Connecting method of non-supporting-type composite floor slab and PEC shear wall

A technology of superimposed floor slabs and connection methods, applied to floors, walls, building components, etc., can solve the problems of high assembly rate, difficulty in threading reinforcement, fast construction speed of prefabricated steel structures, etc., to achieve improved stability, simple and efficient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

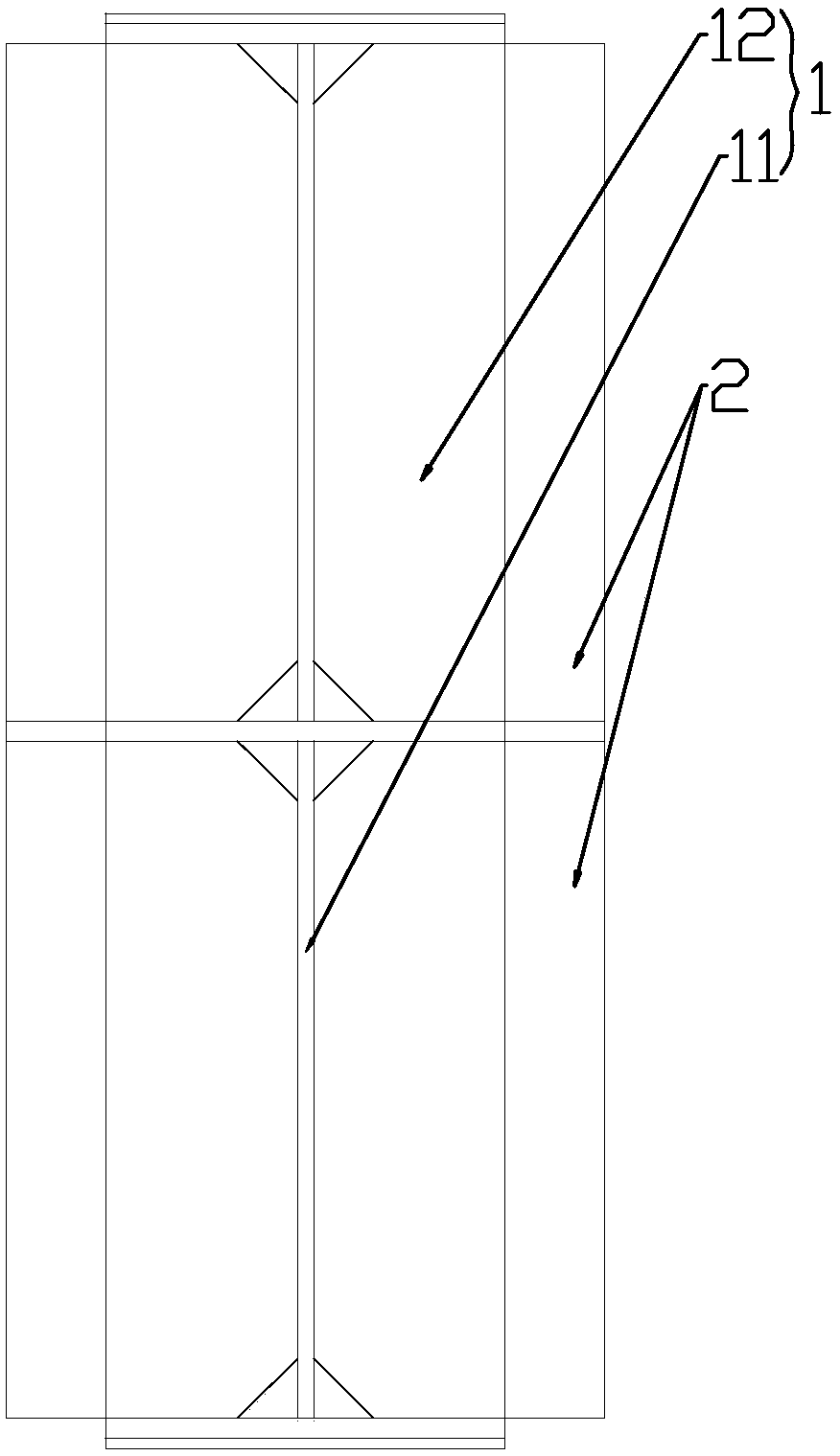

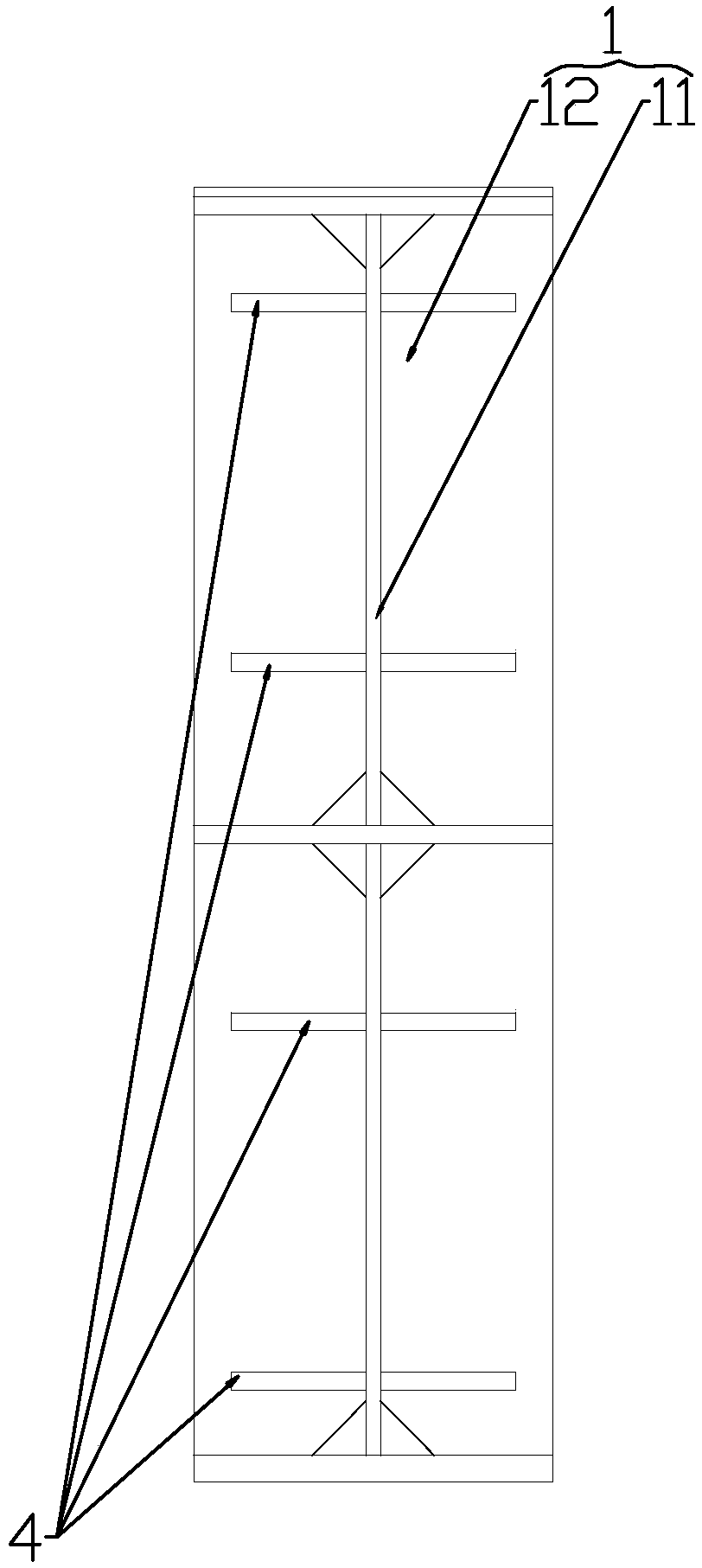

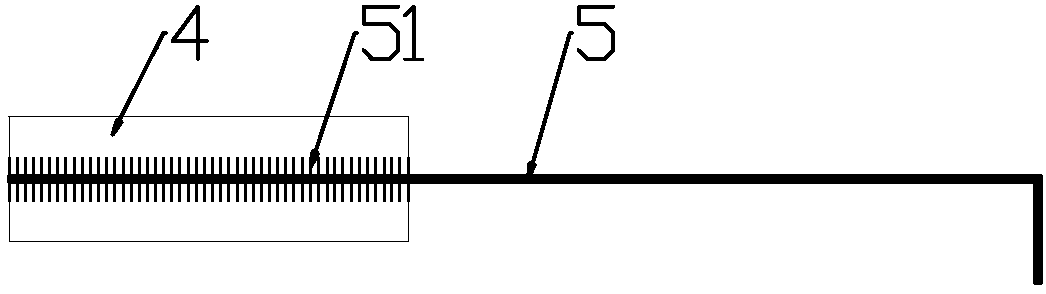

[0029] In this embodiment, a connection method between an unsupported laminated floor slab and a PEC shear wall combines figure 1 with figure 2 , the floor 3 and the PEC shear wall 1 are connected by several connectors 4, and the PEC shear wall 1 is composed of a steel skeleton 11 and a concrete body 12 formed by externally filled concrete. image 3 with Figure 4 ,, the connecting piece 4 is fixed on the PEC shear wall 1, the supporting negative rib 5 is fixed on the connecting piece 4, the supporting negative rib 5 extends into the floor 3, and the distance between adjacent connecting plates 4 is the same as the supporting negative rib Rib 5 is equally spaced.

[0030] In order to achieve more effects, the above scheme can also be added in the following way:

[0031] The PEC shear wall 1 is composed of a steel skeleton 11 formed by connecting a plurality of T-shaped steels in a straight line, and a concrete body 12 filled outside the steel skeleton. More preferably, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com