Method for manufacturing grooved isolated cabin of ship

A manufacturing method and trough-shaped technology, which are applied in shipbuilding, ship parts, ships, etc., can solve the problems that affect the smooth progress, the tire frame takes up a large space, and the production is complicated, so as to achieve the improvement of the utilization turnover rate, the improvement of manufacturing precision, and the improvement of The effect of making speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

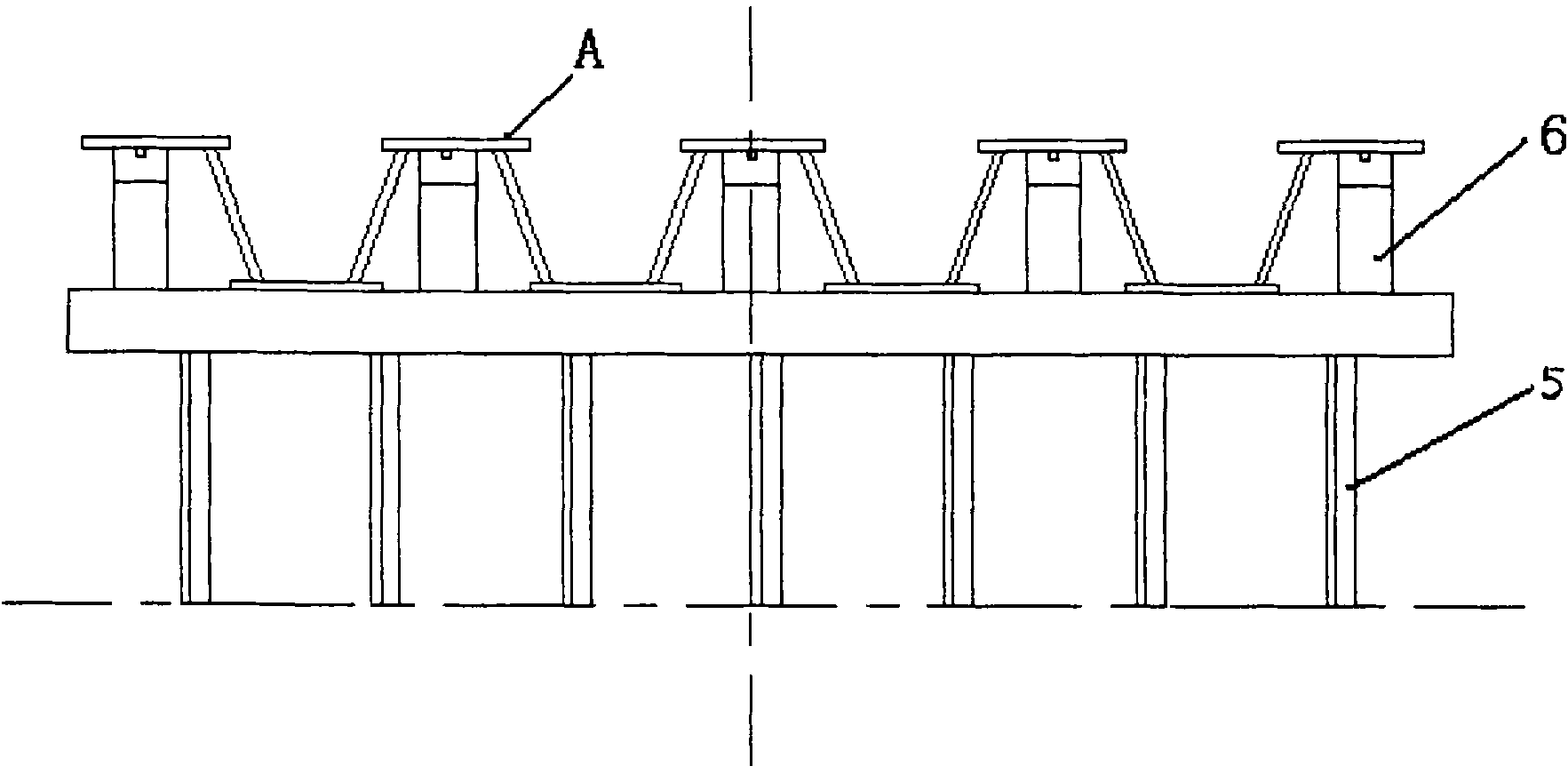

[0029] The manufacturing method of the ship's grooved compartment of the present invention will be specifically described below by taking the manufacture of the grooved compartment of a 745,000-ton bulk carrier as an example.

