A flexible wearable resistive strain sensor and its preparation method

A resistive sensor and resistive strain technology, which is applied in the direction of sensors, electric/magnetic solid deformation measurement, applications, etc., can solve the problems of different sensitivity of sensors, reduced service life, and disorderly arrangement of micron-scale crack structure sizes, etc., to ensure Sensitivity and stability, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

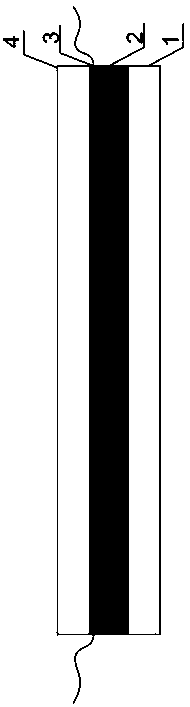

[0041] Such as figure 1 and figure 2 As shown, a flexible wearable resistive strain sensor, which includes

[0042] barrier layer 1,

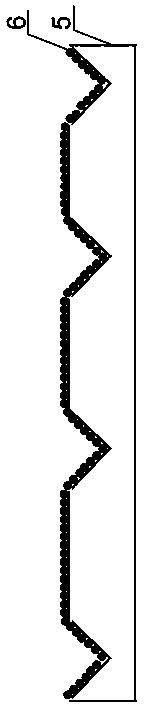

[0043] The sensing layer 2, the sensing layer 2 includes a micro-nano structure layer 5 and a sensitive layer 6, wherein the structural layer 5 is formed on the upper surface of the barrier layer 1, and the sensitive layer 6 is formed on the upper surface of the structural layer 5;

[0044] The electrode layer 3 includes two electrodes drawn from the surface of the sensitive layer 6;

[0045] The protective layer 4, the protective layer is located above the electrode layer.

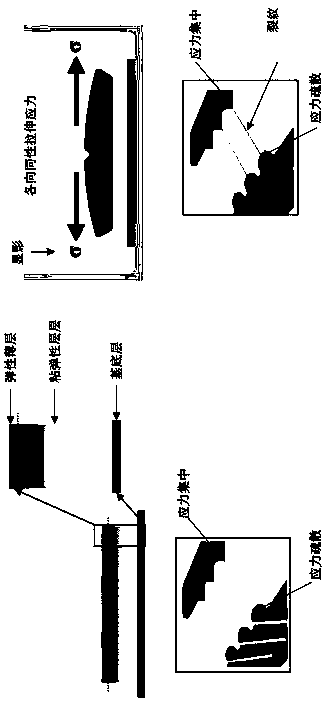

[0046] First, the preparation of the structural layer 5, the template structure used in it, and the principle of crack formation are as follows: image 3 , Figure 4 Shown:

[0047] (1), SU-8 negative photoresist is evenly coated on the silicon substrate by spin coating, with a thickness of 15 μm, and soft baked in an oven at 90 ° C for 3 minutes;

[0048] (2), put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com