A mud-water balance shield machine auxiliary tool change device and its use method

A technology of mud-water balance and tool changing device, which is applied in the directions of manipulator, earthwork drilling, program control manipulator, etc., can solve the problems of unsatisfactory, large environmental damage, unsuitability, etc., to improve the level of automation, reduce the cost of tool change, improve The effect of tool change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with embodiment.

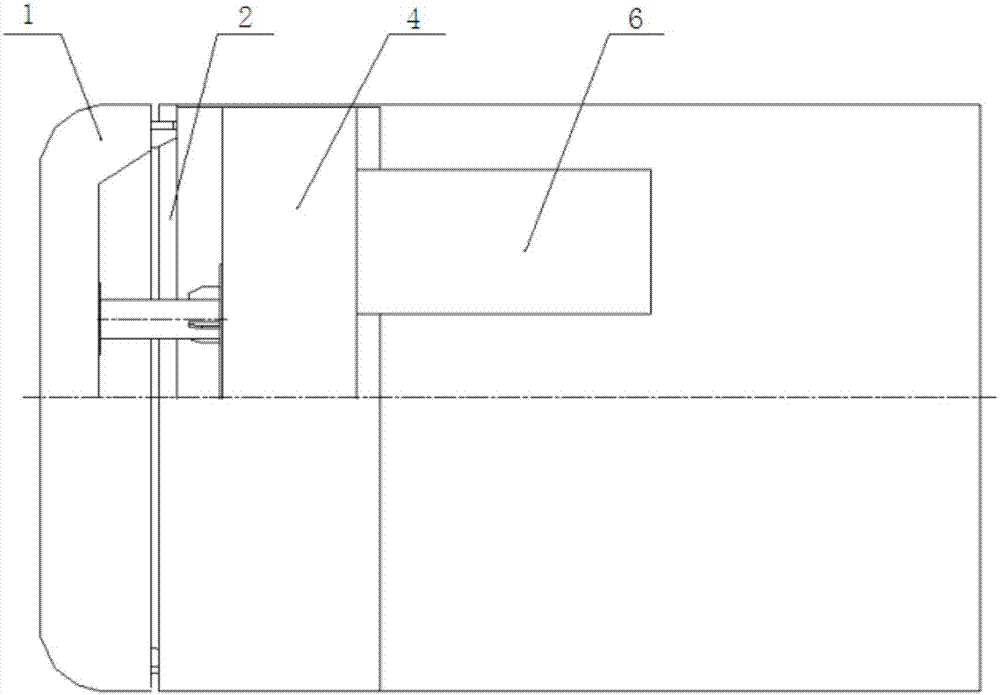

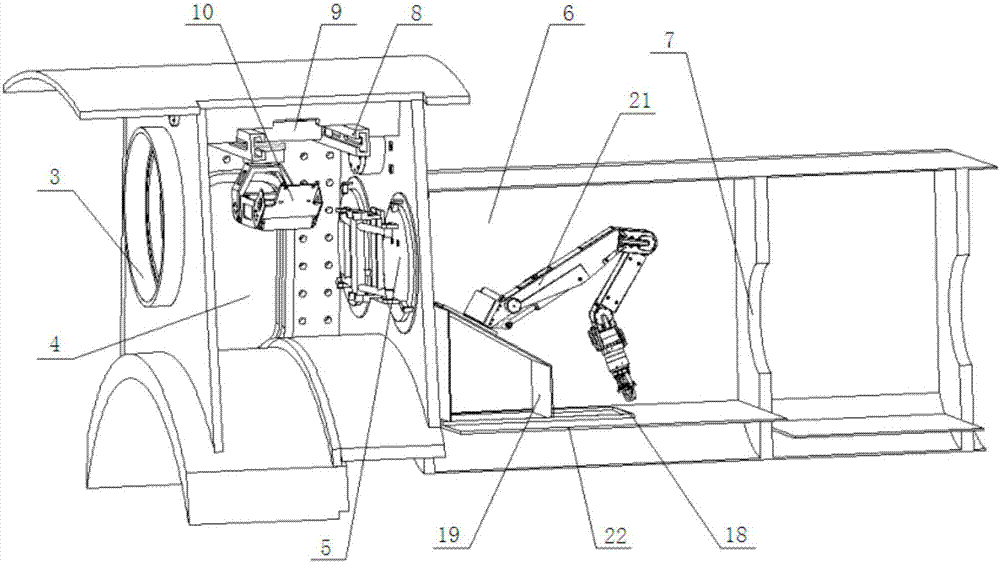

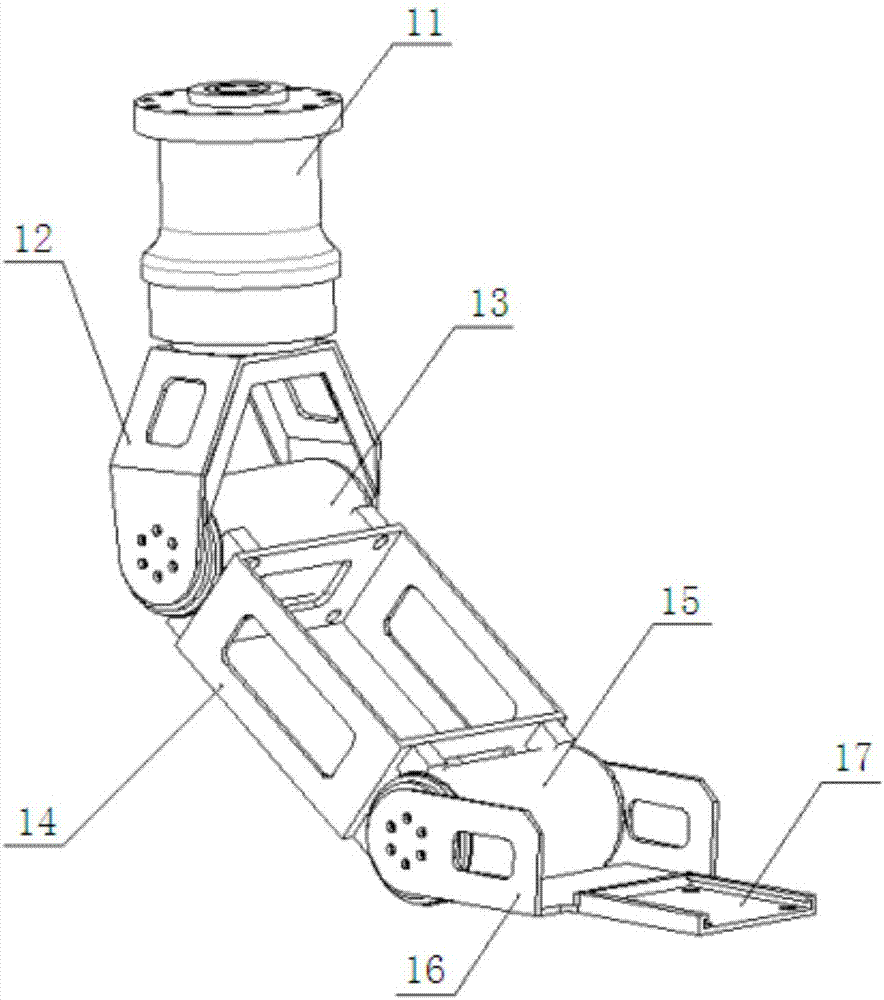

[0038] according to Figure 1 ~ Figure 3As shown in the figure, an auxiliary tool changing device for mud-water balance shield machine is used to assist mud-water balance shield machine to perform tool change operation. Cabin 2, air cushion cabin 4 and man lock cabin, air cushion cabin 4 is located behind the excavation cabin 2, man lock cabin 6 is located behind the air cushion cabin 4, and a first hatch door 3 is opened at the rear of the excavation cabin 2, through which the first cabin The door 3 communicates with the air-cushion cabin 4, and the rear portion of the air-cushion cabin 4 is provided with a second hatch 5, which communicates with the man lock cabin 6 through the second hatch 5, and the third hatch 7 is provided at the rear of the man lock cabin 6, and the operator Enter the man lock cabin 6 through the third cabin door 7; the auxiliary tool changing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com