Cement block dissolving device for preparing concrete

A technology for concrete and deblocking, which is applied in solid separation, sieves, grids, etc., can solve the problems of not being able to save manpower to complete deblocking and preventing clogging, and achieve the effect of saving manpower and avoiding clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

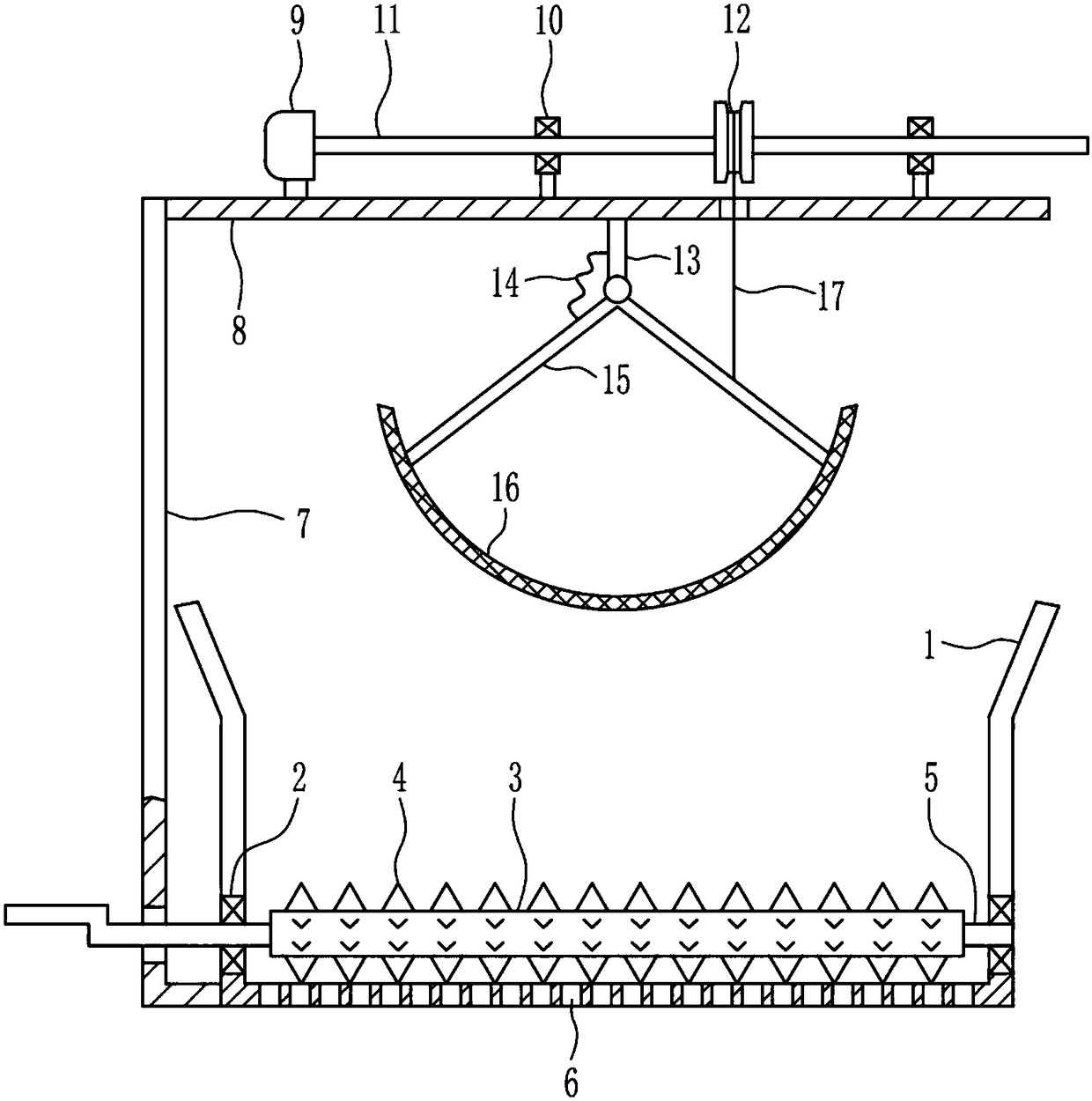

Embodiment 1

[0022] A cement deblocking equipment for preparing concrete, such as Figure 1-3 As shown, it includes a deblocking frame 1, a first bearing seat 2, a drum 3, a crushing tooth 4, a first rotating rod 5, a left frame 7, a top plate 8, a servo motor 9, a second bearing seat 10, and a second rotating rod 11. Winding reel 12, fixed rod 13, first spring 14, connecting rod 15, arc-shaped filter screen plate 16 and pull cord 17, small holes 6 are evenly opened on the bottom wall of deblocking frame 1, and the left side of deblocking frame 1 The bottom is connected with the left frame 7, the bottom of the left and right walls of the unblocking frame 1 is connected with the first bearing seat 2, the first bearing seat 2 is connected with the first rotating rod 5, and the first rotating rod 5 passes through the first rotating rod on the left side. Bearing seat 2 and the lower part of the left frame 7, the first rotating rod 5 is connected with the drum 3, the drum 3 is located in the de...

