Distilling automatic control device and application thereof

A technology of automatic control device and controller, which is used in distillation adjustment/control, distillation separation, extractive distillation, etc., can solve the problem that crystals and other forms exist in large quantities in material pipelines or condensers, and it is difficult to ensure stable temperature and extraction yield. It can achieve the effect of large extraction amount, reducing labor intensity and controlling distillation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

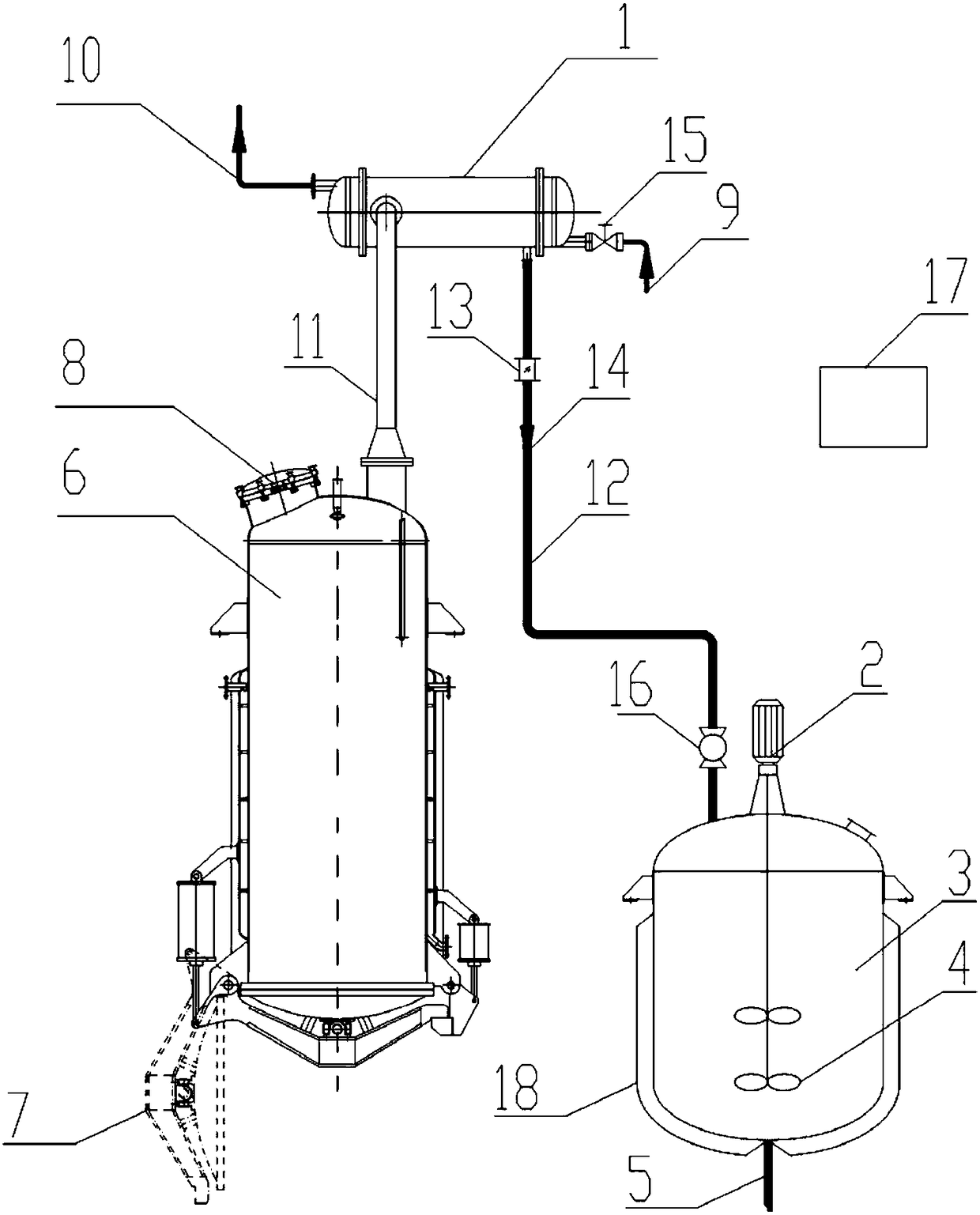

[0020] Such as figure 1 as shown, figure 1 Shown is a distillation automatic control device provided by the present invention, including a condenser 1, a stirring paddle 2, a liquid storage tank 3, a fan blade 4, a discharge port 5, an extraction tank 6, a bottom cover 7, a feed port 8, Condensed water inlet 9 and condensed water outlet 10, material pipeline 1 11, material pipeline 2 12, observation window 13, temperature detection device 14, solenoid valve 1 15, solenoid valve 2 16, controller 17; extraction tank 6 and condenser 1 Connected through the material pipeline 11, the top of the extraction tank 6 is provided with a feeding port 8, and the bottom of the extraction tank 6 is provided with a bottom cover 7; the liquid storage tank 3 and the condenser 1 are connected through the material pipeline 2 12, and the liquid storage tank 3 is equipped with a stirring The paddle 2, the lower end of the stirring paddle 2 has a fan blade 4, and the bottom of the liquid storage ta...

Embodiment 2

[0025] Distillation automatic control device and distillation extraction of paeonol

[0026] Distillation automatic control device is the same as embodiment 1, as figure 1 As shown, 30kg of Cortex Moutan is put into the extraction tank 6 through the feeding port 8, and extracted by water vapor,

[0027] Turn on the condensed water, the controller 17 sets the temperature to two values A=45°C and B=40°C, and observe the color and appearance of the distillate through the wide mouth 13, and the temperature information and status information are connected in real time To the controller 17, the solenoid valve one 15 and the solenoid valve two 16 are controlled by the controller 17 to regulate the collection of the distillate;

[0028] At the same time, the stirring paddle 2 is turned on, the crystallization process is accelerated by the fan blade 3 and the residual crystallization on the inner wall of the liquid storage tank 3 is reduced;

[0029] After the distillation was comp...

Embodiment 3

[0032] Distillation automatic control device and distillation extraction of volatile oil from Auranthus nudica

[0033] Distillation automatic control device is the same as embodiment 1, as figure 1 As shown, put 25 kg of the aboveground part of the naked flower purple pearl into the extraction tank 6 through the feeding port 8, and extract it with steam.

[0034] Turn on the condensed water, the controller 17 sets the temperature to two values A=40°C and B=35°C, and observe the color and appearance of the distillate through the wide mouth 13, and the temperature information and status information are connected in real time To the controller 17, the solenoid valve one 15 and the solenoid valve two 16 are controlled by the controller 17 to regulate the collection of the distillate;

[0035] After the distillation was completed, the volatile oil gained in the liquid storage tank 3 was discharged from the outlet 5 for collection.

[0036] Collect the volatile oil of Aurora nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com