Train wheel rotary forging forming method

A train wheel and swing rolling machine technology, which is applied in the direction of wheels, web-type wheels, vehicle parts, etc., to achieve the effects of reducing equipment tonnage, small deformation force, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with accompanying drawing.

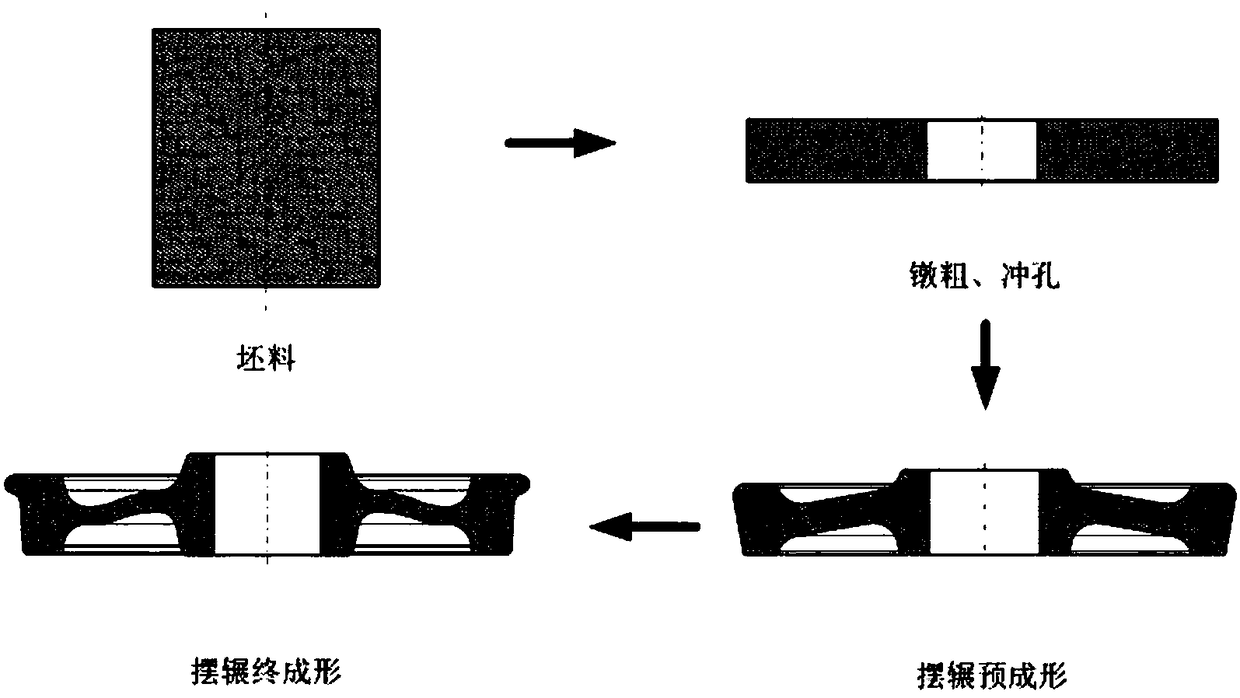

[0026] a. The continuous casting billet is cut to obtain a Ф380×432mm billet and heated to 1200°C;

[0027] b. Press preform: Upsetting and punching the blank on a 50MN press to obtain a preform. The size of the preform is: outer diameter Ф846mm, inner diameter Ф198mm, thickness 86.9mm;

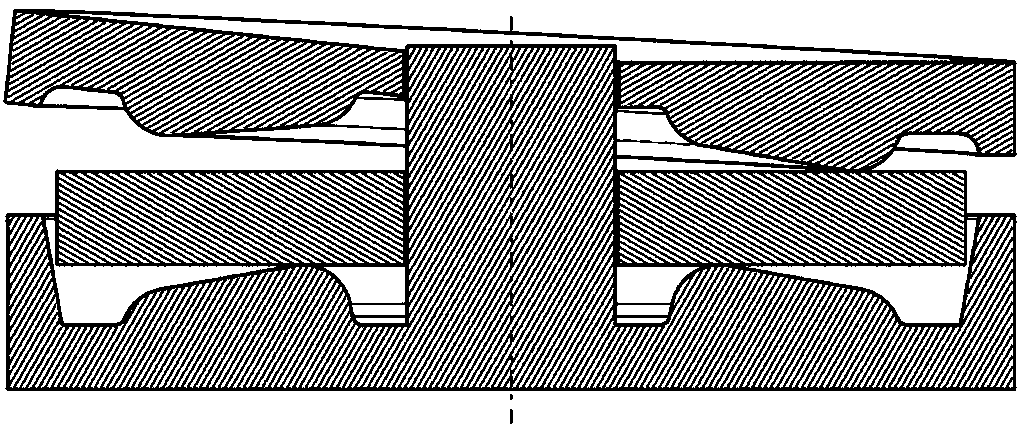

[0028] c. Rotary rolling preforming: preforms are obtained on the first rotary rolling machine. The preformed blanks need to be reasonably distributed to the metal at the web, hub, and rim, so that the metal can be completely formed when the rotary rolling is finally formed. Fill the mold cavity;

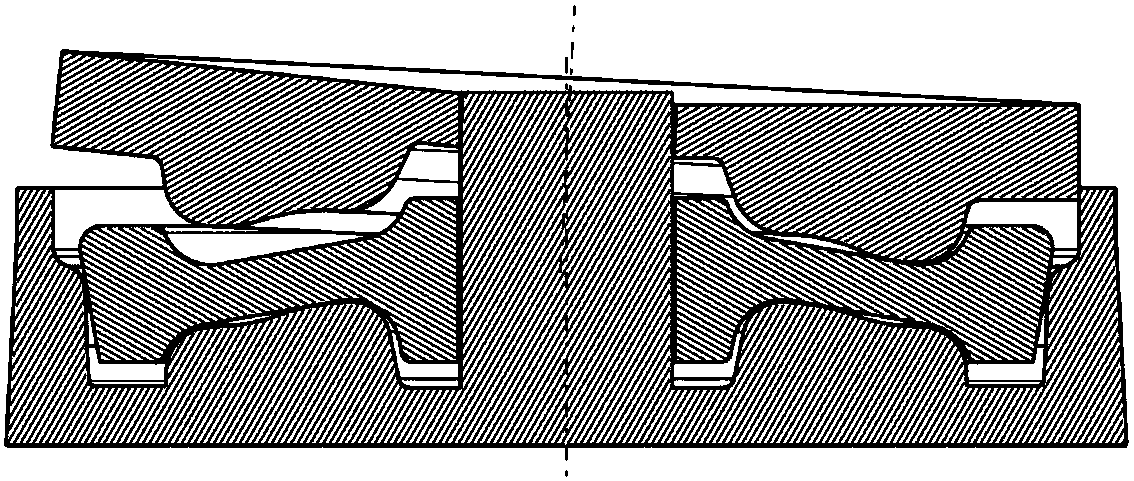

[0029] d Rotary rolling final forming: the heated preform is finally formed on the second rotary rolling machine to obtain the train wheel rotary rolling piece.

[0030] The specific operation of step c in this embodiment is as follows: put the preform into the lower mold of the first swing rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com