Bullet train wheel intelligent magnetic particle flaw detector

A technology of magnetic particle flaw detection and wheels, applied in the direction of material magnetic variables, etc., can solve the problems of high manpower and material resources costs, limit the working efficiency of magnetic particle detection devices, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

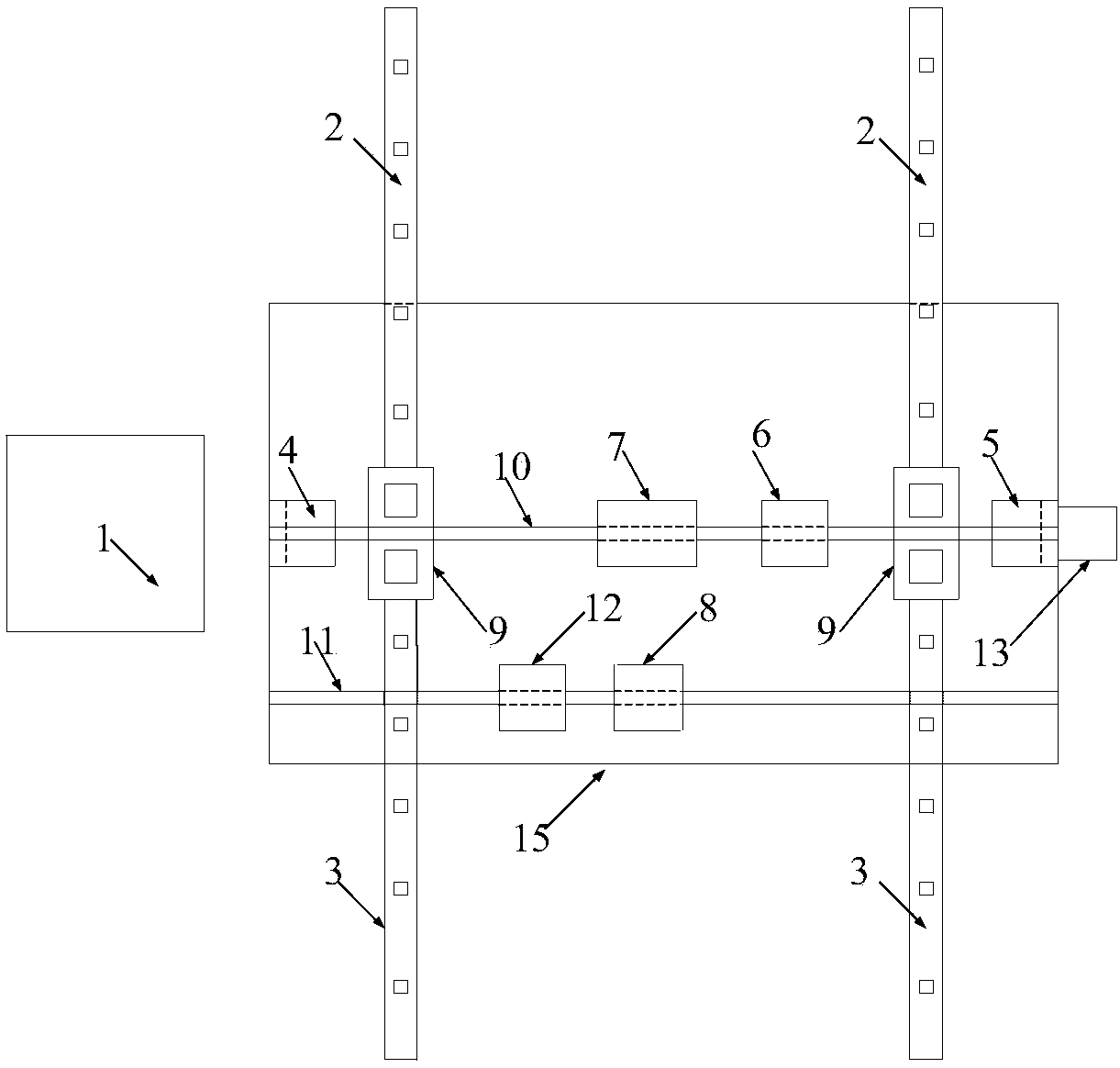

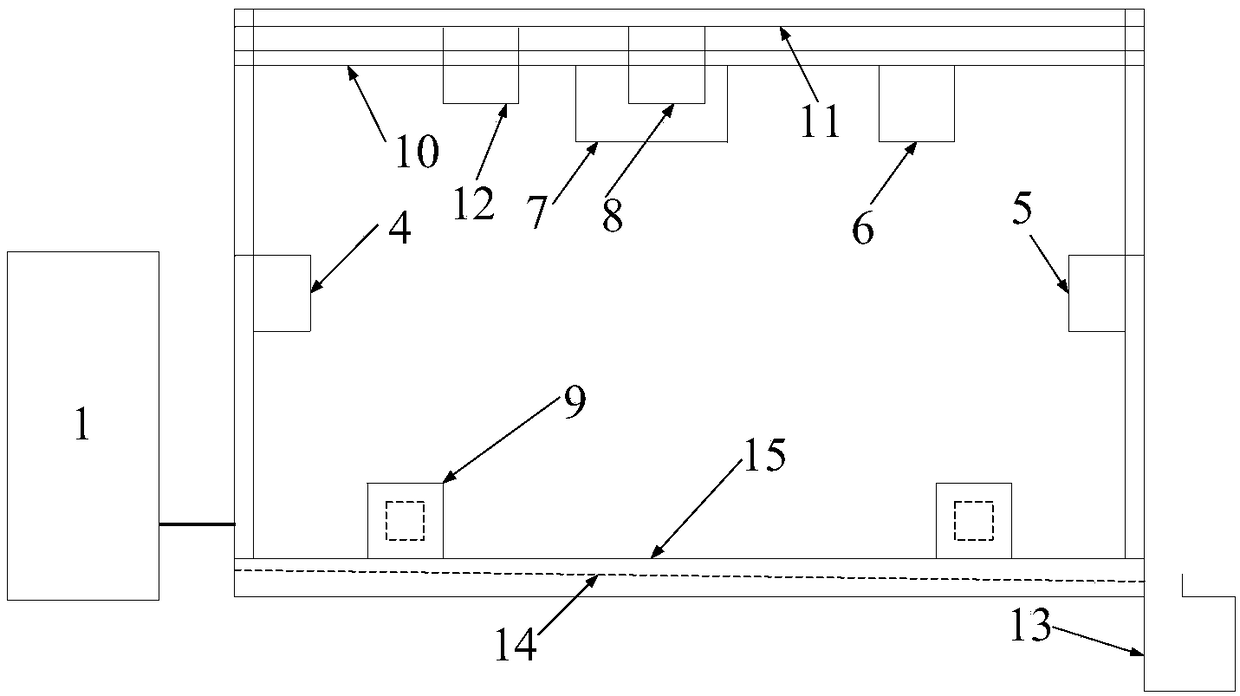

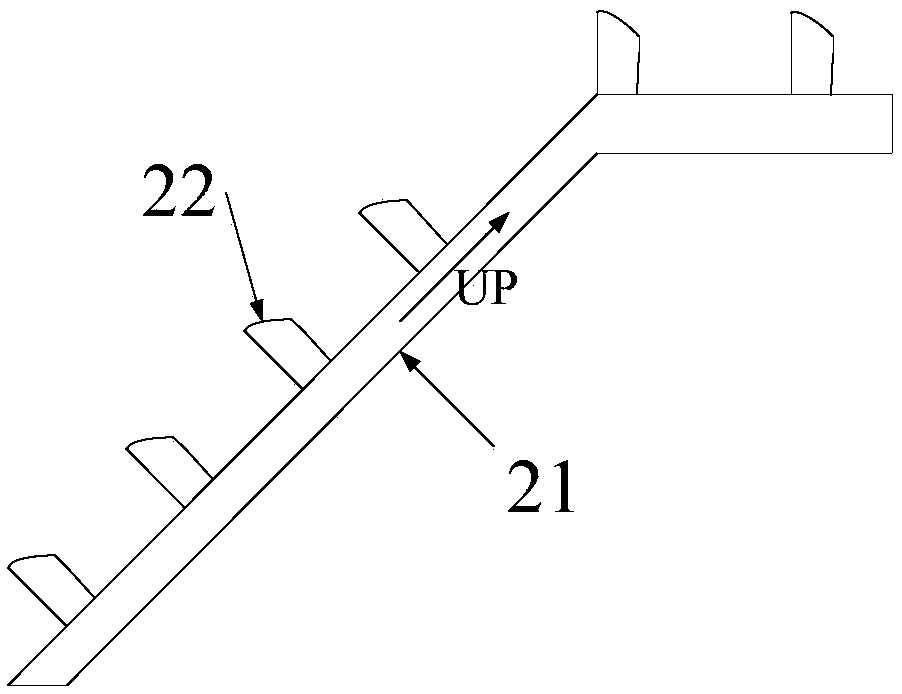

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

[0024] Such as Figure 1-6 As shown, the reference signs are: control center 1, feeding bracket 2, unloading bracket 3, excitation-demagnetization coil 4, fastening connector 5, first magnetic probe 6, image detection element 7, second magnetic probe 8 , detection support 9, detection bracket 10, retest bracket 11, marking element 12, magnetic suspension accumulation tank 13, magnetic suspension storage element 14, base 15, loading bracket guide rail 21, loading bracket stopper 22, unloading bracket Guide rail 31, blanking bracket stopper 32, magnetic suspension nozzle 71, color image acquisition element 72 equipped with long-wave ultraviolet auxiliary light source, active dynamic detection support wheel 91, passive dynamic detection support wheel 92.

[0025] An intelligent magnetic particle flaw detection machine for motor vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com