Method for determining wear loss of composite stratum shield hob

A technology for composite strata and determination methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unconsidered impact, inapplicable hob wear prediction, etc., to shorten the construction period and reduce tool change cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052]A subway project is constructed using the shield method. During the construction of the shield through the soft-hard composite stratum, there were several times of opening and changing the cutter, and the hob was seriously worn. Take the first two tool change intervals of this project as an example to illustrate.

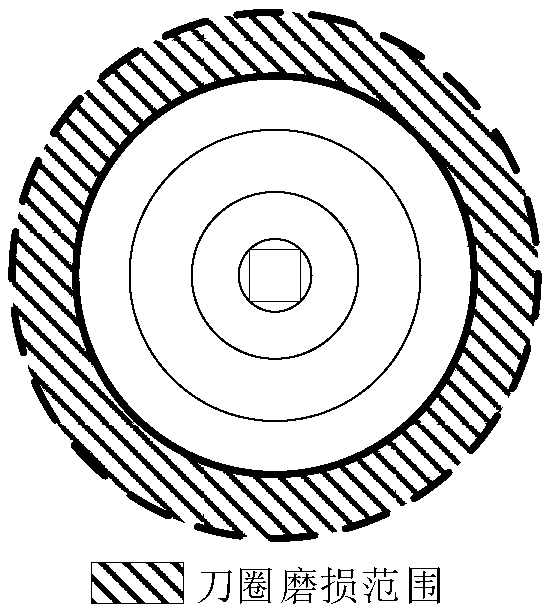

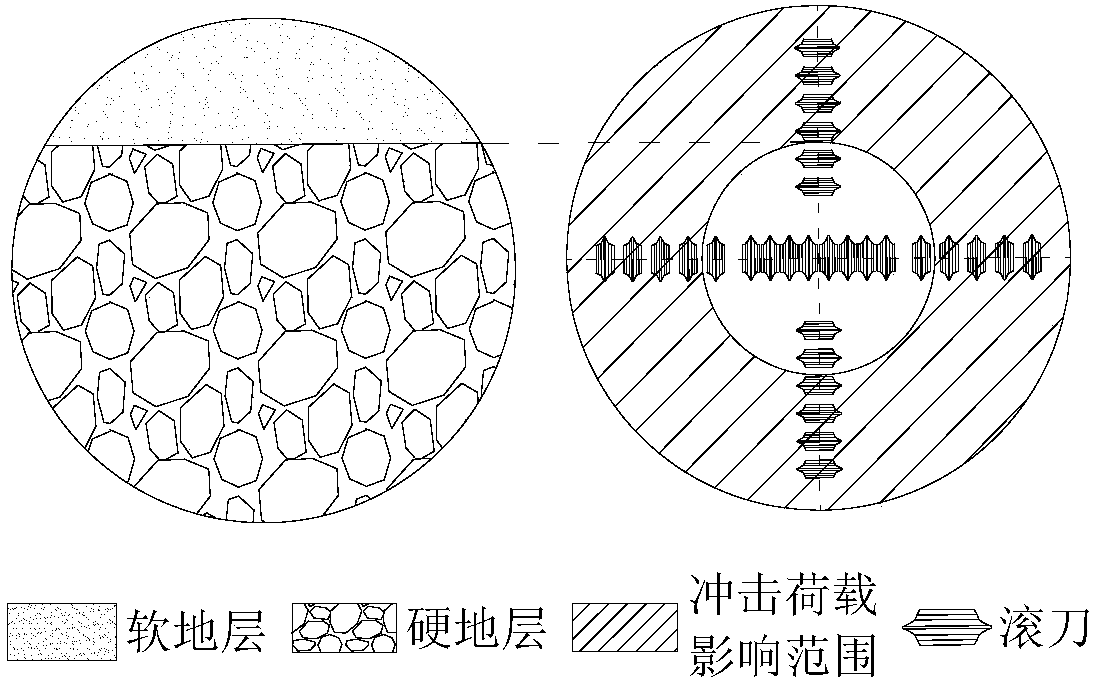

[0053] Such as Figure 1-Figure 3 As shown, a method for determining the wear amount of a shield hob in a composite stratum, the method includes the following steps:

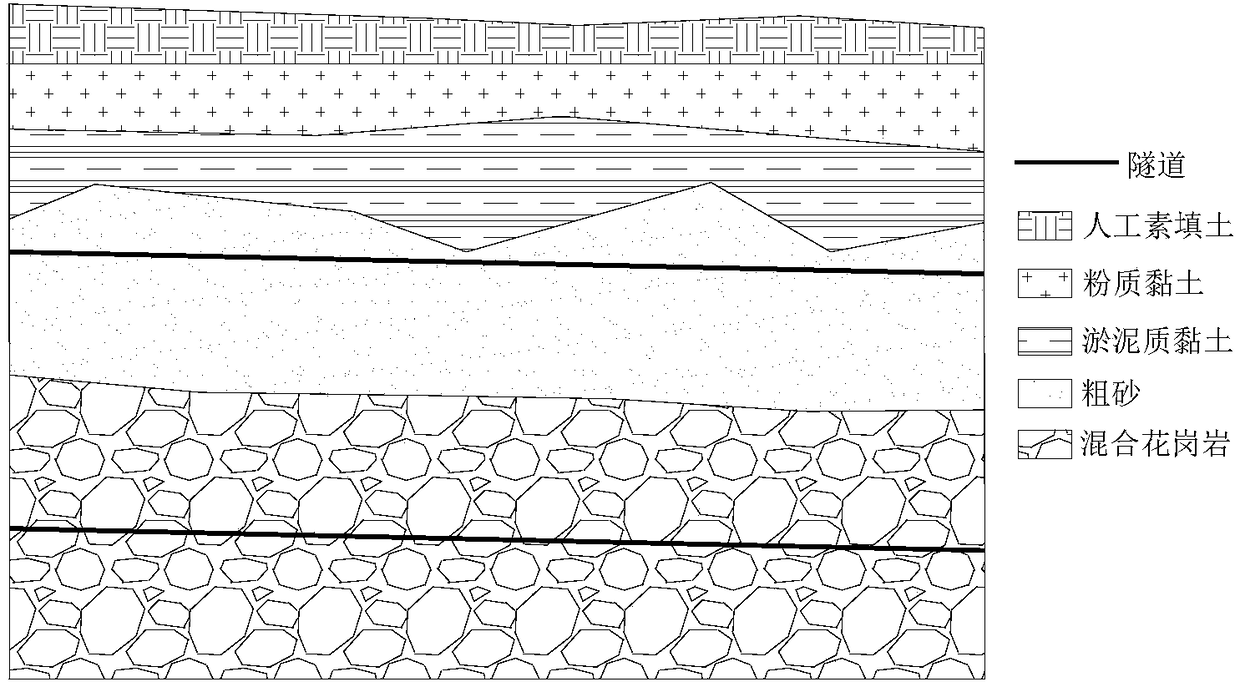

[0054] The first step is to determine the stratum stratification along the tunnel planning route and the stratum strength S of each stratum by drilling method and unconfined compression test.

[0055] In this step, the drilling method refers to: use thick-walled earth-borrowing equipment to drill holes from the surface to the underground every 35m in the construction area to the buried depth of 1.5 times the planned subway line, the surface elevation is 1.12m, and the planned subway line is bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com