Method of measuring friction coefficient by using thermal analog machine

A friction coefficient and thermal simulation technology, applied in the field of high temperature friction coefficient, can solve the problems of poor measurement accuracy, only under 75℃ or normal temperature, and small measurement range, so as to improve measurement accuracy, avoid errors and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] 1) Select the compression sample:

[0064] Select JIS-SUJ 2, the sample size is Φ8*12mm.

[0065] 2) Selection and determination of deformation conditions:

[0066] Deformation temperature: 1000°C;

[0067] Strain rate: 0.1 / s;

[0068] True strain: 0.5.

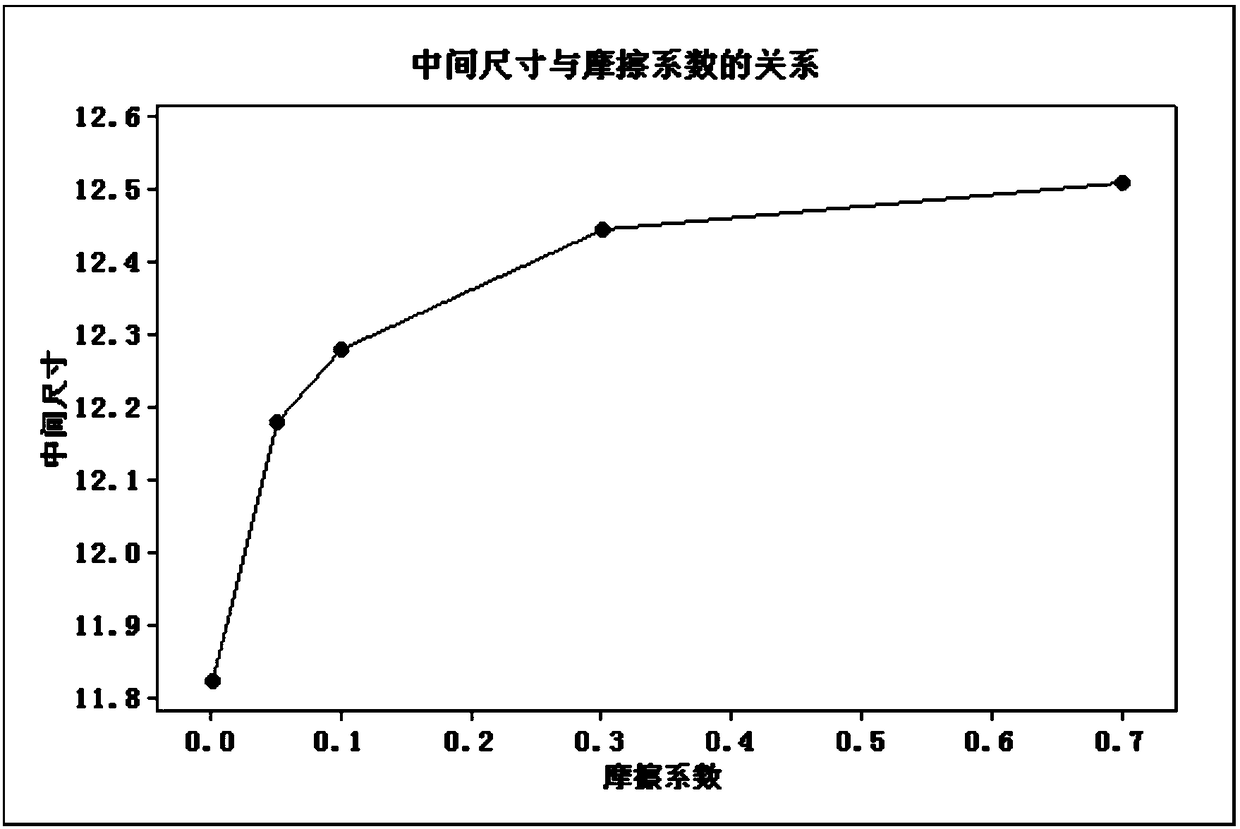

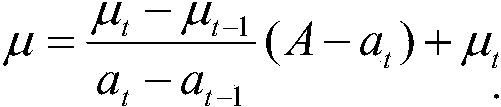

[0069] 3) Calculation of the reference curve for the relationship between the theoretical friction coefficient and the middle diameter:

[0070] Using numerical simulation software, calculate the theoretical friction coefficient as 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6,

[0071] The corresponding middle diameter size at 0.7 is shown in Table 1:

[0072]

[0073] Table 1 The diameter of the middle part of the model corresponding to the theoretical friction coefficient

[0074] 4) Conduct thermal simulation compression experiments and measure the size of the deformed sample:

[0075] Add the lubricating material to be tested, under its lubricating conditions, use the compression sample selected in the above step 1) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com