Device for producing polyalkylene polyamine-type chelating resin

A polyalkylene polyamine type, chelating resin technology, applied in the field of compound synthesis devices, can solve the problems of complex production devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

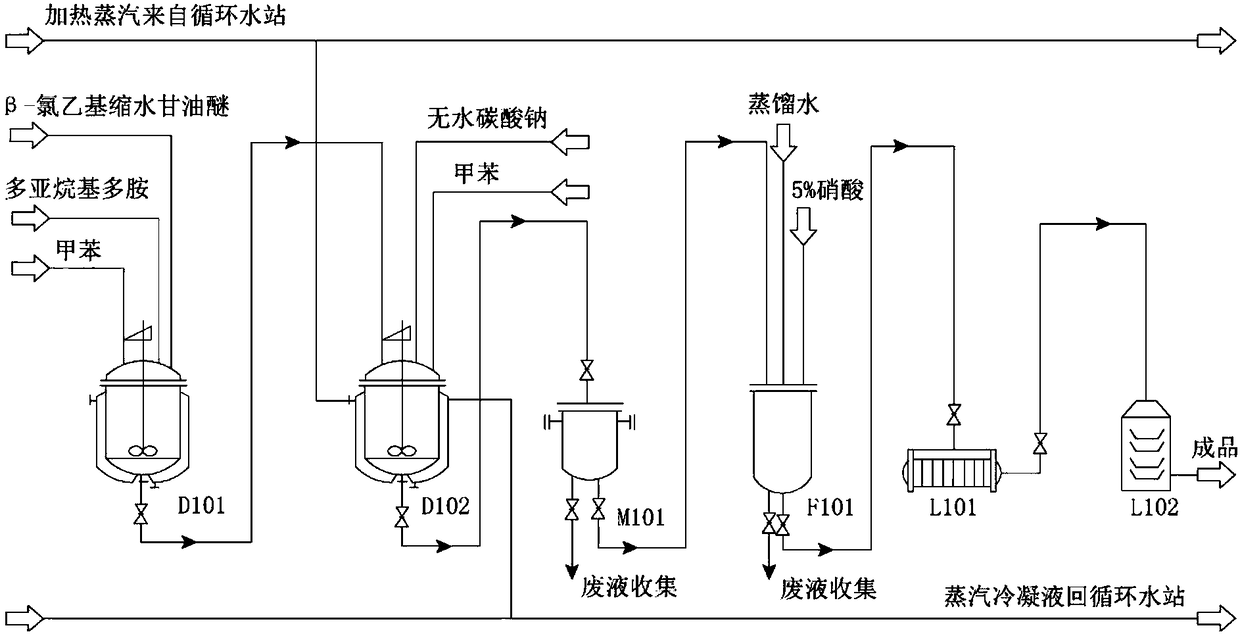

Image

Examples

example 1

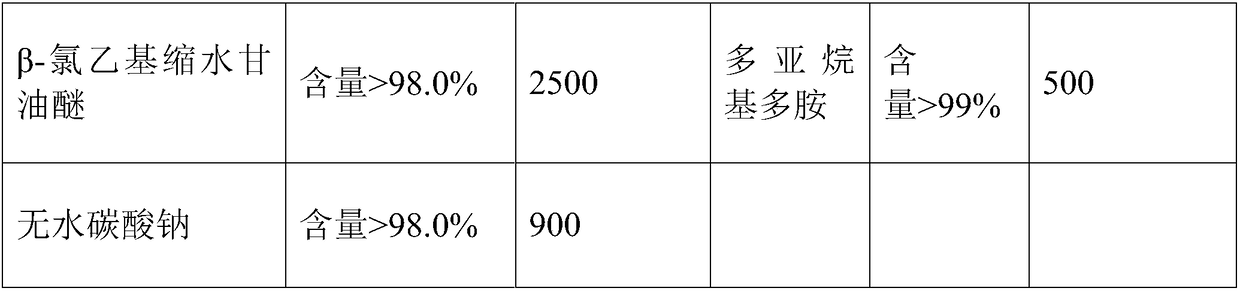

[0008] Production raw materials and dosage

[0009]

[0010] The production equipment of polyalkylene polyamine type chelating resin mainly includes: batching kettle (D101), reaction kettle (D102), filter (M101), washing tank (F101), suction filter (L101), dryer ( L102), wherein, the reaction kettle (D102) is connected with the batching kettle (D101) and the filter (M101) respectively, and the suction filter (L101) is connected with the washing tank (F101) and the drier (L102) respectively, wherein the batching The kettle (D101) has a nominal volume of 1300L, the diameter of the outer pot of the reaction kettle (D102) is 1200mm, and the cylinder diameter of the washing tank (F101) is 700mm.

[0011] The production device of polyalkylene polyamine type chelating resin, the production process is: add the homopolymer of β-chloroethyl glycidyl ether, anhydrous polyalkylene polyamine and toluene into the batching kettle D101, mix well Finally, put it into the reaction kettle D1...

example 2

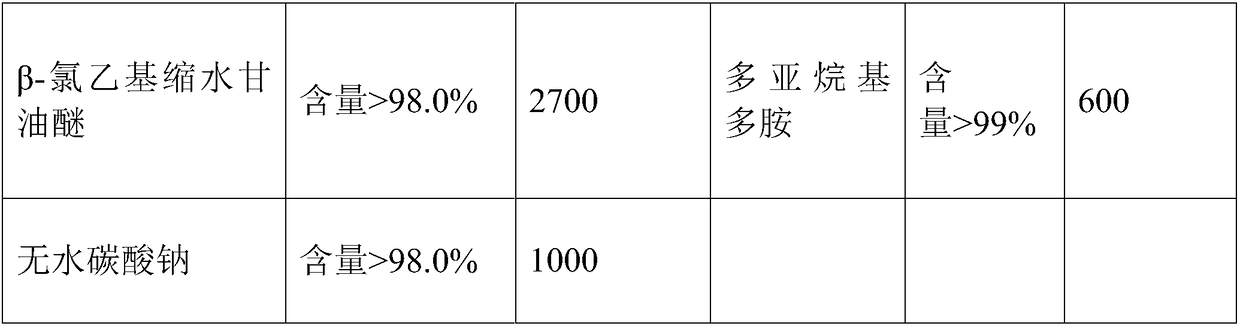

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of polyalkylene polyamine type chelating resin mainly includes: batching kettle (D101), reaction kettle (D102), filter (M101), washing tank (F101), suction filter (L101), dryer ( L102), wherein, the reaction kettle (D102) is connected with the batching kettle (D101) and the filter (M101) respectively, and the suction filter (L101) is connected with the washing tank (F101) and the drier (L102) respectively, wherein the batching The kettle (D101) has a nominal volume of 1400L, the diameter of the outer pot of the reaction kettle (D102) is 1300mm, and the cylinder diameter of the washing tank (F101) is 750mm.

[0018] The production device of polyalkylene polyamine type chelating resin, the production process is: add the homopolymer of β-chloroethyl glycidyl ether, anhydrous polyalkylene polyamine and toluene into the batching kettle D101, mix well Finally, put it into the reaction kettle D1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com