Miniature heat dissipation system

A heat dissipation system and miniature technology, which can be used in decoration through conduction and heat transfer, cooling/ventilation/heating transformation, electrical equipment structural parts, etc. To solve the effect of easy to produce eccentric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

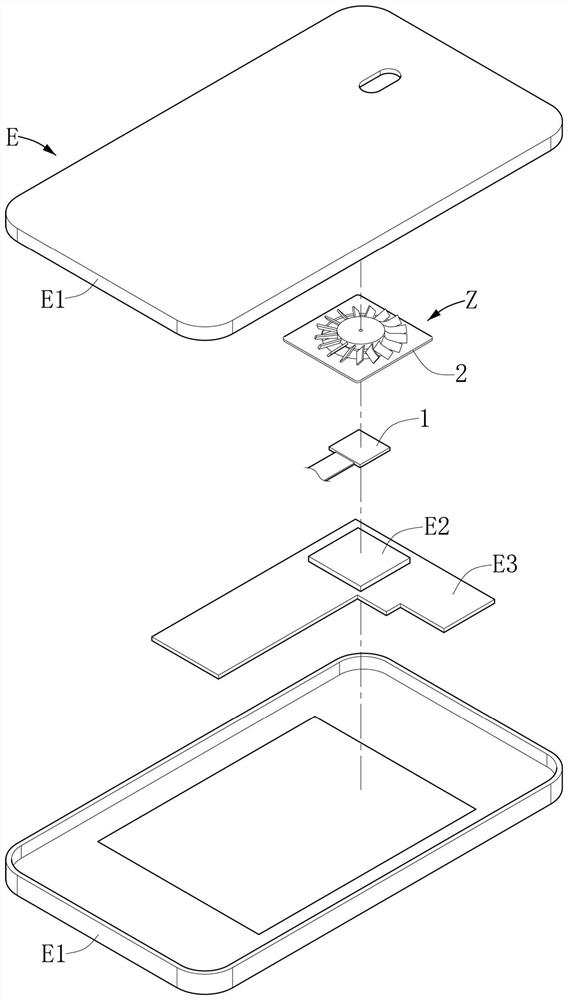

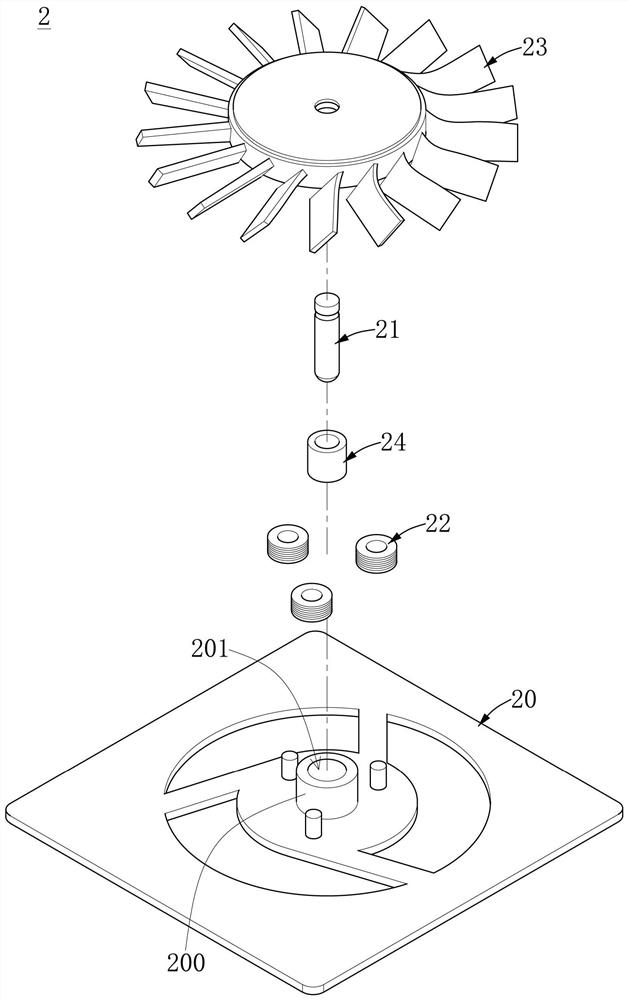

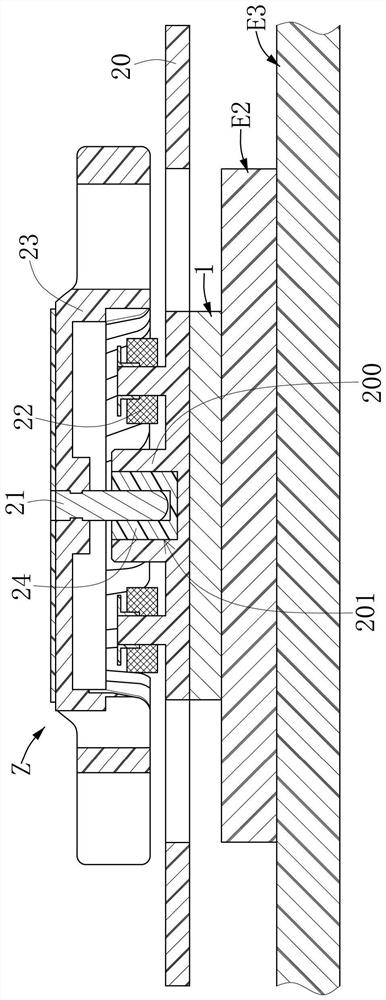

[0030] see Figure 1 to Figure 4 , are respectively a three-dimensional schematic diagram, a partial cross-sectional schematic diagram, an exploded schematic diagram of a heat dissipation module, and a functional block diagram of the micro cooling system according to the first embodiment of the present invention. As shown in the figure, the first embodiment of the present invention provides a miniature heat dissipation system Z, which is suitable for an intelligent communication device E. The intelligent communication device E includes a housing element E1 and a processing element E2 located in the housing element E1. The cooling system Z includes a sensing module 1 , a cooling module 2 and a control module 3 . The sensing module 1 is disposed on the processing element E2, and the sensing module 1 detects the temperature of the processing element E2 to generate at least one piece of temperature information. The heat dissipation module 2 includes a base plate unit 20 , a rotor...

no. 2 example

[0041] see Figure 5 and Figure 6 , are respectively the first structural schematic diagram and the second structural schematic diagram of the micro cooling system of the second embodiment of the present invention, and please refer to Figure 1 to Figure 4 . As shown in the figure, the