Device for automatically cutting and making plastic woven bags

An automatic technology for plastic woven bags, applied in the field of slitting and sewing plastic woven bags, can solve the problems of long transmission time of woven bags, affecting the quality of finished products, time waste, etc., to facilitate packaging processing, speed up cutting and sewing, and reduce measurement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

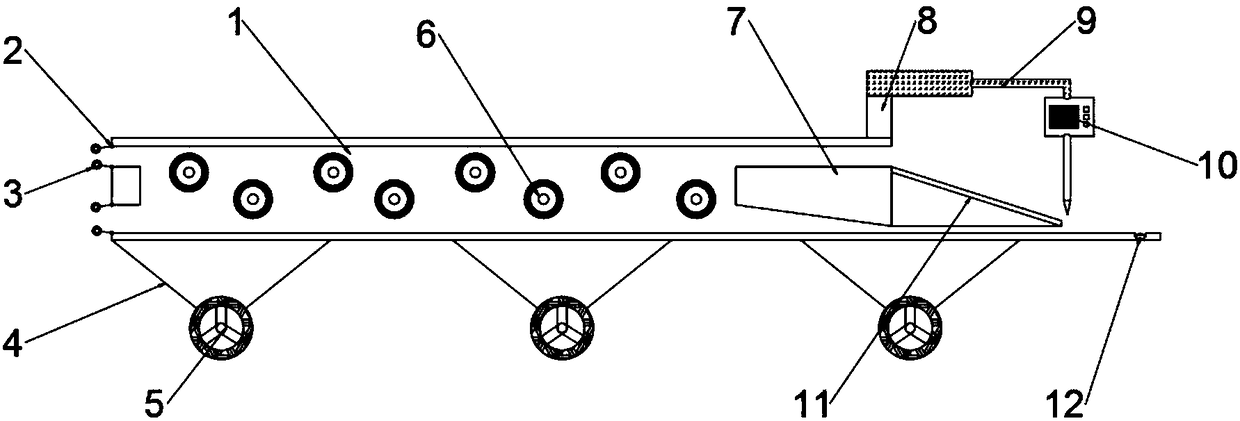

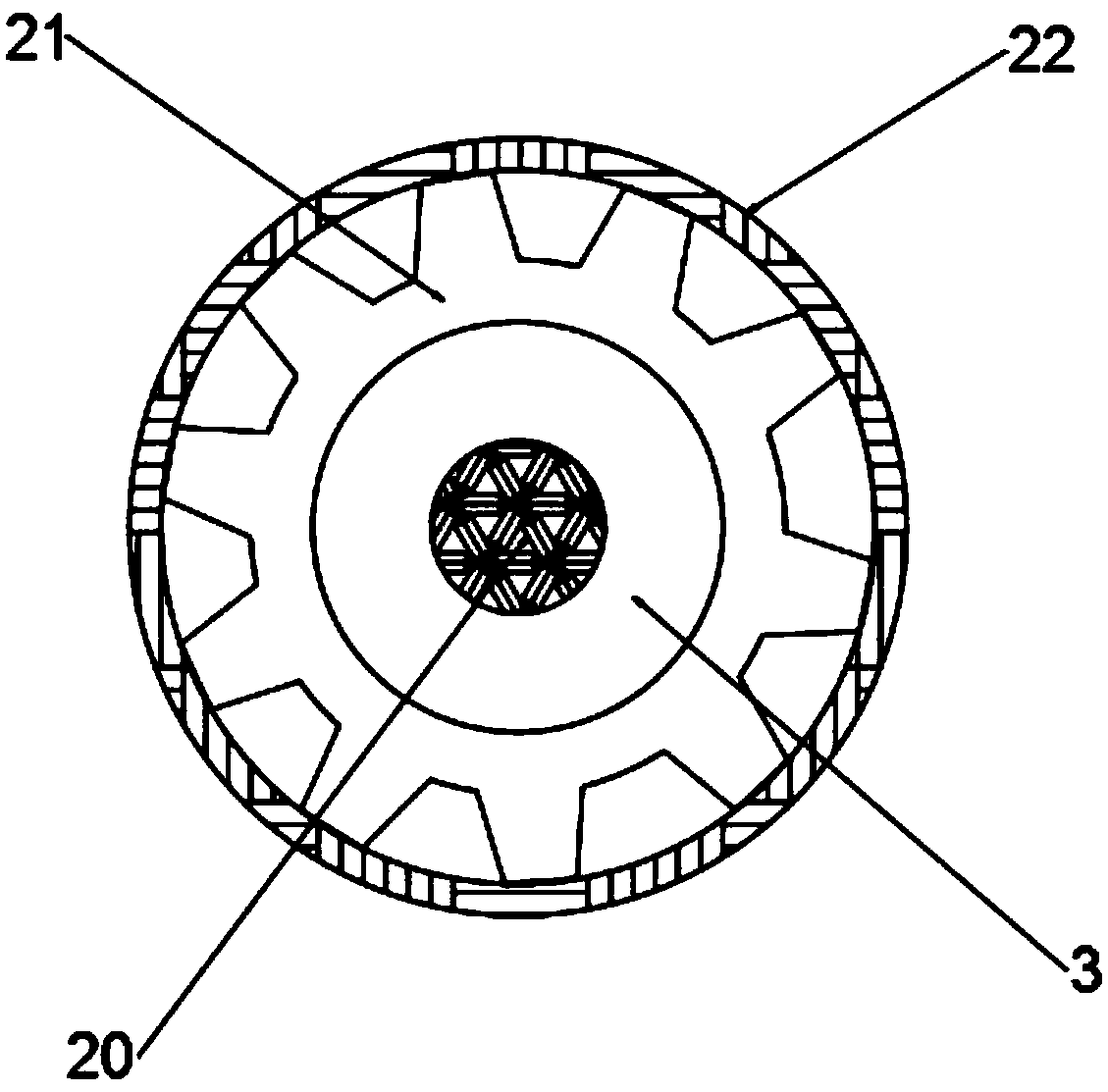

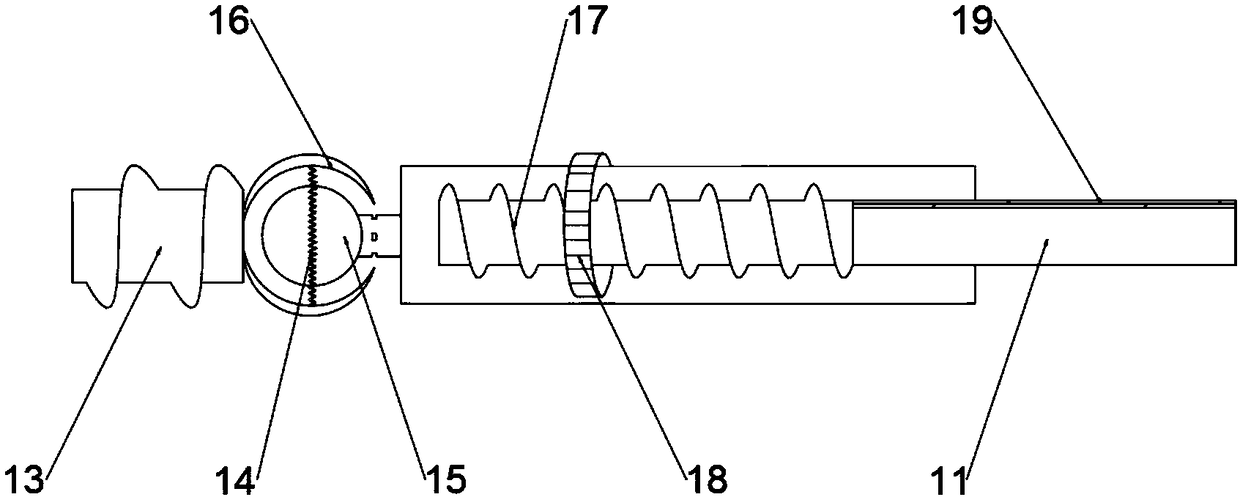

[0019] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an automatic cutting and sewing bag making device for plastic woven bags, which includes a machine table 1, a movable shaft 2, an extrusion wheel 3, a support rod 4, a wheel 5, a propulsion wheel 6, and a connecting plate 7. Connecting post 8, telescopic rod 9, slitter 10, misalignment plate 11, counter 12, connecting screw 13, return spring 14, movable ball 15, limiting leaf 16, telescopic screw 17, adjusting ring 18, length identification sticker 19. Motor 20, gear 21 and rubber ring 22. A movable shaft 2 is installed on one side of the machine table 1, an extrusion wheel 3 is connected to one side of the movable shaft 2, and a motor 20 is installed inside the extrusion wheel 3, and one side of the motor 20 is installed There is a gear 21, a rubber ring 22 is arranged outside the gear 21, a push wheel 6 is arranged on one side of the rubber ring 22, a support rod 4 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com