Bi-directional doctor blade unit for textile printing machines

A technology of scraper device and printing machine, which is applied to the configuration of textile material equipment, printing machines, rotary printing machines, etc. It can solve the problems of uneven scraping liquid, residual liquid flow, and wear of the roller surface, so as to achieve ink scraping or scraping Uniform, smooth liquid circulation, stable color and hue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and the enumerated implementation manners. It should be noted that any technical features and any technical solutions in this embodiment do not limit the protection scope of the present invention, and the protection scope of the present invention should include any equivalent or replacement technology that can be imagined by those skilled in the art without creative efforts Program.

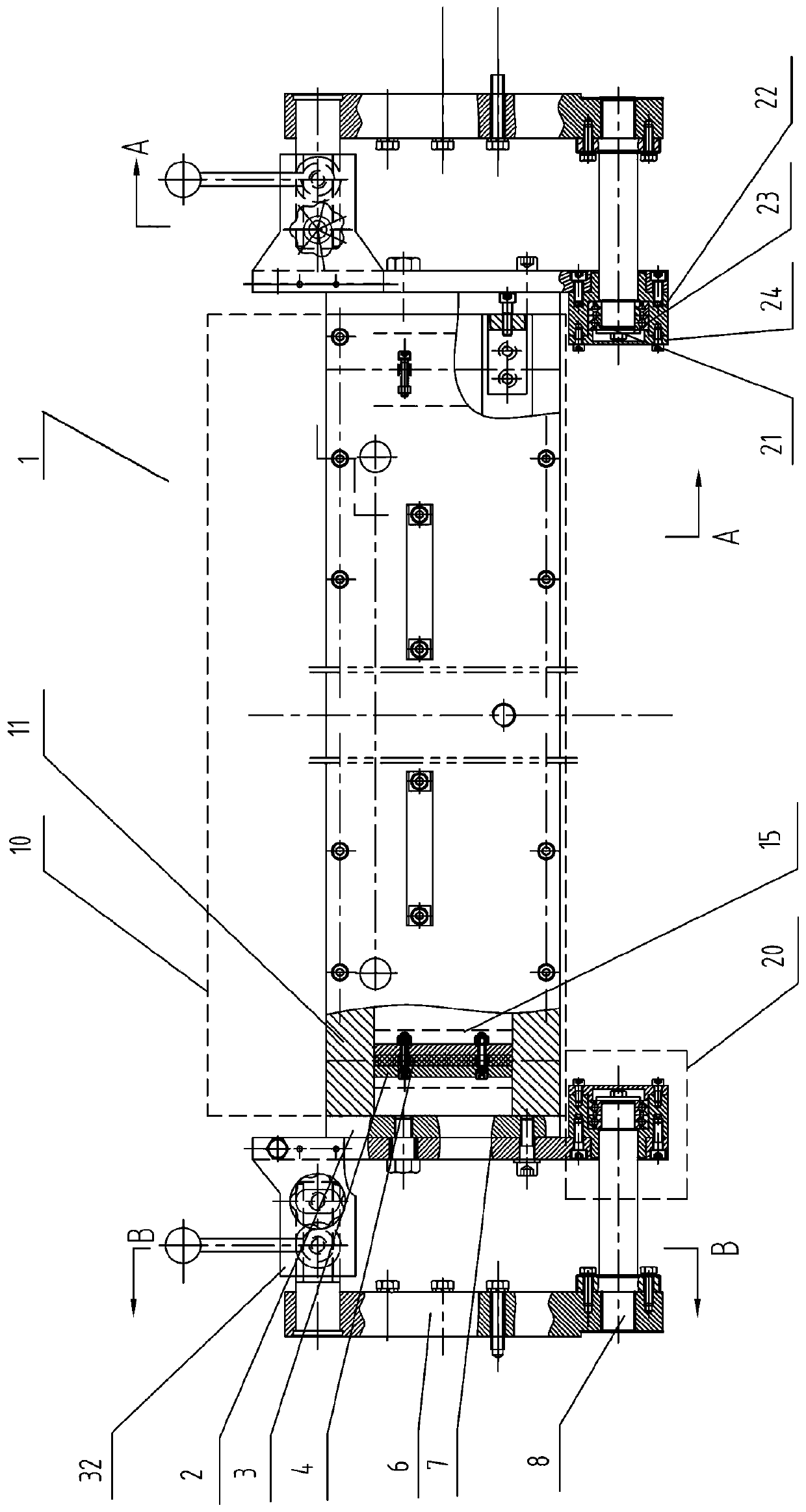

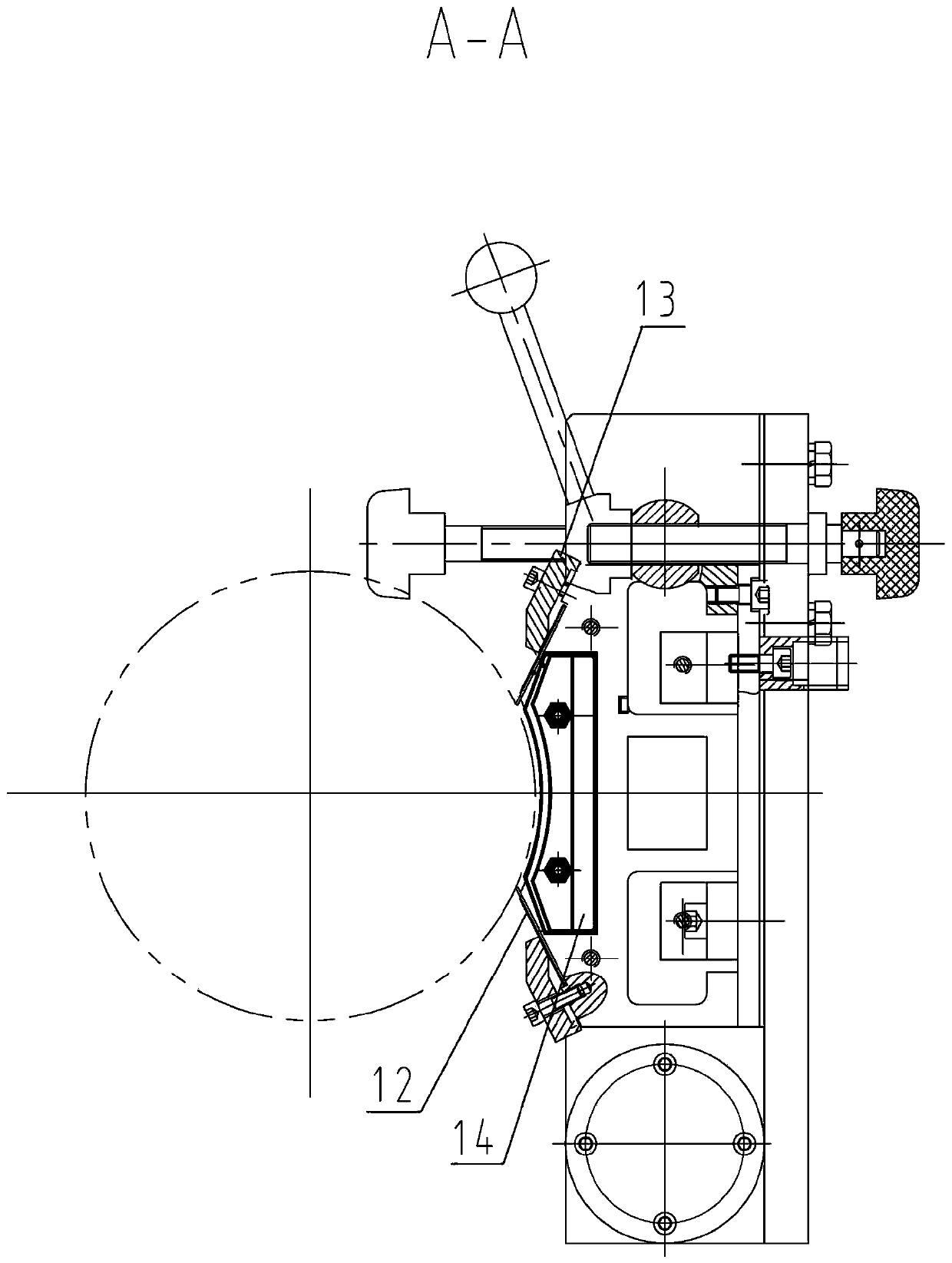

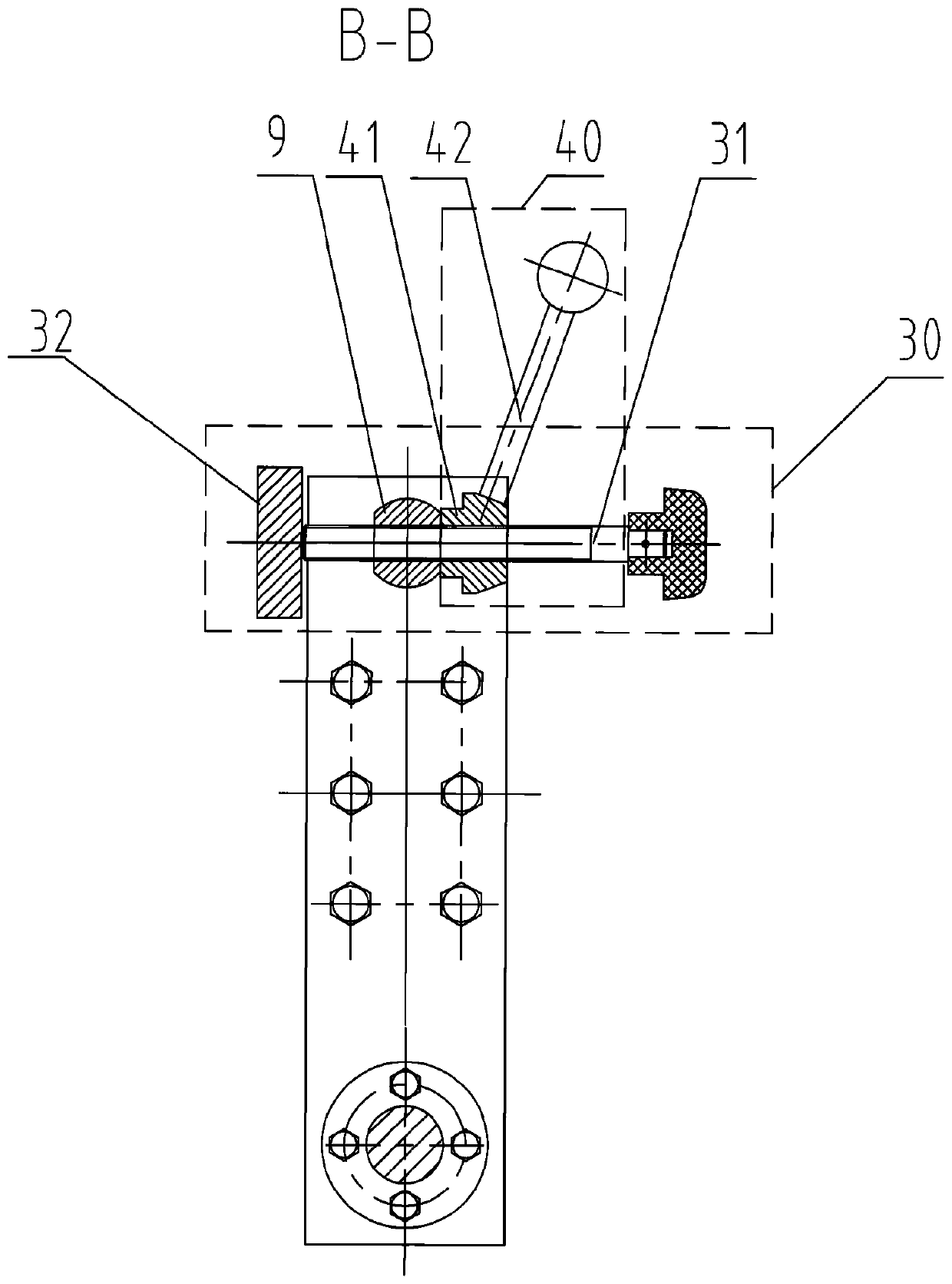

[0035] In this manual, refer to figure 1 , the longitudinal direction refers to the direction extending along the axial direction of the printing plate roll, and the transverse direction refers to the direction perpendicular to the longitudinal direction and located at figure 1 By a direction in the plane of the paper, a lateral direction refers to a direction perpendicular to the longitudinal direction and the transverse direction. In addition, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com