Ultra-low temperature optical fiber tip timing sensor

A blade tip timing and sensor technology, used in instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problems of non-contact blade vibration monitoring and failure to work normally, and achieve easy on-site wiring and prevent low-temperature deformation. , the effect of good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

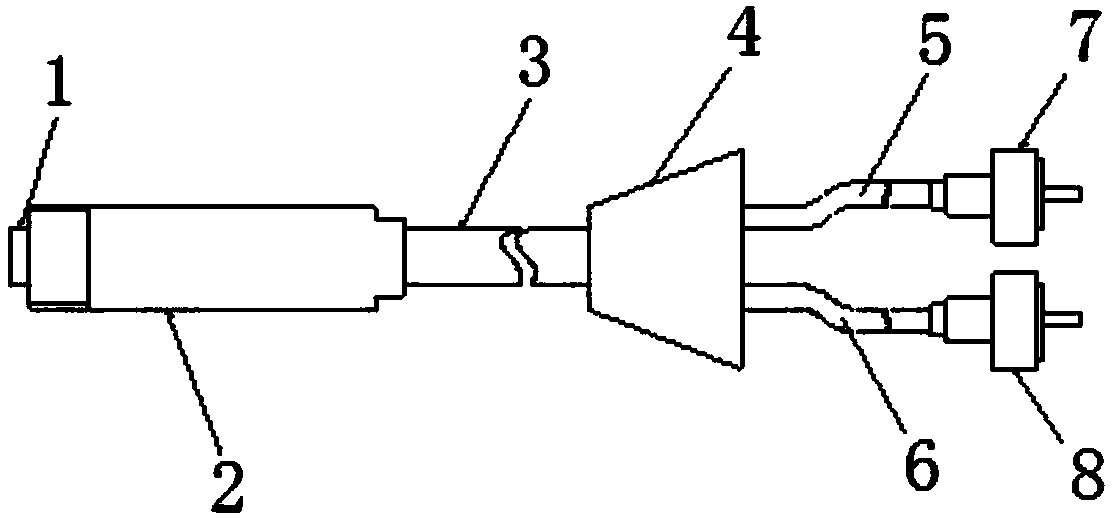

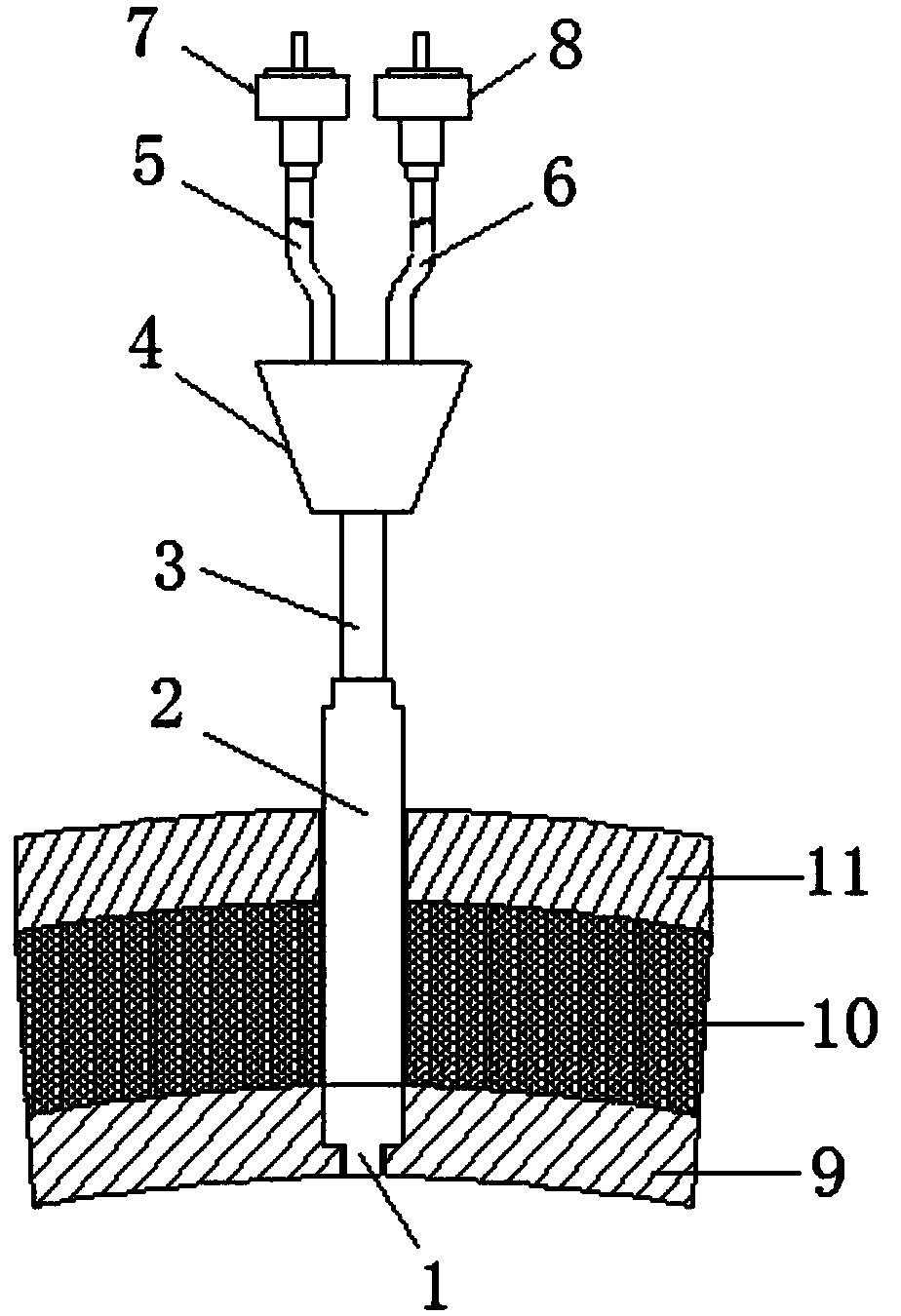

[0019] Such as figure 1 As shown, an ultra-low temperature optical fiber blade tip timing sensor of the present invention includes a sensor probe 1, and the sensor probe 1 is composed of a metal casing and an emitting optical fiber and a receiving optical fiber arranged inside it, wherein the emitting optical fiber is used for emitting light Signal (1 transmitting optical fiber), the receiving optical fiber is used to receive the reflected light signal of the blade (6 or more receiving optical fibers). The metal shell of the sensor probe 1 and the transmitting optical fiber and receiving optical fiber inside are fixed with ultra-low temperature resin glue, and the minimum temperature resistance is -270°C. Both the transmitting fiber and the receiving fiber can be made of low-temperature fiber, such as using PI-coated quartz fiber, the minimum temperature resistance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com