3D printing technology based artificial initial cracks containing rock-like specimen preparation method

A 3D printing, rock sample technology, applied in the fields of water conservancy and hydropower engineering, civil engineering, can solve problems such as difficulty in making built-in cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for preparing a rock sample capable of producing tiny and closed joints of the present invention will be described in detail below in conjunction with the examples.

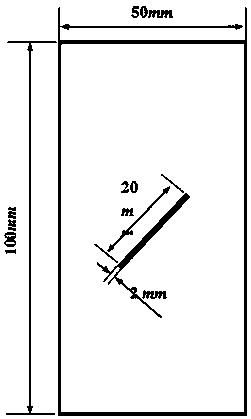

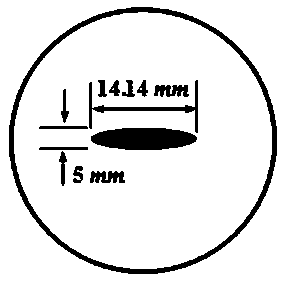

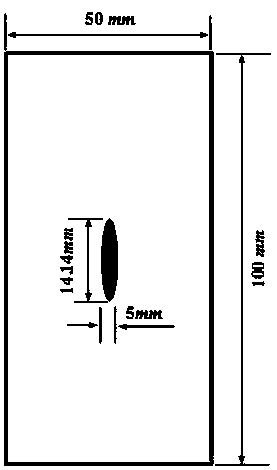

[0018] figure 1 , 2 , 3 show a closed fracture diagram of an ellipsoid with an inclination angle of 45°C. The preparation of a closed crack with an inclination angle of 45°C and an ellipsoid includes the following steps:

[0019] (1) Determine the size of the geometric model. The size of the sample is Φ50mm×100mm, the number of cracks n=1, the inclination angle α=45°C, the major axis of the elliptical crack is 20mm, the minor axis is 5mm; and the crack width is 2mm. The crack is located at the center of the sample.

[0020] (2) According to the determined model size, use the computer to establish the corresponding three-dimensional digital space model.

[0021] (3) Input the three-dimensional digital space model into the 3D printing device with one-time molding, and prepare the photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com