Implementation scheme of numerical control machining full-automatic production line

A production line, fully automatic technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of large errors and many mistakes, and achieve the effect of eliminating tedious work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with specific embodiments.

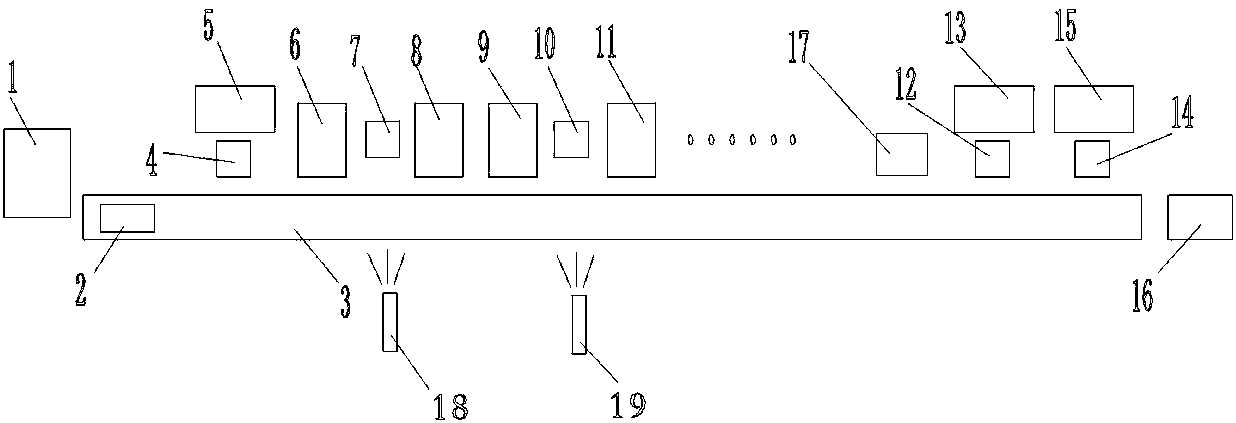

[0009] Such as figure 1 As shown, 1 is the central control system, and 2 to 17 are the entire automatic production line. The operation of the production line is all controlled by the central control system (1), and all real-time data is fed back into the central control system. The central control system (1) is based on the production line The real-time situation determines the next step of the production line. The production manager supervises the entire production process through the central control system (1) in the control room. There is not a single worker in the entire production line, and all are fully automated.

[0010] 2 in the figure is the feeding area, which is the front end of the intelligent conveying line (3). After the workpiece is put into the loading area (2), the central control system (1) will receive a signal to start the working mode, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com