Variable density and gas flow rate smoldering characteristic experiment device and testing method

A technology of gas flow rate and experimental equipment, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of application limitations of experimental instruments, inability to control the density of sample materials, inability to control the flow rate of intake gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In conjunction with the accompanying drawings, the present invention will be described in further detail.

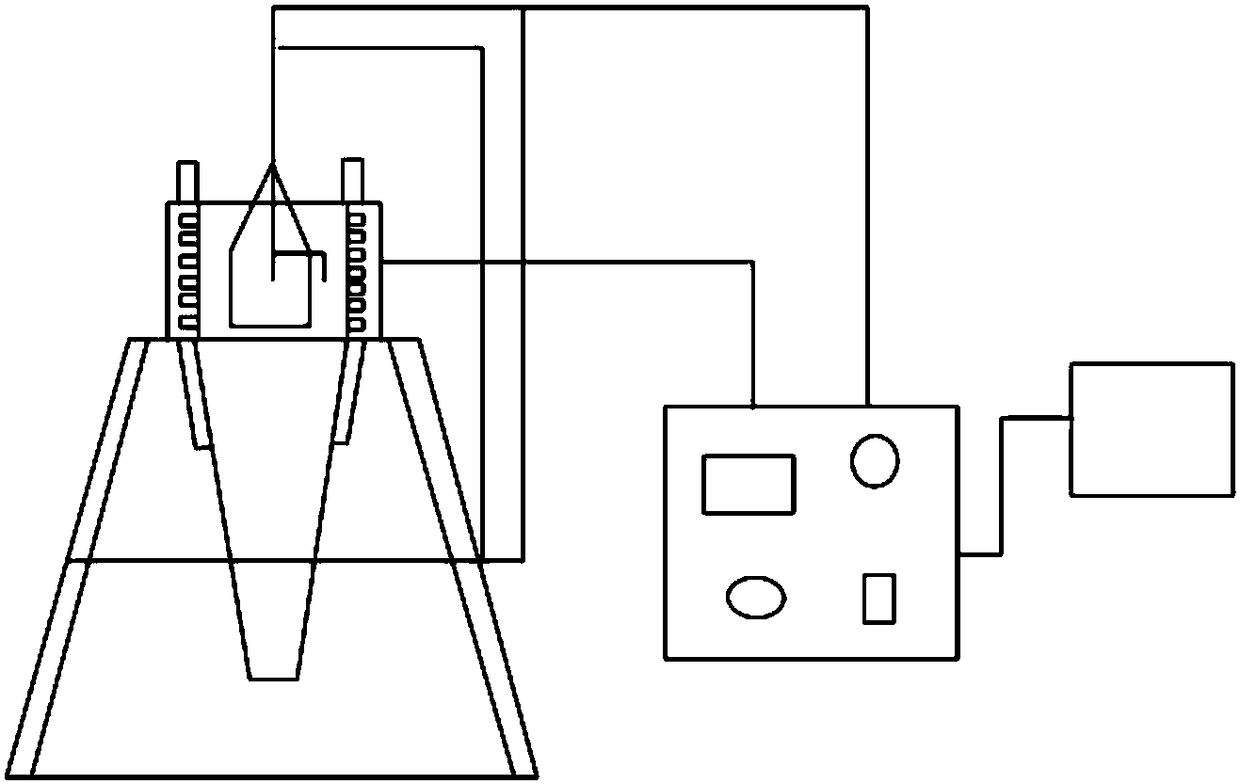

[0036] First, existing technologies such as figure 1 As shown in the schematic diagram of the existing smoldering characteristic detection device, the device can only simply observe the smoldering process, but cannot quantitatively analyze the internal temperature change, heat flow distribution and smoke toxicity of the sample; and it can only be used in a certain The smoldering test under a characteristic experimental condition cannot effectively control the density of the sample material, the flow rate of the intake gas, let alone change the angle of smoldering combustion and the heating area of the auxiliary heating.

