Device and method for induction brazing

A technology of induction brazing and sensors, which is applied in the field of modular fast-switching induction brazing devices, can solve the problems of long adjustment time, complex equipment structure, poor versatility, etc., shorten the switching time and switching difficulty, and simplify the switching process and steps, the effect of increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

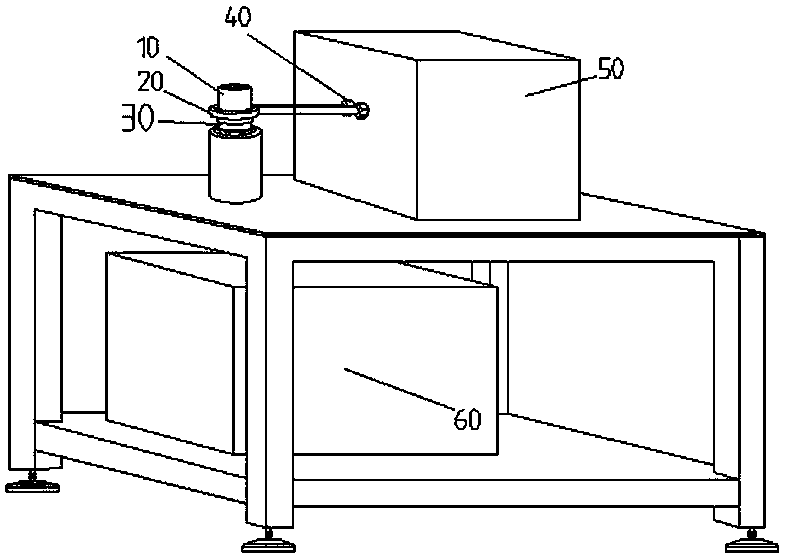

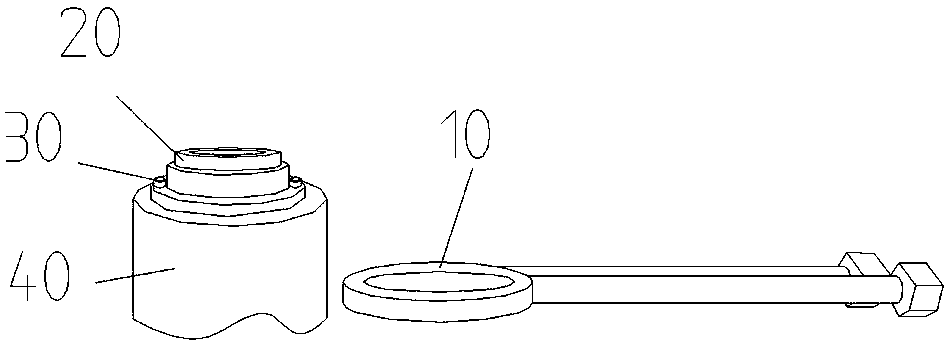

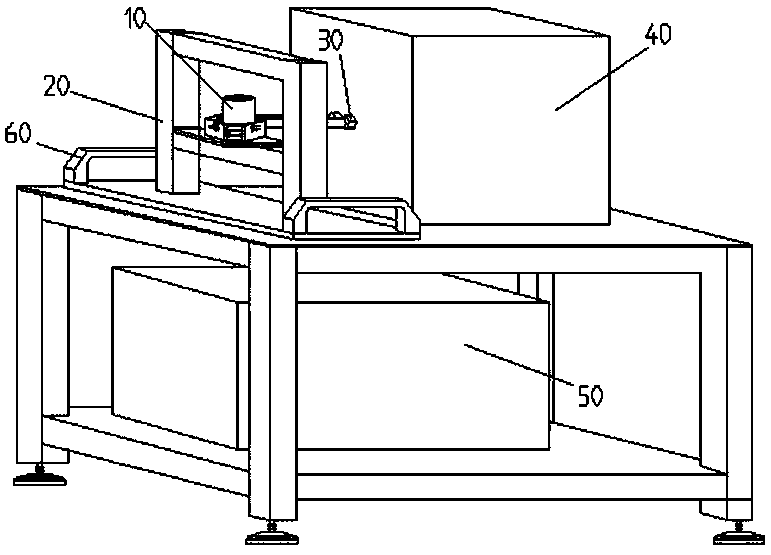

[0026] Representative embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims, all of which are within the scope of the present invention.

[0027] During induction brazing, the relative position and distance between the workpiece and the sensor are the most critical factors affecting the quality and stability of the workpiece brazing. During brazing, the relative position and distance between the workpiece and the sensor must be kept within the range specified by the process. And keep it constant throughout the brazing process, otherwise the induction brazing stability and brazing pass rate will fluctuate. The most important purpose of the design and manufacture of positioning tooling is to keep the relative position and distance between the workpiece and the sensor within the specified range of the process, and to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com