Printing method of polyester blended fabrics

A technology of blended fabrics and printing methods, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor color fastness, easy fading of fabrics, etc., and achieve good printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

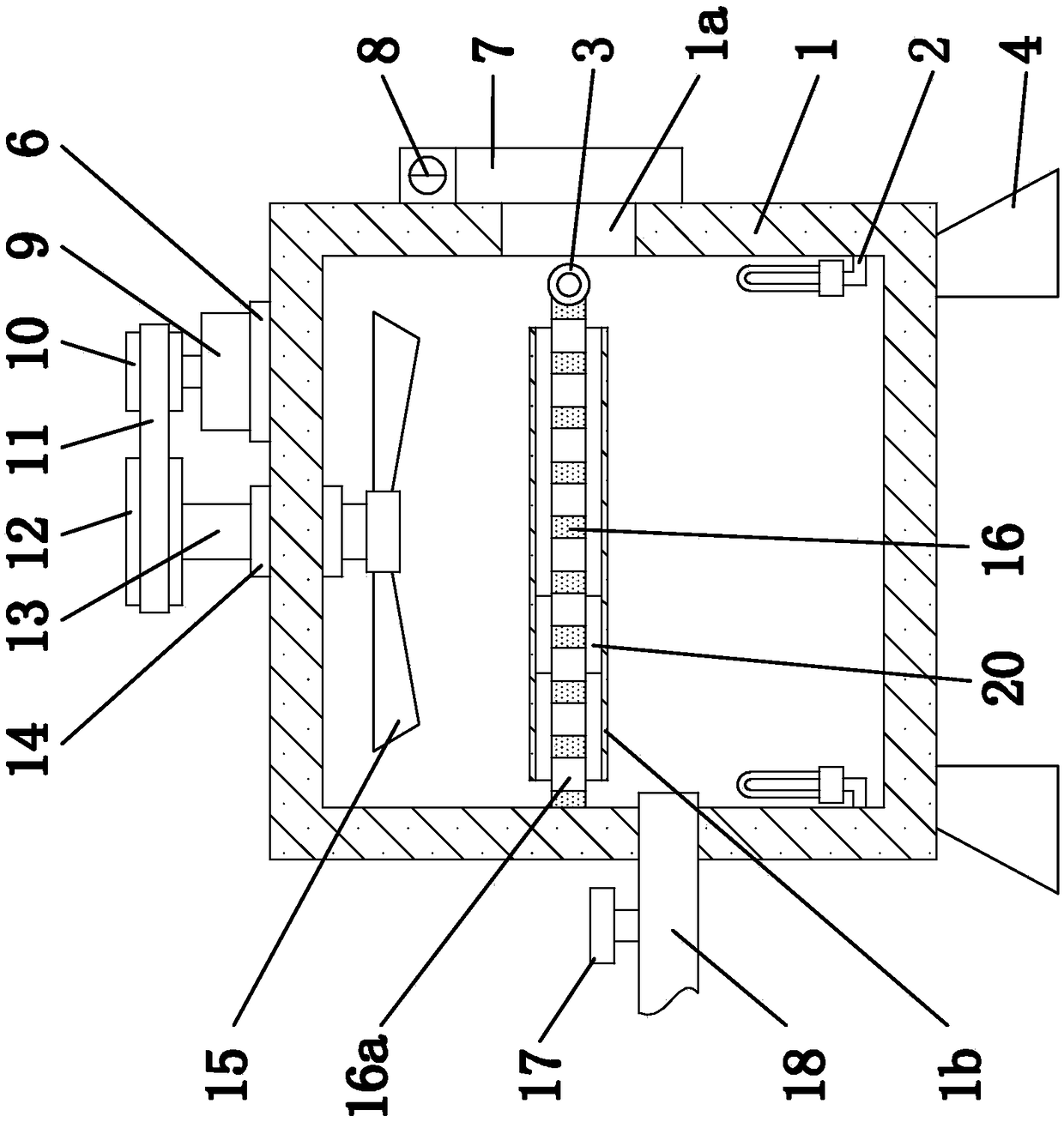

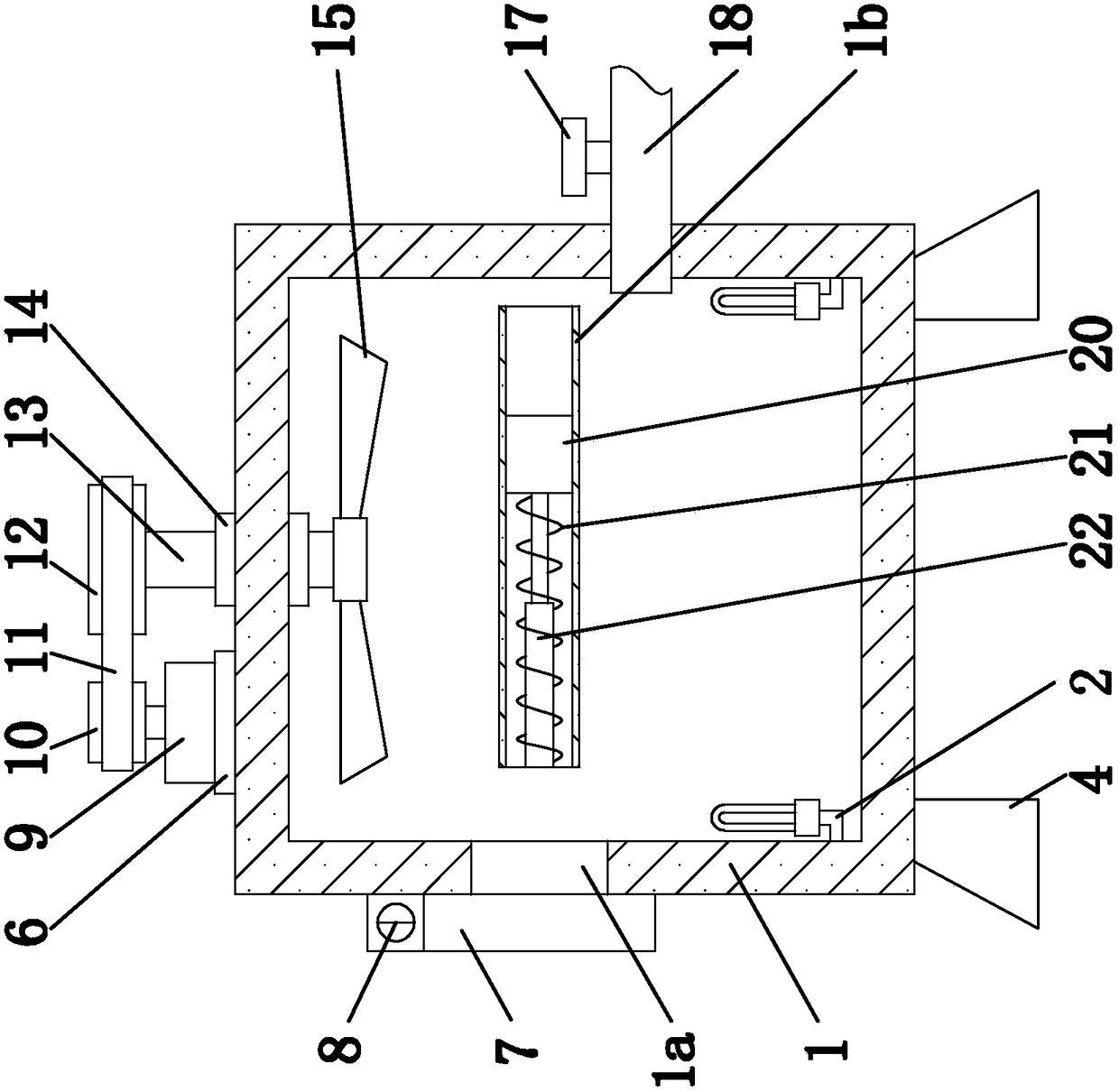

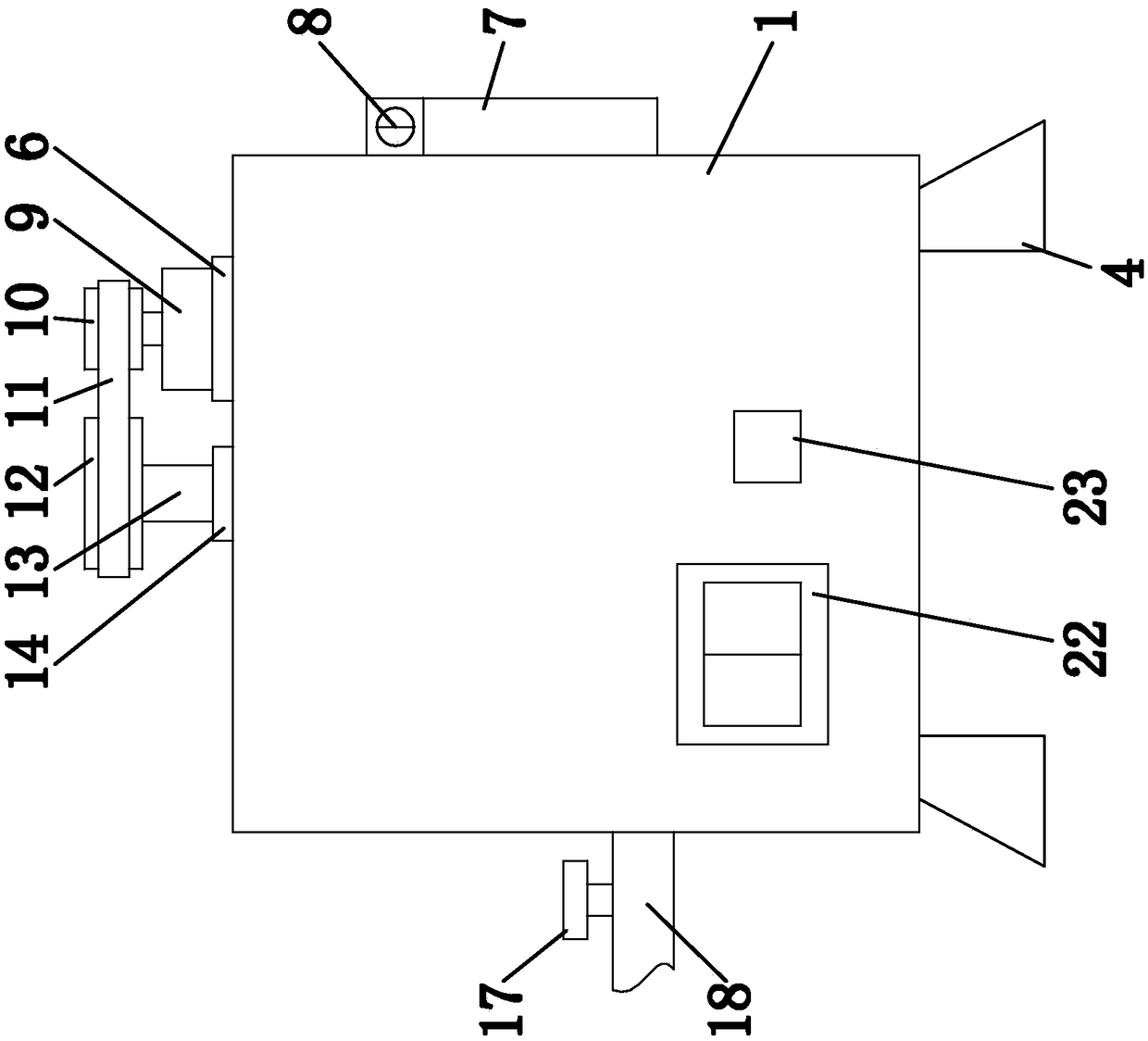

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0037] The printing method of this polyester blended fabric comprises the steps:

[0038] a, pretreatment: remove the impurities on the surface of the polyester blended fabric by a hot air blower, and preheat it. The temperature of the hot air blower is 28-36 ° C; Impurities are removed and preheated, the temperature of the hot air blower is 30°C;

[0039] b. Printing treatment: the polyester blended fabric is printed by a liquid jet printing machine, and the printing temperature is 45-55°C; in this embodiment, the polyester blended fabric is printed by a liquid jet printing machine, and the printing temperature is 48°C ;

[0040]c. Color fixation treatment: put the printed polyester blended fabric into a steamer for steam fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com