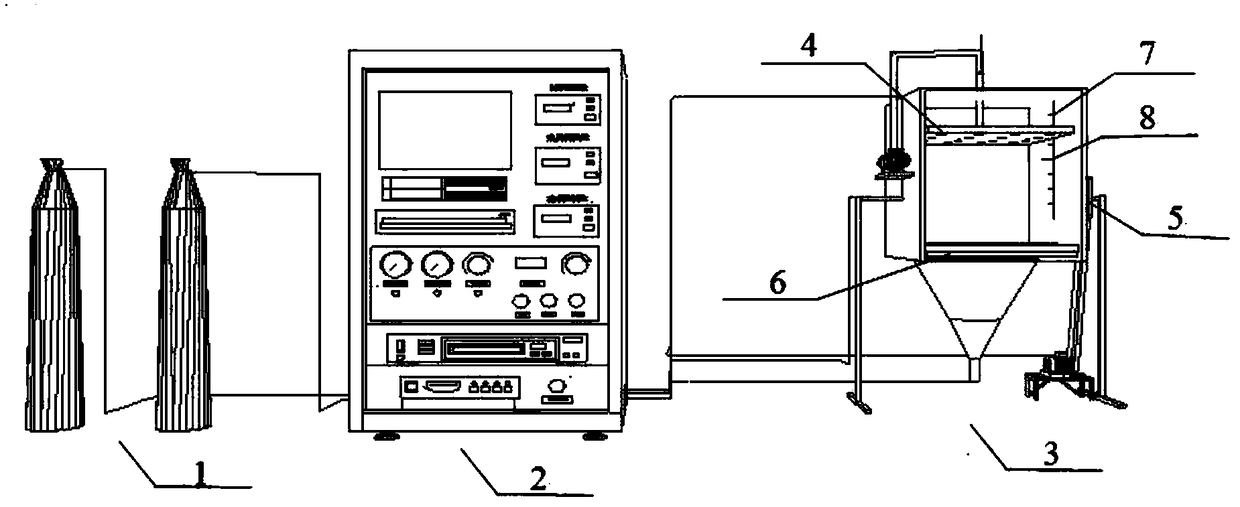

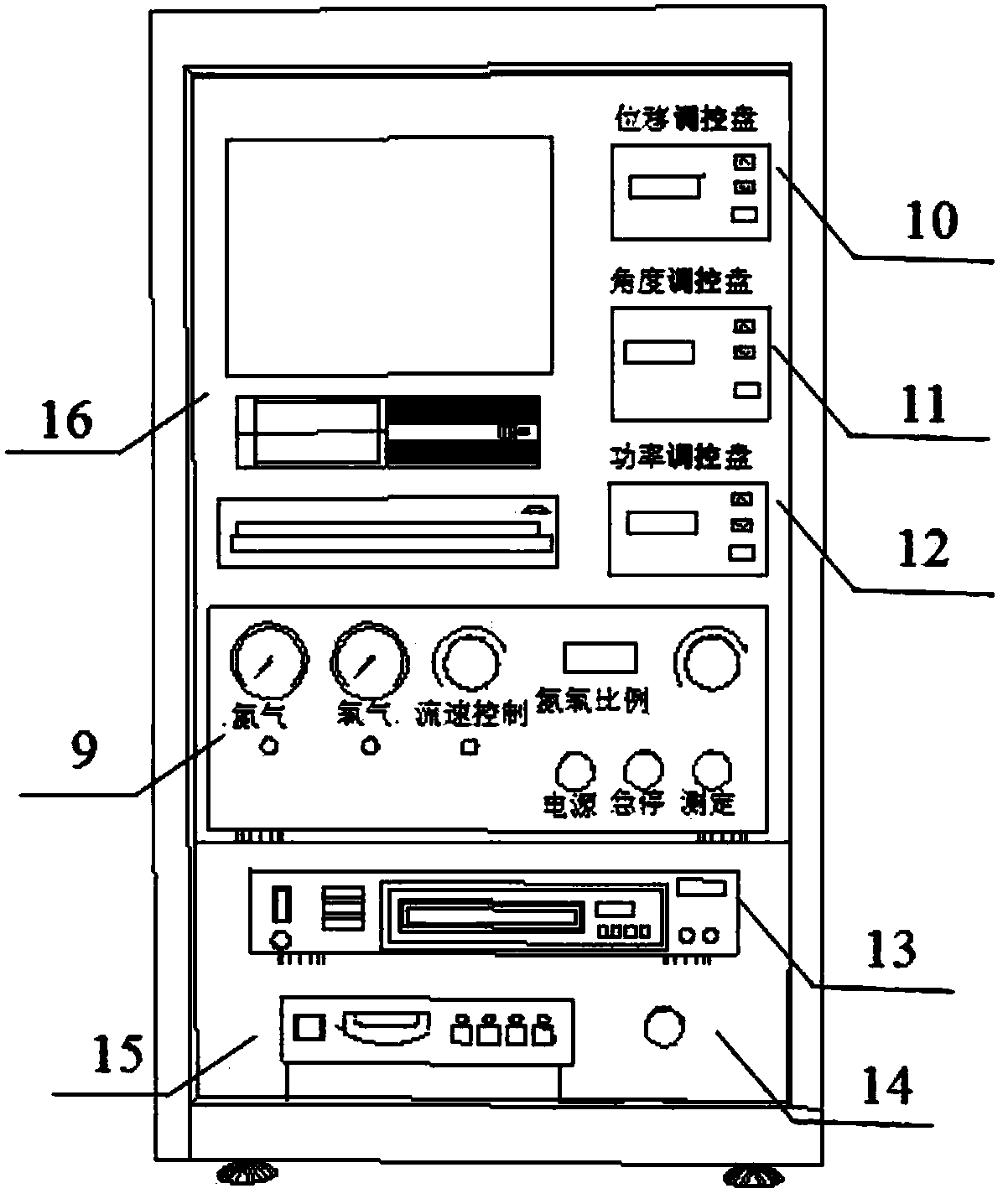

[0037] Such as figure 2 As shown, the smoldering characteristics experimental device of variable density and gas flow rate of the present invention includes a gas storage cylinder group 1, a control analysis platform 2 and a smoldering test b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com