Bearing right-angle turning mechanism and application of the same to bearing bush grinding and super-finishing automation line

A technology of right-angle turning and bearing sleeves, which is applied in the field of bearing manufacturing, can solve problems such as unsmooth transportation, unsuitable transportation, and material jams, and achieve the effect of eliminating unsmooth transportation and material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

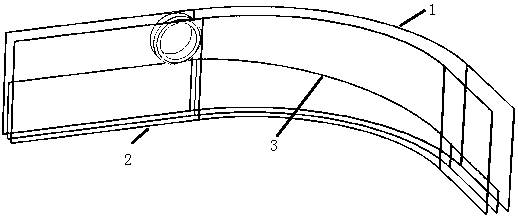

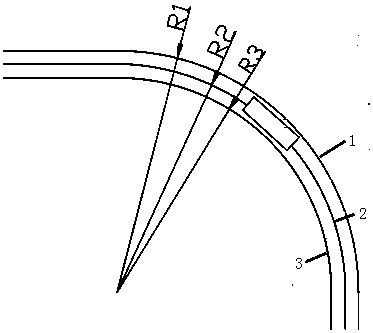

[0033] Embodiment 1: The bearing right-angle turning mechanism is used to transport the outer ring of the bearing, the plate thickness is 0.5 mm, and ε is 5 mm.

Embodiment 2

[0034] Embodiment 2: The bearing quarter-turn mechanism is used to transport the inner ring of the bearing. The plate thickness is 1.5 mm, ε is 7 mm, and the outer diameter of the bearing refers to the rib diameter of the inner ring.

Embodiment 3

[0035] Embodiment 3: The bearing right-angle turning mechanism is used to transport the inner ring of the bearing. The plate thickness is 2mm, ε is 10mm, and the outer diameter of the bearing refers to the rib diameter of the inner ring.

[0036] The existing bearing ring conveying device is like the horizontal feeding chute disclosed in Chinese Invention Patent Publication No. CN104743333A. Distributed between the feeding table and the vertical feeding assembly, this kind of horizontal feeding chute cannot be applied between the immediately preceding station and the immediately following station that are not in a straight line with each other, because the bearing ring has a certain width and diameter , if there is no suitable turning radius, that is: the proper distance between the outer and inner bending plates, the bearing ring will have unsmooth delivery or material jams when cornering. Therefore, the present invention provides a standard for this kind of need, and can des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com