Round cylinder head assembly of refrigerating compressor

A refrigeration compressor and cylinder head technology, which is applied in the field of compressors, can solve the problems of heavy design of the cylinder head, affecting the cylinder hole, and large space occupied by the cylinder head, so as to achieve a better working environment for the piston, save material costs, and occupy less space. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

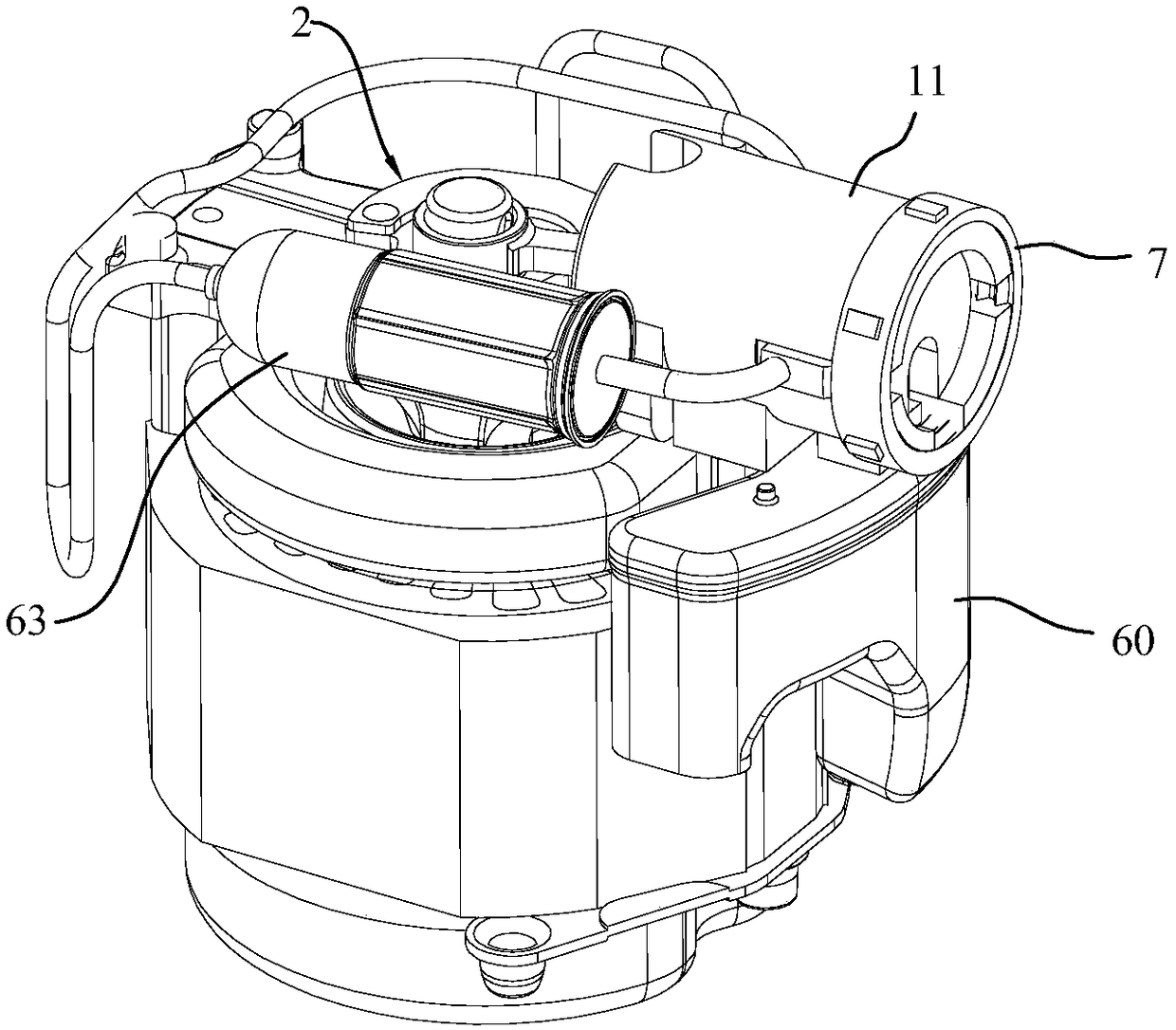

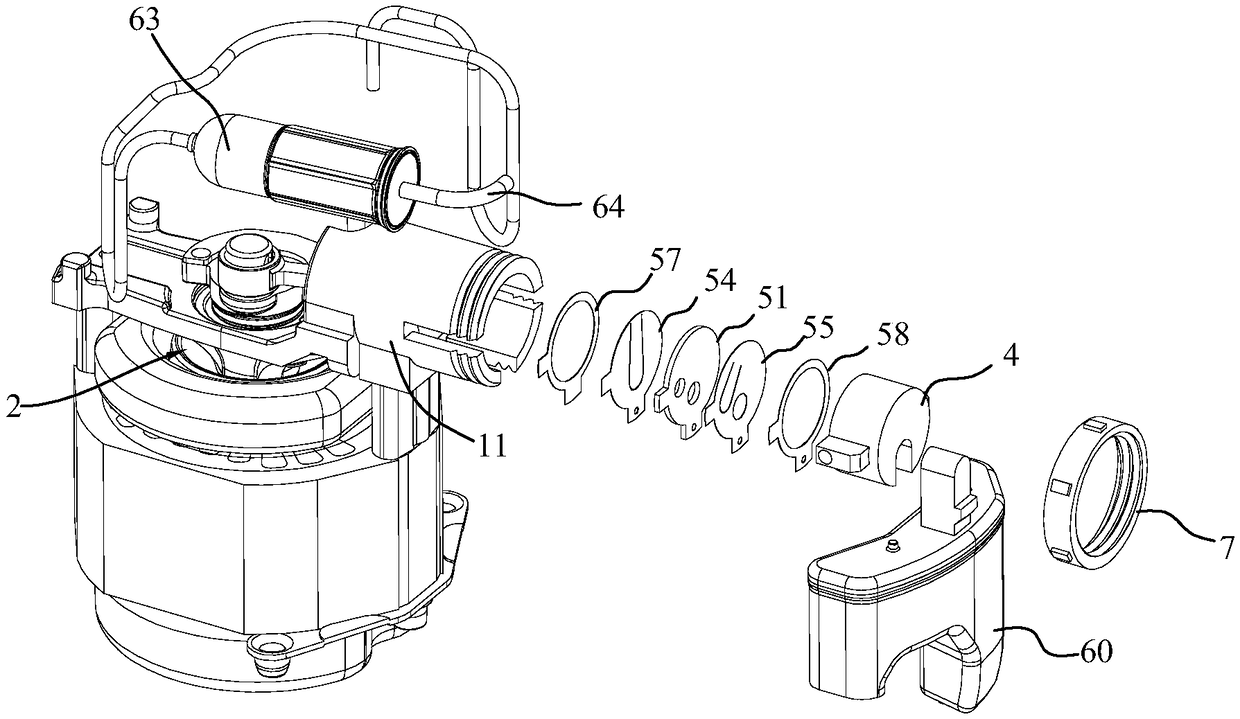

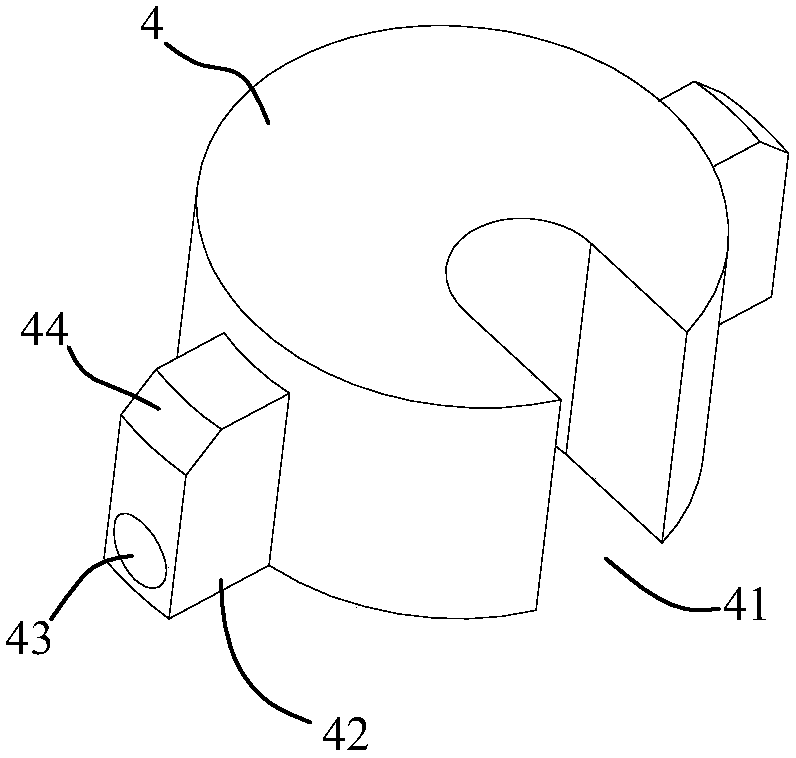

[0043] refer to Figure 1-Figure 19 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each component of the present invention will be described in detail below.

[0044] The present invention provides a circular cylinder head assembly of a refrigeration compressor, comprising a cylinder block 1 and a cylinder head assembly, the cylinder block 1 is provided with a cylinder block 11, and the cylinder block 11 has a cylinder hole inside, and the cylinder block 11 There is a circular cylinder head 12 at the far end, and the inside of the cylinder head 12 has a mounting hole. The cylinder head assembly includes an intake valve, an exhaust valve, a cylinder cover 4 and can be connected with the cylinder head 12 to connect the intake valve, The exhaust valve and the cylinder head 4 define fasteners in the installation hole, and the cylinder head 4 is provided with an air intake passage communicated with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com