Aluminum-lithium alloy two-stage continuous aging treatment method

An aluminum-lithium alloy and aging treatment technology, which is applied in the field of aluminum alloy processing, can solve problems such as difficult to control, slow temperature change rate, and reduced atomic diffusion rate, and achieve the effects of solving production efficiency problems, reducing energy consumption, and shortening aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this example, an aluminum-lithium alloy sheet prepared with the same composition and production process as Comparative Example 1 was used, and the solution quenching and pre-deformation processes were also the same as Comparative Example 1.

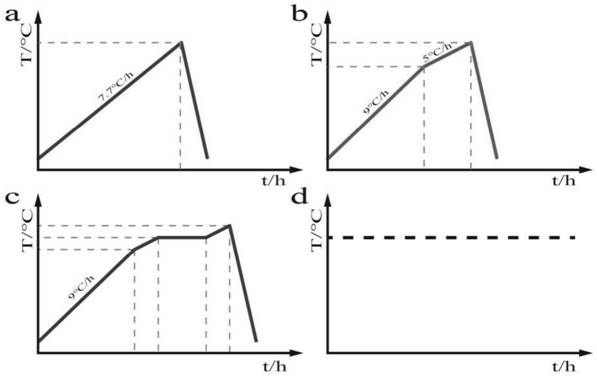

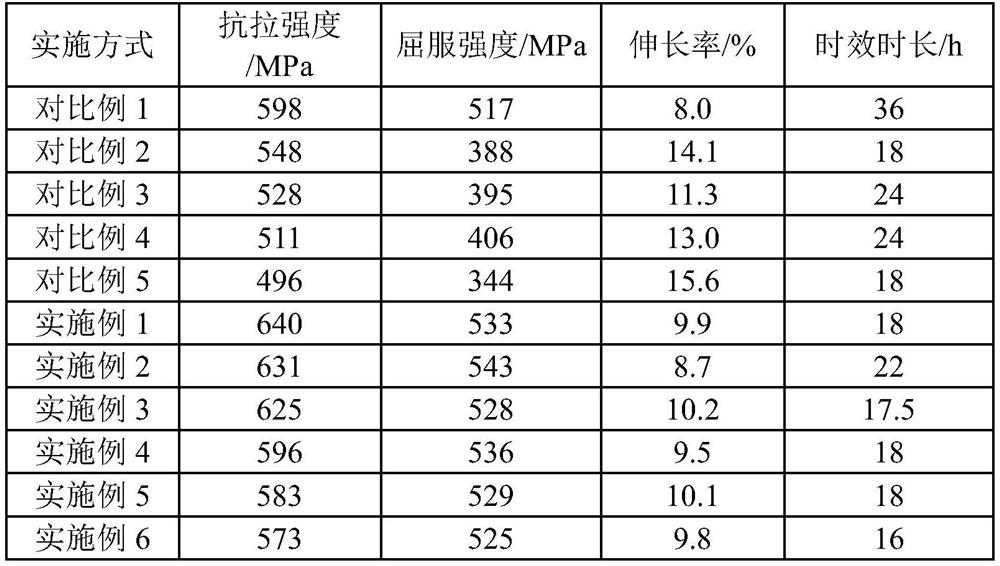

[0052] Aging process: Put the sample into a resistance furnace heated to 22°C, then raise the temperature to 130°C after 12 hours, and the heating rate during the period is 9°C / h; °C / h, the cooling method is furnace cooling, and the cooling rate with the furnace is <50 °C / h. The final mechanical properties of the obtained materials are shown in Table 1.

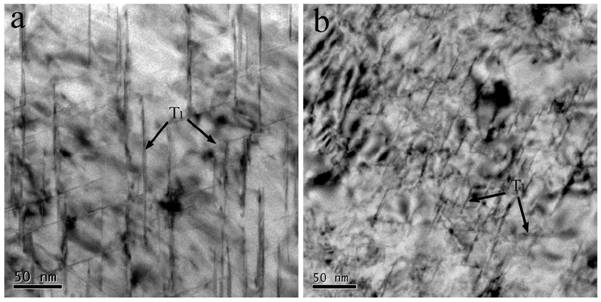

[0053] figure 2 b is the transmission electron microscope microstructure picture of this comparative example.

Embodiment 2

[0055] In this example, an aluminum-lithium alloy sheet prepared with the same composition and production process as Comparative Example 1 was used. The sample was subjected to solution treatment by gradually increasing the temperature, and the solution was carried out in a salt bath. After the solution treatment, it was quickly taken out and cooled to room temperature. The quenched samples were subjected to 5% cold rolling pre-deformation.

[0056] Aging process: Put the sample into a resistance furnace heated to 21°C, then raise the temperature to 140°C after 17 hours, and the heating rate during the period is 7°C / h; °C / h, the cooling method is furnace cooling, and the cooling rate with the furnace is <50 °C / h. The final mechanical properties of the obtained materials are shown in Table 1.

Embodiment 3

[0058] In this example, an aluminum-lithium alloy sheet prepared with the same composition and production process as Comparative Example 1 was used. The sample was subjected to solution treatment by gradually increasing the temperature, and the solution was carried out in a salt bath. After the solution treatment, it was quickly taken out and cooled to room temperature. The quenched samples were subjected to 5% cold rolling pre-deformation.

[0059] Aging process: Put the sample into a resistance furnace heated to 0°C, then raise the temperature to 120°C after 10 hours, and the heating rate during the period is 12°C / h; then raise the temperature from 120°C to 150°C over 7.5 hours, during the heating rate is 4°C / h, the cooling method is furnace cooling, and the cooling rate with the furnace is <50°C / h. The final mechanical properties of the obtained materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com