Ultraviolet light source assembly, ultraviolet optical system and ultraviolet printing device

A technology for an ultraviolet light source and an optical system, which is applied in the fields of ultraviolet light source components, ultraviolet optical systems and ultraviolet printing devices, can solve the problems of difficult heat dissipation, high manufacturing and use costs, and low reliability, and achieves simplified structure and improved reliability. , The effect of reducing the difficulty of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

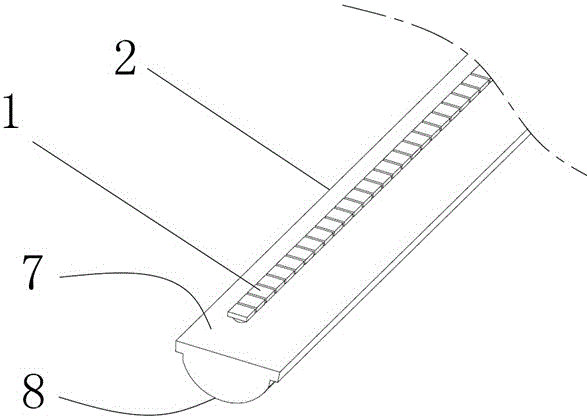

[0055] Embodiment 1: as figure 1 and 3 as shown,

[0056] An ultraviolet light source assembly, including several light sources 1 for emitting ultraviolet light, and also includes a light collection device 2, the light collection device 2 cooperates with the light source 1, so that each light source 1 emits all or part of the light After entering the light collecting device 2, the light collecting device 2 converges the light entering into a plane, and forms a continuous strip-shaped irradiation area 3 in the plane.

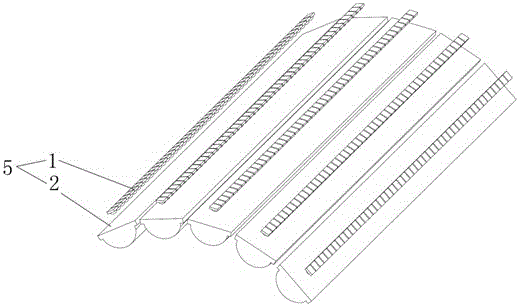

[0057] In the field of ultraviolet light application technology, for the traditional ultraviolet light source assembly 5, it is a plurality of light sources 1, in the state of free light, superimposed on a working surface for printing work, and the ultraviolet light source assembly 5 of the present application , using the light collection device 2 to collect and collect the light emitted by the light source 1, and form a continuous strip-shaped irradiation are...

Embodiment 2

[0061] Example 2, such as Figure 1-5 Shown:

[0062] Based on the structure of Embodiment 1, the light collecting device 2 is a lens. The lens is used as the light collection device 2 , the lens has good integrity, which further simplifies the structure, and the shape of each optical surface of the lens is well controlled, so that the light can be adjusted conveniently.

[0063] As an implementation manner, each of the light sources 1 is arranged in a straight line.

[0064] In the above-mentioned scheme of the present application, each light source 1 is arranged on the same straight line, so as to facilitate the formation of a straight-line irradiation area or a straight-line continuous linear light strip 4, and the length of the light strip 4 is the same as that of the printed article and the photoetched object. The length or width of the piece or the piece to be exposed is matched, so that when the light source assembly 5 moves relatively with the piece to be printed, th...

Embodiment 3

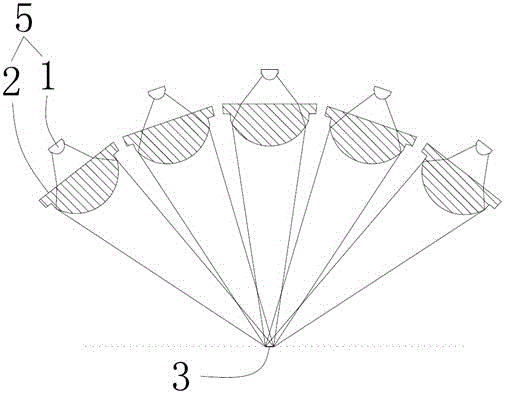

[0068] Example 3, such as Figure 6 , 8 and 9 as shown:

[0069] Based on the structure of Embodiment 1, the light collecting device 2 is a reflector.

[0070] As an embodiment, the reflector has a cylindrical reflective surface, each of the light sources 1 is arranged in the reflector, and the reflector gathers the light irradiated thereon and reflects it to the A strip-shaped irradiation area 3 or a continuous linear light strip 4 .

[0071] In this embodiment, the light collection device 2 can also use a reflector. When a reflector is used, the reflective surface of the reflector collects and gathers the light emitted by the light source 1. In this way, it also forms a strip with higher energy intensity as described above. Irradiate the area 3 or the continuous linear light strip 4, so that fewer light sources 1 can be used;

[0072] When the reflector structure is adopted, the light source 1 is located in the reflector, so that, on the one hand, all the light emitted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com