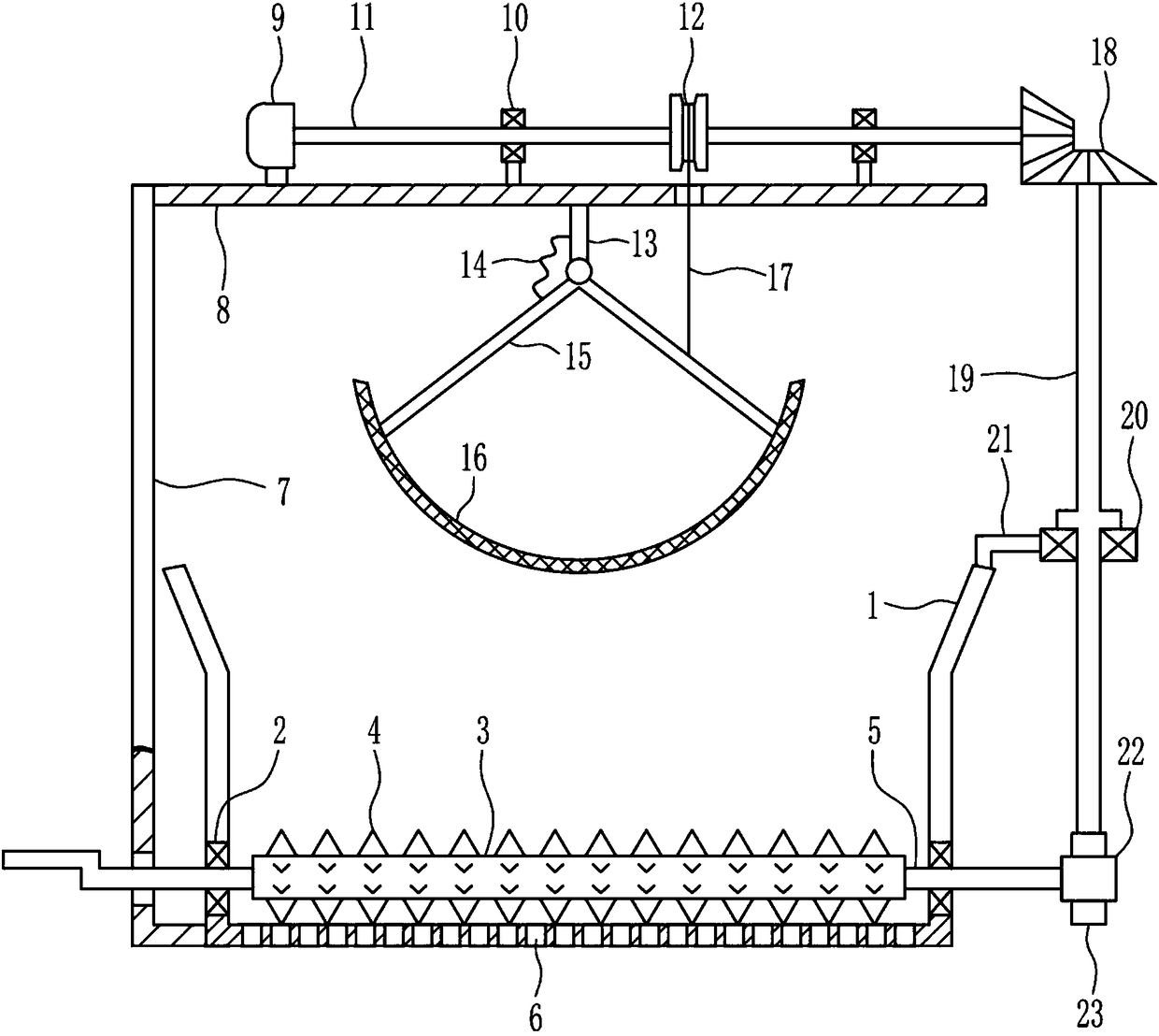

Embodiment 2

[0024] A cement deblocking equipment for preparing concrete, such as Figure 1-3 As shown, it includes a deblocking frame 1, a first bearing seat 2, a drum 3, a crushing tooth 4, a first rotating rod 5, a left frame 7, a top plate 8, a servo motor 9, a second bearing seat 10, and a second rotating rod 11. Winding reel 12, fixed rod 13, first spring 14, connecting rod 15, arc-shaped filter screen plate 16 and pull cord 17, small holes 6 are evenly opened on the bottom wall of deblocking frame 1, and the left side of deblocking frame 1 The bottom is connected with the left frame 7, the bottom of the left and right walls of the unblocking frame 1 is connected with the first bearing seat 2, the first bearing seat 2 is connected with the first rotating rod 5, and the first rotating rod 5 passes through the first rotating rod on the left side. Bearing seat 2 and the lower part of the left frame 7, the first rotating rod 5 is connected with the drum 3, the drum 3 is located in the de...

