Performance evaluation device for barite blocking remover and evaluation method thereof

An evaluation device and barite technology, applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of not being able to truly reflect the plugging performance and the limited guiding role of barite plugging agents, etc., to achieve The effect of dosage optimization and enhanced awareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

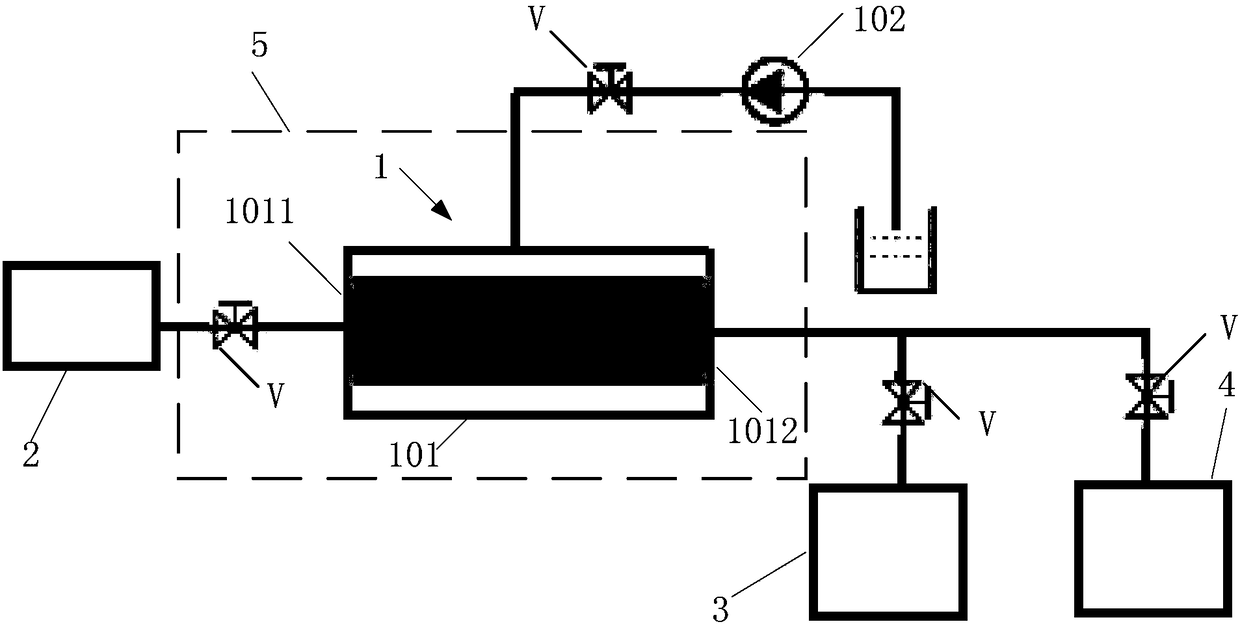

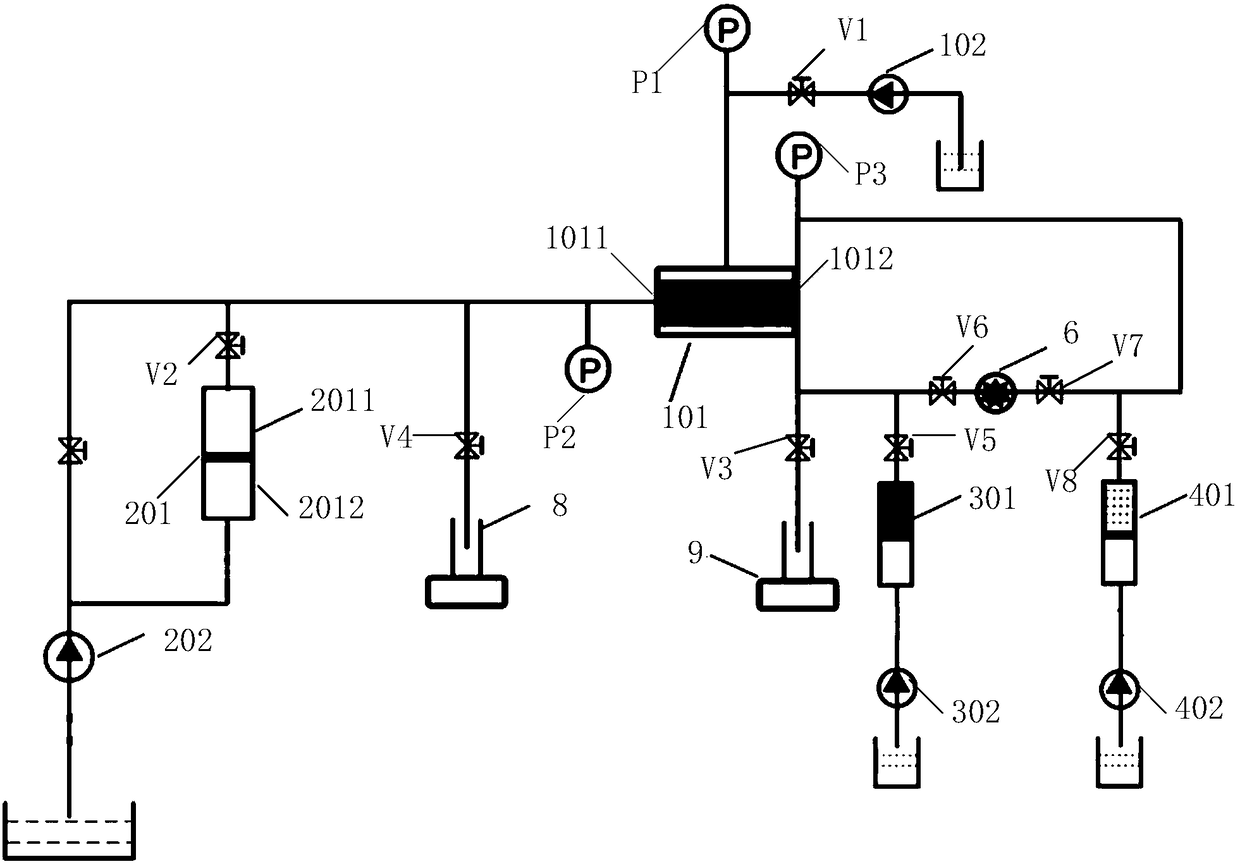

[0113] Such as figure 2 As shown, the simulation evaluates the plugging removal performance of the barite plugging agent after the reservoir of the oil well is damaged by barite drilling fluid. Among them, the diameter of the core is 25.4-50.8 mm, and the length is 30-100 mm.

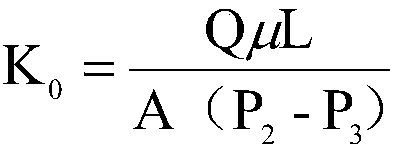

[0114] (1) Connect the experimental process, cover the core with an annular rubber sleeve, and put it into the core holder, where the right end of the core must be completely parallel to the right end of the core holder, so as to simulate the barite drilling fluid and the reservoir The process of contact injury, such as figure 2 As shown, after the core is placed, the first valve V1 is opened, the first pump 102 applies confining pressure to the core in the holder 101, the pressure read from the first pressure sensor P1 is the confining pressure, and the confining pressure should be higher than that of barite During the drilling fluid circulation damage process, the pressure of the barite plugging a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com