operation mode of the same components of the miniature heat dissipation system of this embodiment is similar to that of the above-mentioned first embodiment, and will not be repeated here. It is worth noting that in this embodiment, the micro heat dissipation system Z further includes a heat conduction module 4 , and the heat conduction module 4 includes a heat absorption unit 40 , a conduit unit 41 and a heat release unit 42 . The heat absorption unit 40 is disposed on the processing element E2. One end of the duct unit 41 is connected to the heat absorption unit 40 . The heat release unit 42 is connected to the other end of the conduit unit 41 . Wherein, the heat absorption unit 40 absor...

no. 3 example

[0046] see Figure 7 , is the functional block diagram of the miniature cooling system of the third embodiment of the present invention, and please refer to it together Figure 1 to Figure 6 . As shown in the figure, the operation mode of the same components of the micro cooling system of this embodiment is similar to that of the micro cooling systems of the above-mentioned embodiments. It further includes a charging module 5, the charging module 5 includes a plurality of power generation units 50, the plurality of power generation units 50 are arranged on the other side of the substrate unit 20, and surround the rotor unit 21, and the plurality of power generation units 50 are electrically connected to the control module 3 and the intelligent The power supply element E4 of the type communication device E, the plurality of power generation units 50 generate electric energy according to the rotation of the rotor unit 21, and the plurality of power generation units 50 transmit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com