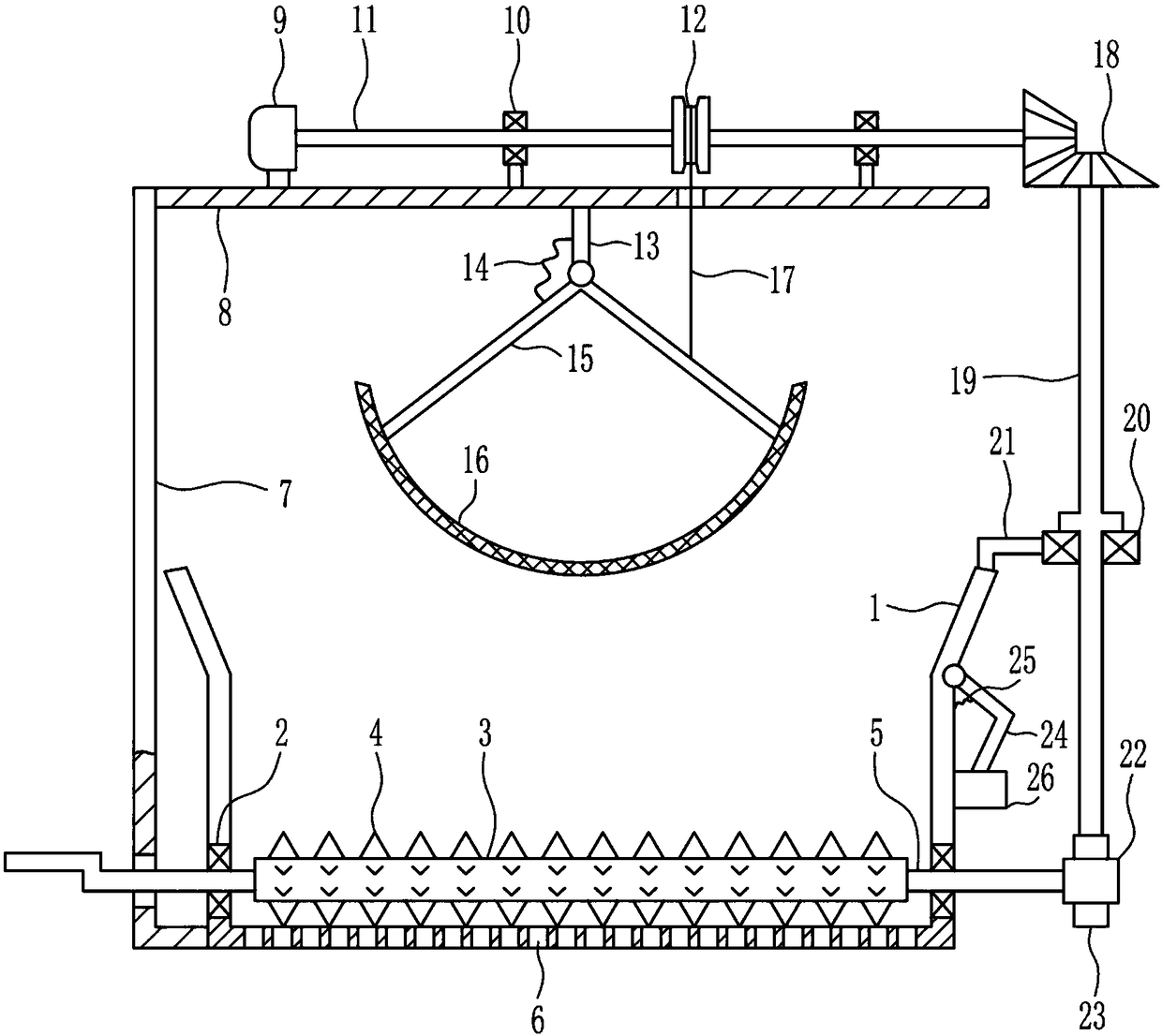

Embodiment 3

[0027] A cement deblocking equipment for preparing concrete, such as Figure 1-3As shown, it includes a deblocking frame 1, a first bearing seat 2, a drum 3, a crushing tooth 4, a first rotating rod 5, a left frame 7, a top plate 8, a servo motor 9, a second bearing seat 10, and a second rotating rod 11. Winding reel 12, fixed rod 13, first spring 14, connecting rod 15, arc-shaped filter screen plate 16 and pull cord 17, small holes 6 are evenly opened on the bottom wall of deblocking frame 1, and the left side of deblocking frame 1 The bottom is connected with the left frame 7, the bottom of the left and right walls of the unblocking frame 1 is connected with the first bearing seat 2, the first bearing seat 2 is connected with the first rotating rod 5, and the first rotating rod 5 passes through the first rotating rod on the left side. Bearing seat 2 and the lower part of the left frame 7, the first rotating rod 5 is connected with the drum 3, the drum 3 is located in the deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com