Tail gas aftertreatment box with tail gas treatment elements arranged side by side

An exhaust gas post-treatment and exhaust gas technology, which is applied in exhaust treatment, exhaust devices, engine components, etc., can solve the problems of difficult layout of volume components, limited space, and increased volume of the treatment box, so as to improve the mixing uniformity and improve the Conversion rate, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

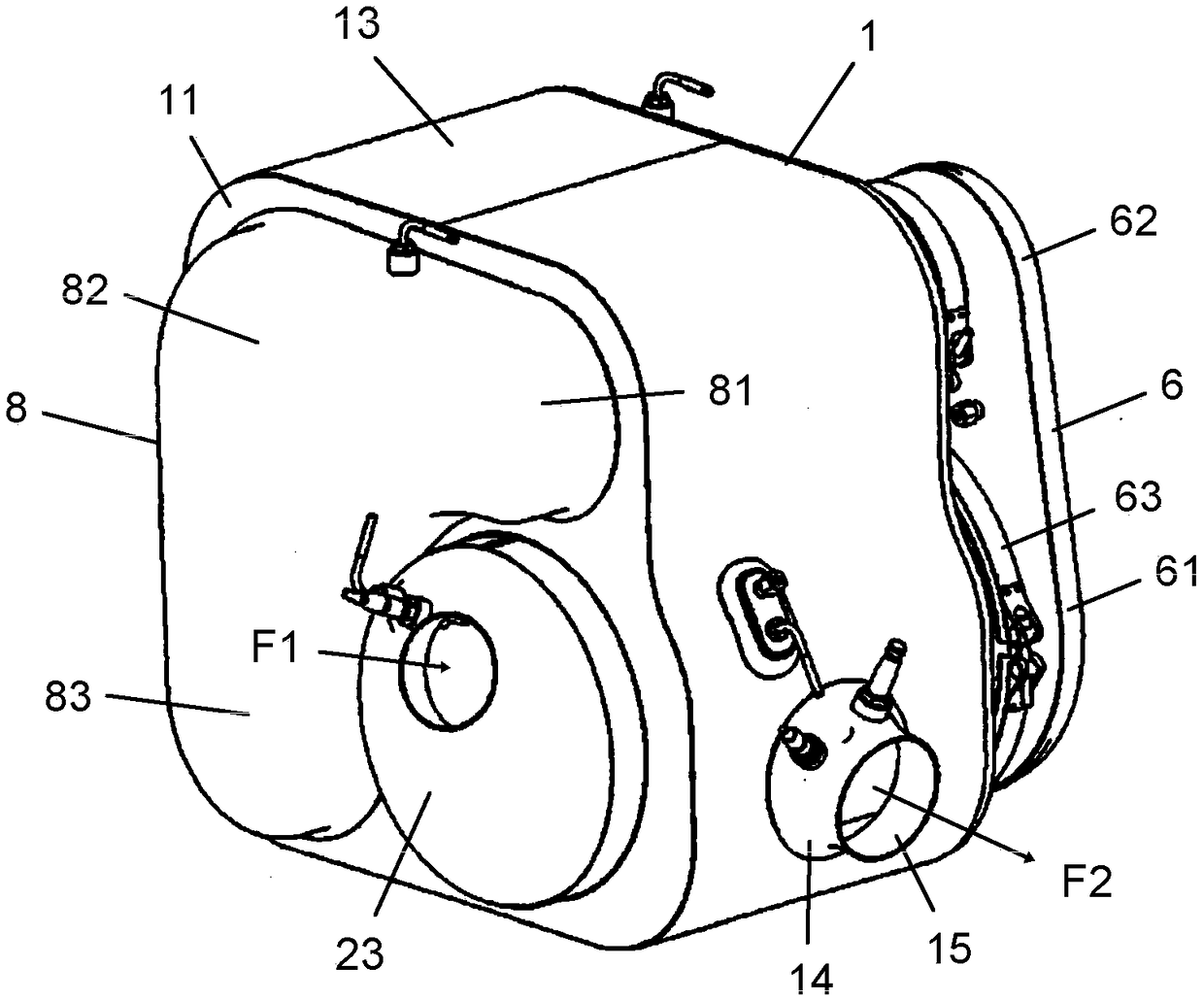

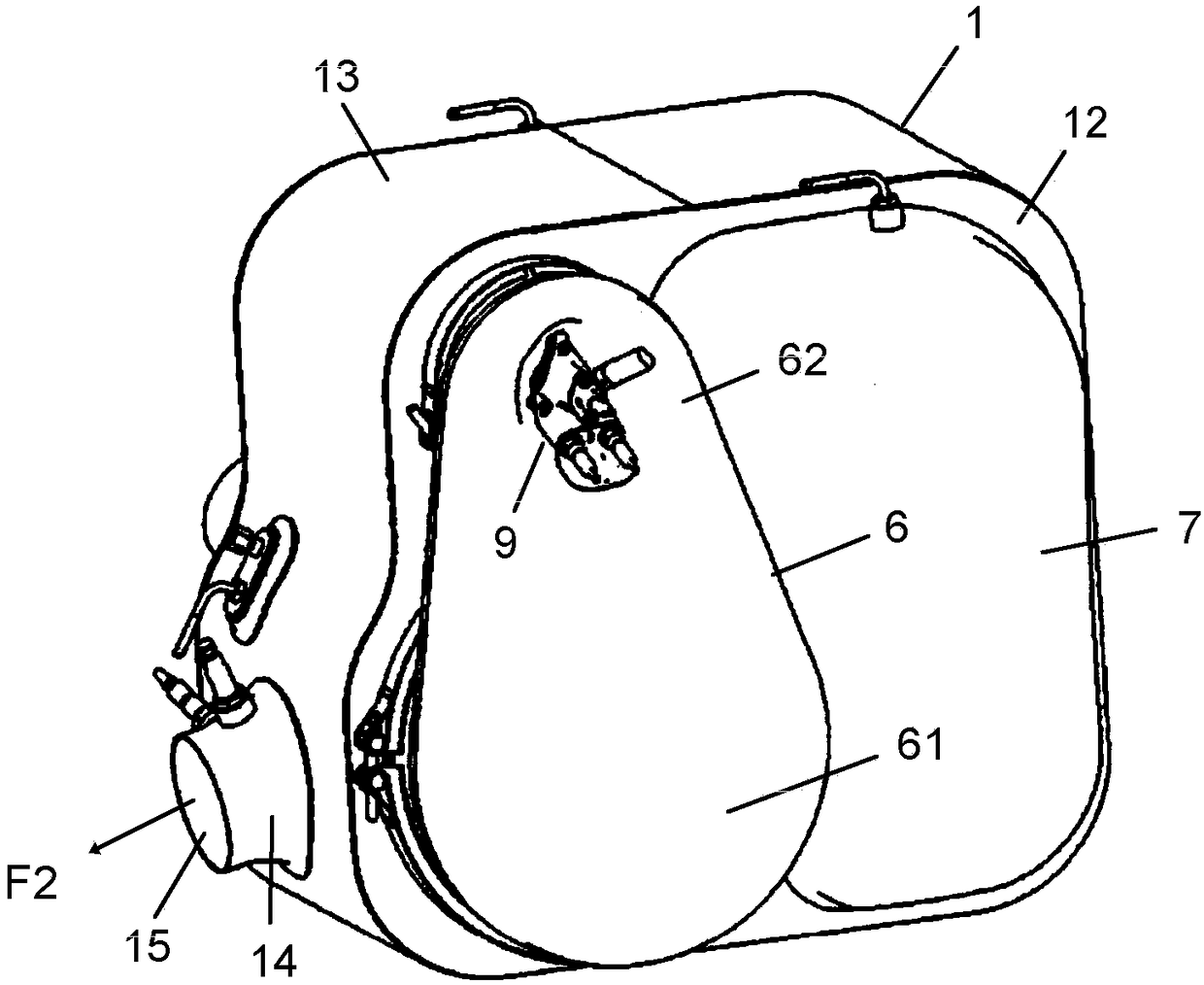