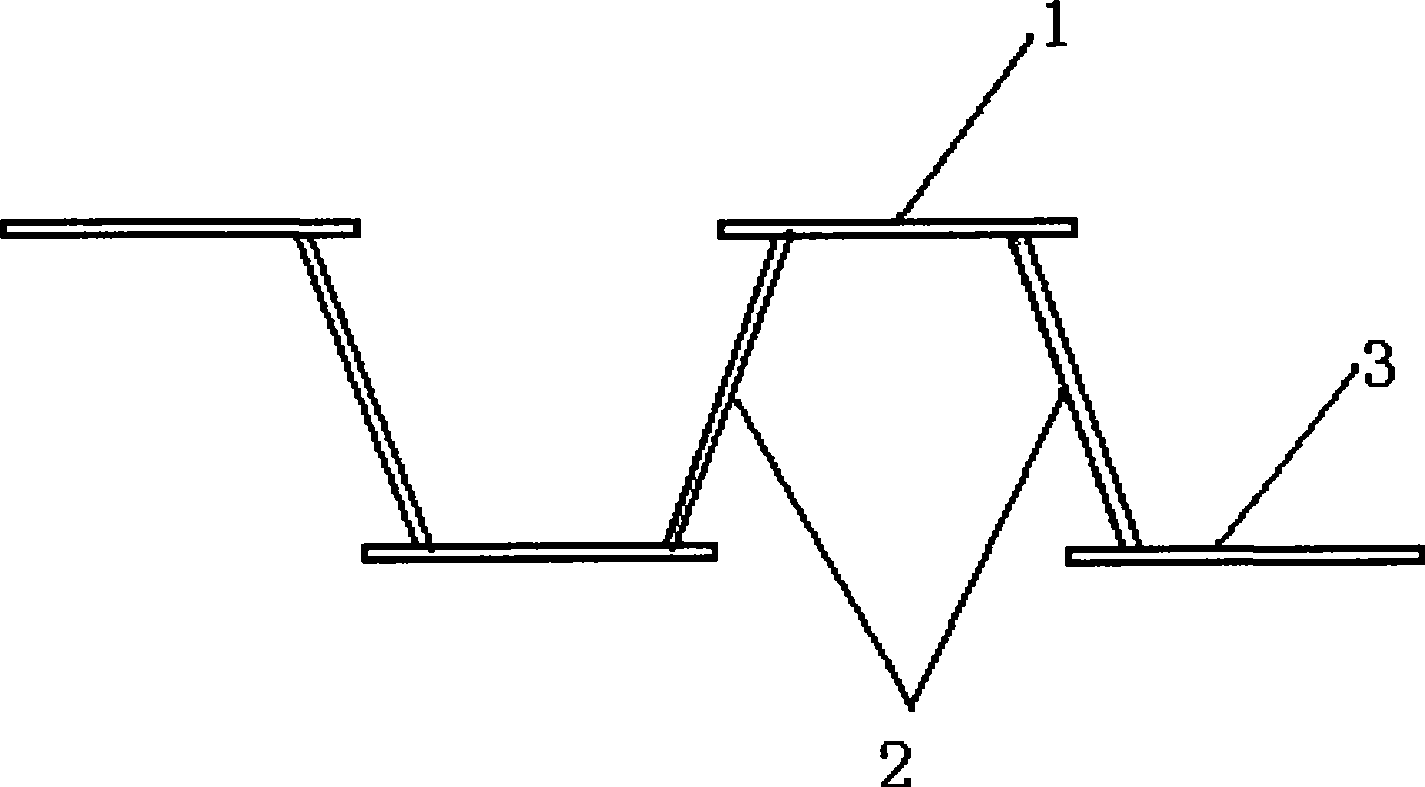

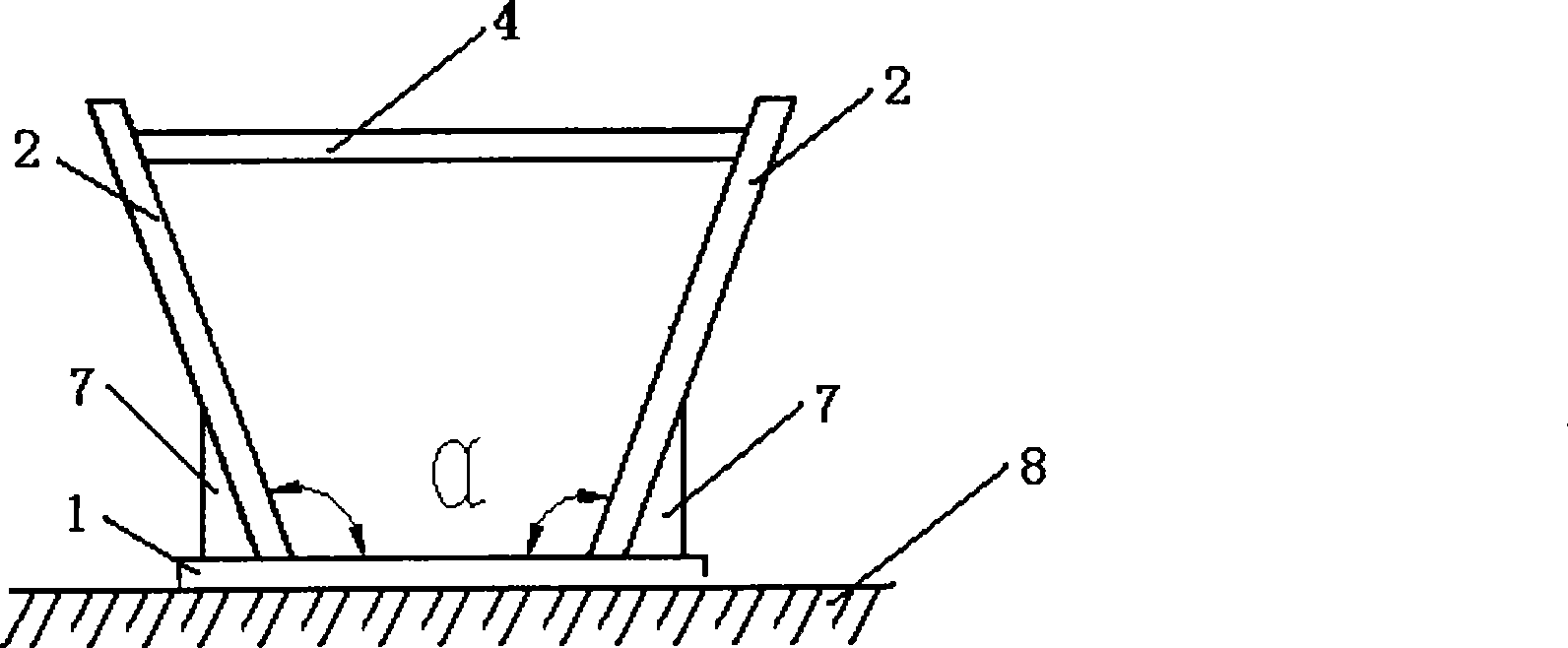

[0030] ① Prepare the component parts and auxiliary parts of the trough compartment, where the component parts include the first deck 1, the second deck 2 and the third deck 3, and the auxiliary parts include the reinforcement plate 4 and the angle template 7;

[0031] ②Draw positioning lines at the connection positions of each first deck 1, second deck 2 and third deck 3, that is, draw out the two ends of the first deck 1 and third deck 3 according to the distribution of the drawings The connection position with the second deck 2;

[0032] ③ Place a first deck 1 on the platform, then place one end of the two second decks 2 on the line drawn on the first deck 1, and tilt at a certain angle a=120°, so that the two second decks 2 The second deck 2 forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com