Grouting treatment method for underlying coal mine gob area along railway

A goaf and grouting technology, applied in mining equipment, earth-moving drilling, filling and other directions, can solve the problems of lack of systematic results, mature theory and engineering design system, lack of norms and regulations, etc. Overall performance, reducing hidden dangers of geological disasters, and ensuring social harmony and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

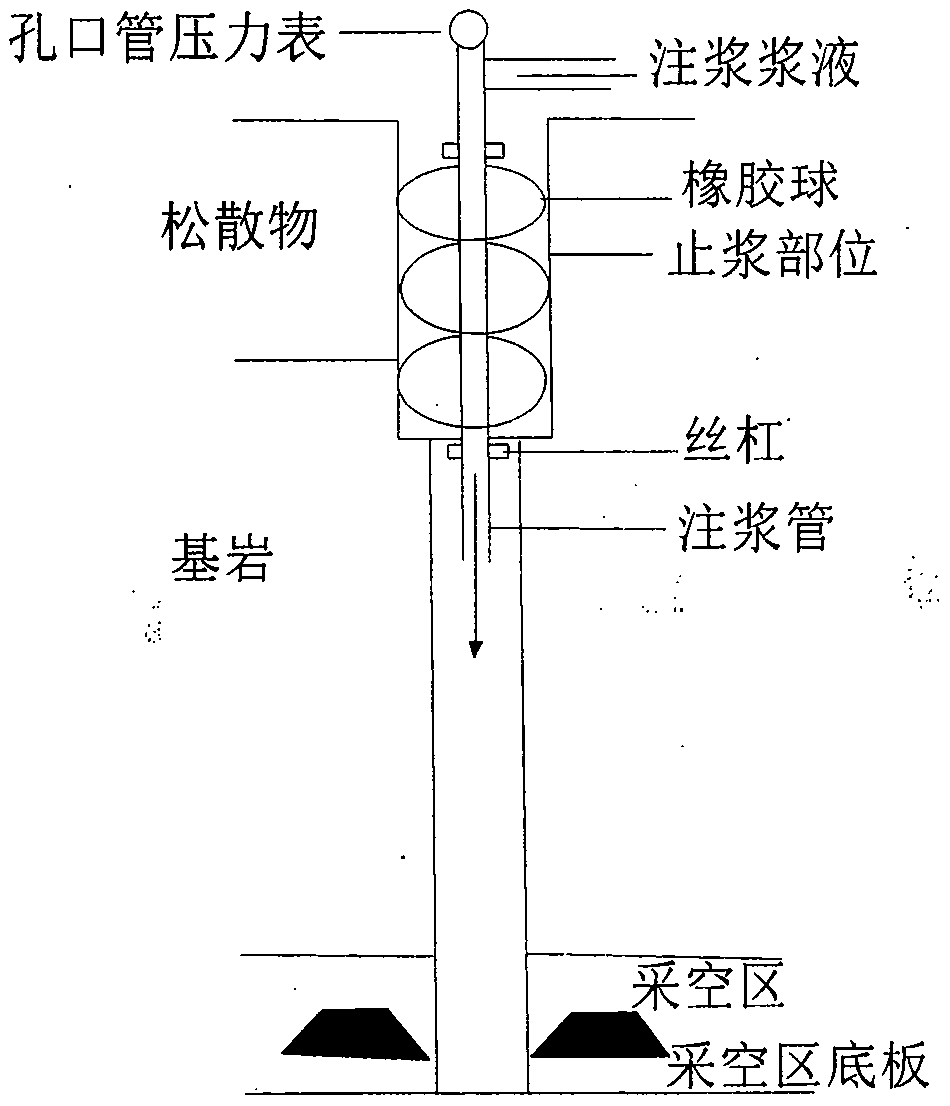

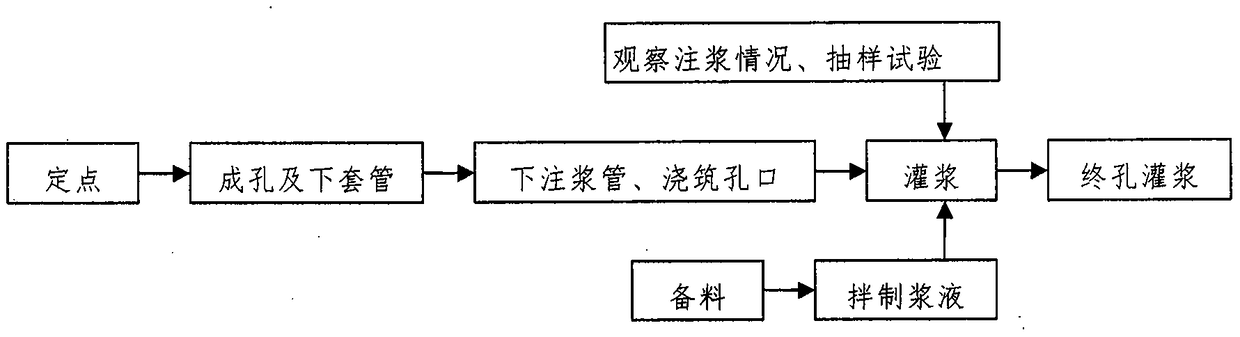

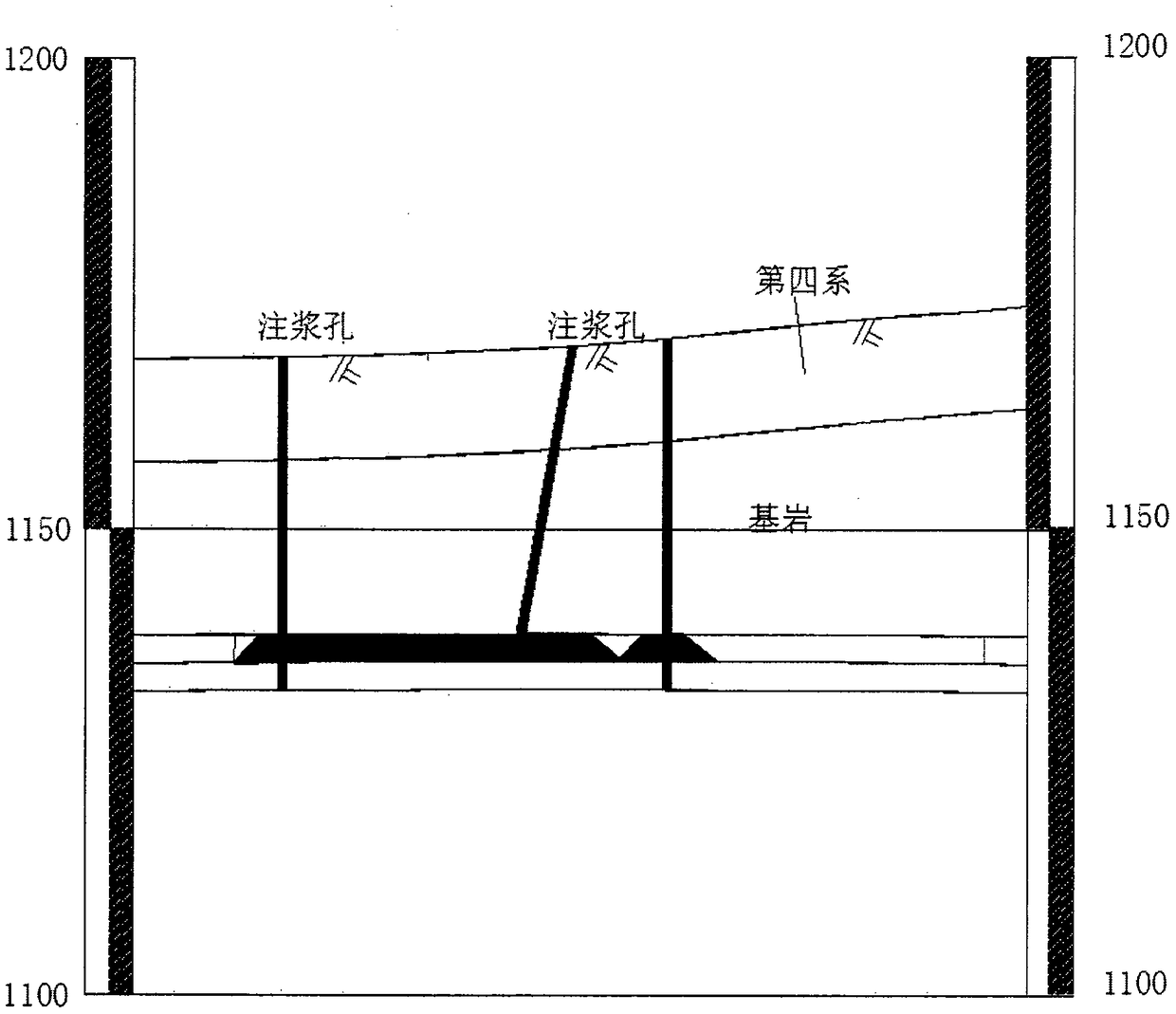

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0064] The grouting equipment and tools used in the following examples need to meet the following requirements:

[0065] (1) Drilling rig: The drilling rig should be selected according to the requirements of the goaf's rock formation structure, lithology, grouting hole or curtain hole structure, and slurry stop technology. Percussion drilling rigs or drilling tools without coring should not be used. Rotary drilling rigs and carbide drills with core pipes should be used.

[0066] (2) The speed and pulping capacity of the mixer should be compatible with the engineering quantity, type of slurry and performance of the grouting pump, and the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com