Planetary frame structure with self-checking function

A planet carrier and functional technology, applied in the direction of belt/chain/gear, transmission parts, mechanical equipment, etc., can solve the problems of reducing the service life of the gear, increasing the friction and wear of the gear, and the poor lubrication effect of the lubrication system, so as to ensure normal operation The effect of simple operation and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

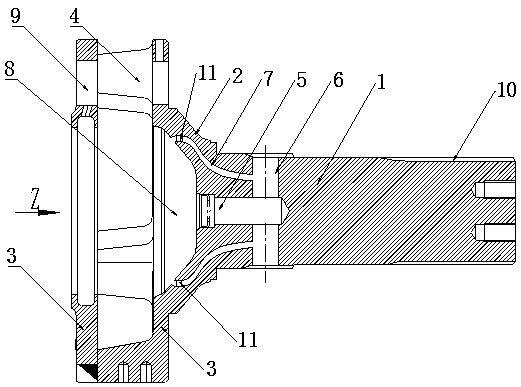

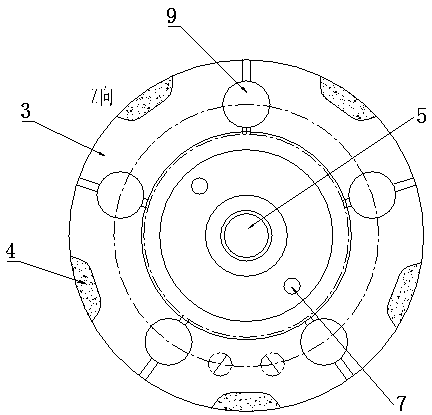

[0013] Such as figure 1 and figure 2 A planet carrier structure with a self-checking function is shown, which includes a shaft body 1, and one end of the shaft body 1 has a bearing mounting seat 2, and the bearing mounting seat 2 is provided with mutually parallel sides 3, and the mutually parallel sides The parts 3 are connected by connecting plates 4. The key point is that: one end of the shaft body 1 is provided with a sun gear shaft installation hole 5, and the side wall of the shaft body 1 is provided with a main oil passage 6, which is installed along the bearing. An auxiliary oil passage 7 is also opened on the side wall of the seat 2, one end of the auxiliary oil passage 7 communicates with the main oil passage 6, and the other end of the auxiliary oil passage 7 communicates with the planetary wheel installation cavity 8, the auxiliary oil pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com