blade 421 of the second embodiment is a linear cutting blade, and the linear blade is positioned at the back of the comb body, that is, when combing hair with the comb. direction of motion is the same.

[0054] Such as Figure 10 As shown, the straight cutting edge is the middle edge of two symmetrical inclined surfaces. The smaller the angle between the two inclined surfaces, the sharper the cutting edge 421 is, otherwise, the blunter the cutting edge 421 is.

[0055] Such as Figure 11 , Figure 12 and Figure 20 As shown, the plate-shaped base 41 is made of plastic material, and the rear end of each strip-shaped comb tooth 42 has an assembly portion 44 , and the assembly portions 44 of the strip-shaped comb teeth 42 are independently assembled and fixed into the plastic material base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com