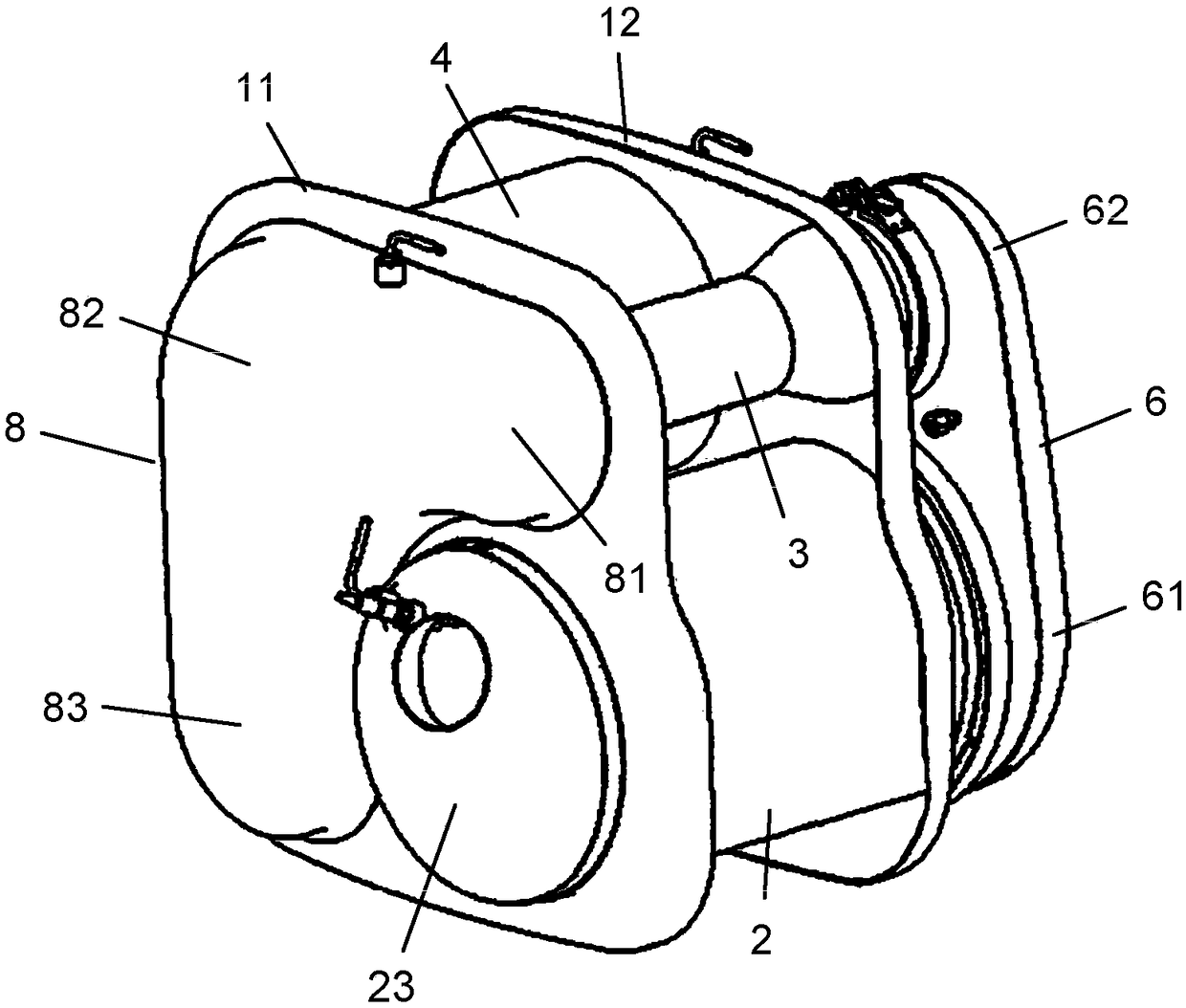

[0034] The present application generally relates to an exhaust gas after-treatment box for treating engine exhaust gas, and the exhaust gas after-treatment box is suitable for being installed on both sides of the vehicle chassis. The exhaust aftertreatment box of the present application is typically suitable for treating the exhaust of a diesel engine; yet, the exhaust aftertreatment box is also applicable to engines that consume other types of fuel (some components in the exhaust aftertreatment box may need to be modified accordingly ).

[0035] An integrated exhaust gas after-treatment box according to a feasible embodiment of the present application will be described below with reference to the accompanying drawings. It should be pointed out that the terms "upstream" and "downstream" used in the following description to represent relative positions are defined relative to the flow direction of the exhaust gas.

[0036] Figures 1 to 6 The integrated exhaust gas after-trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com