Steam-curing device for manufacturing fabricated structure and mounting method

A prefabricated, steam-cured technology, applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of rapid increase in concrete strength, energy saving, water saving, etc., to speed up factory production, improve production efficiency and economic benefits, and speed up turnover The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A prefabricated concrete structure workshop adopts a prefabricated prefabricated structure steam curing device to steam cure concrete prefabricated components. The concrete prefabricated components can reach more than 75% of the structural design strength after steaming for 5-7 hours, which speeds up the turnover of equipment and materials. Increased production efficiency.

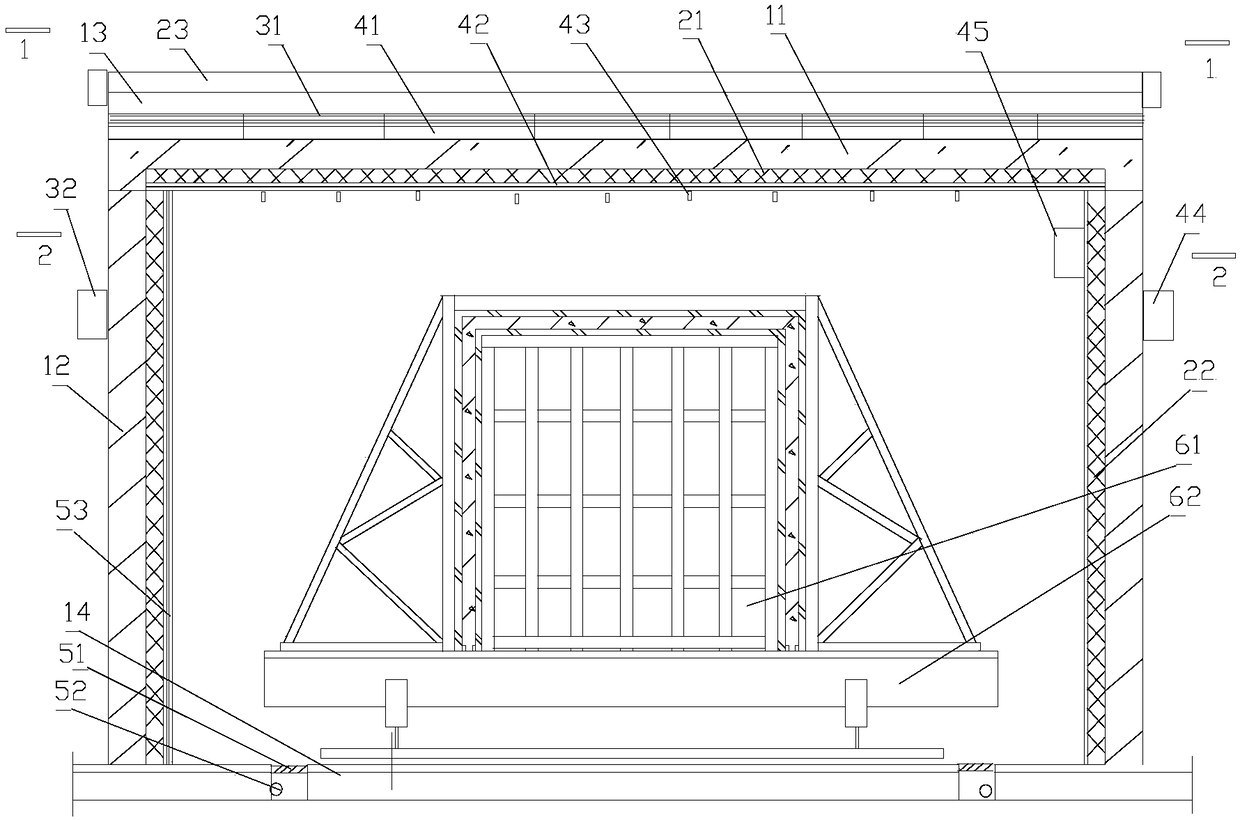

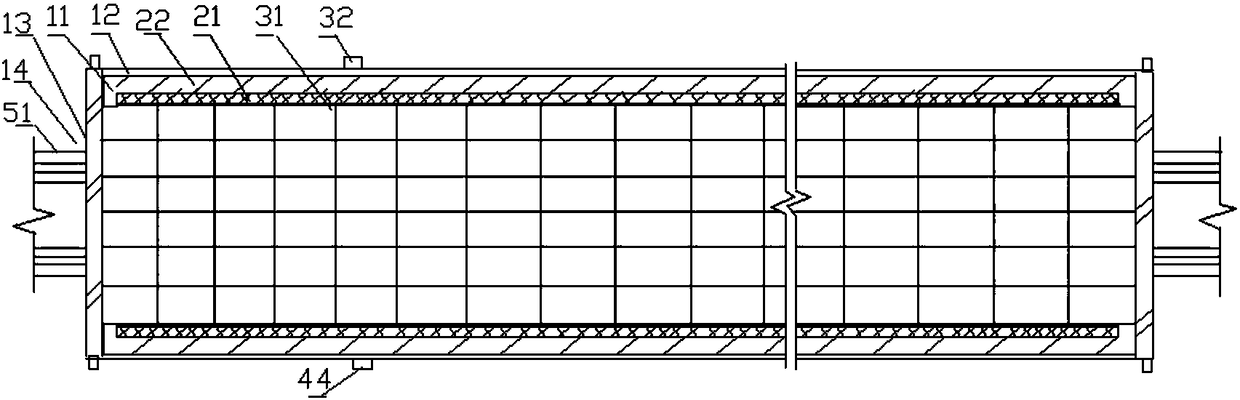

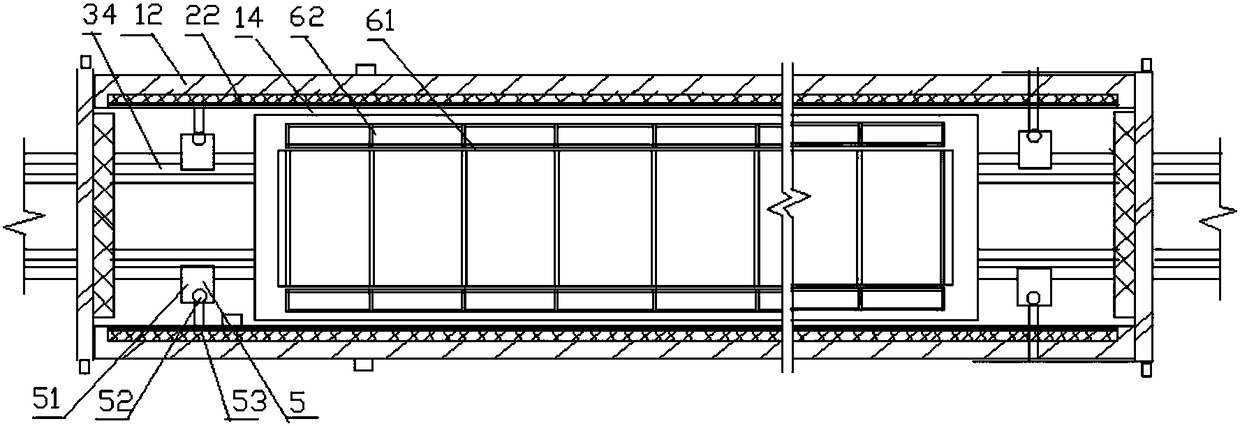

[0035] The steam curing device for making an assembled structure is composed of a steam curing room structure 1, a steam curing room insulation layer 2, an energy facility 3, a temperature and humidity control facility 4, a water recovery facility 5 and a structural mobile facility 6; among them, the steam curing room Structure 1 is composed of a steaming room roof structure 11, a steaming room wall structure 12, a steaming room rolling door 13 and a steaming room ground structure 14; a steaming room insulation layer 2 is composed of a steaming room roof insulation layer 21, a steaming room Room wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com