Gas sensing characteristic response curve testing device

A response curve and testing device technology, which is applied in the field of gas sensitive materials and gas sensors, can solve problems such as unsatisfactory, poor repeatability of test data, and low test accuracy of the response curve of gas sensitivity characteristics, so as to reduce the influence of gas sensitivity characteristics, Effects of Improving Test Accuracy and Confidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

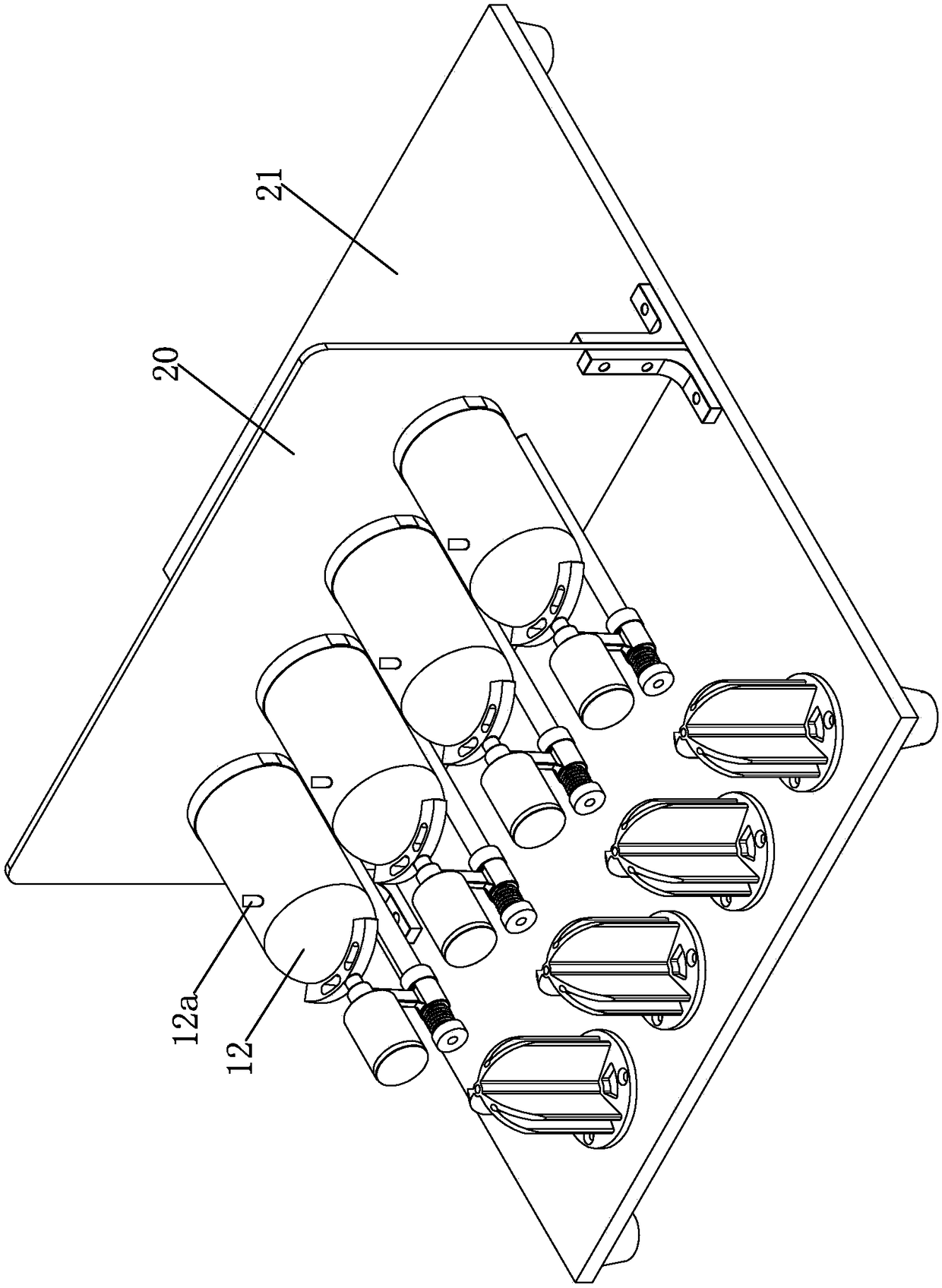

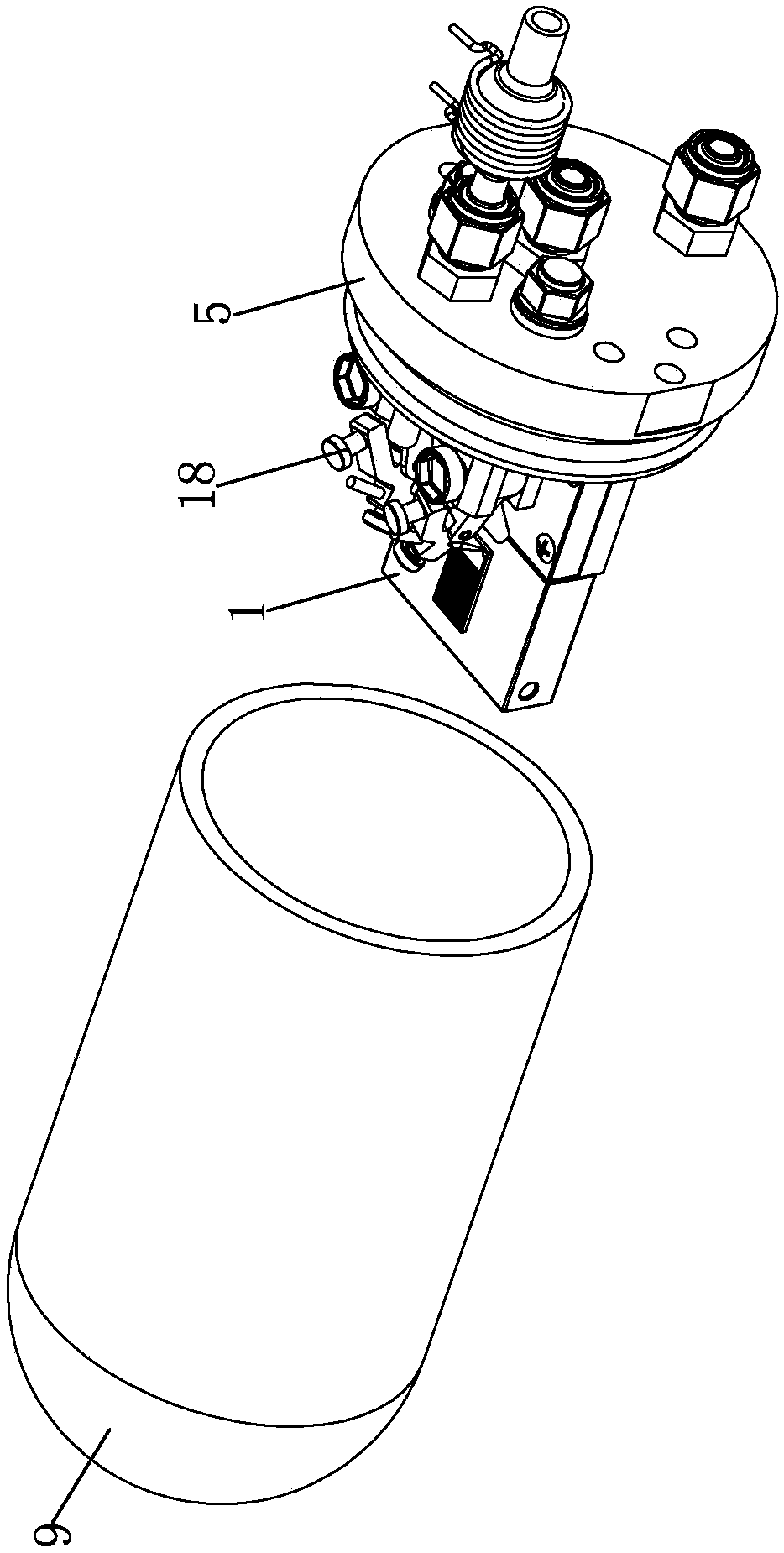

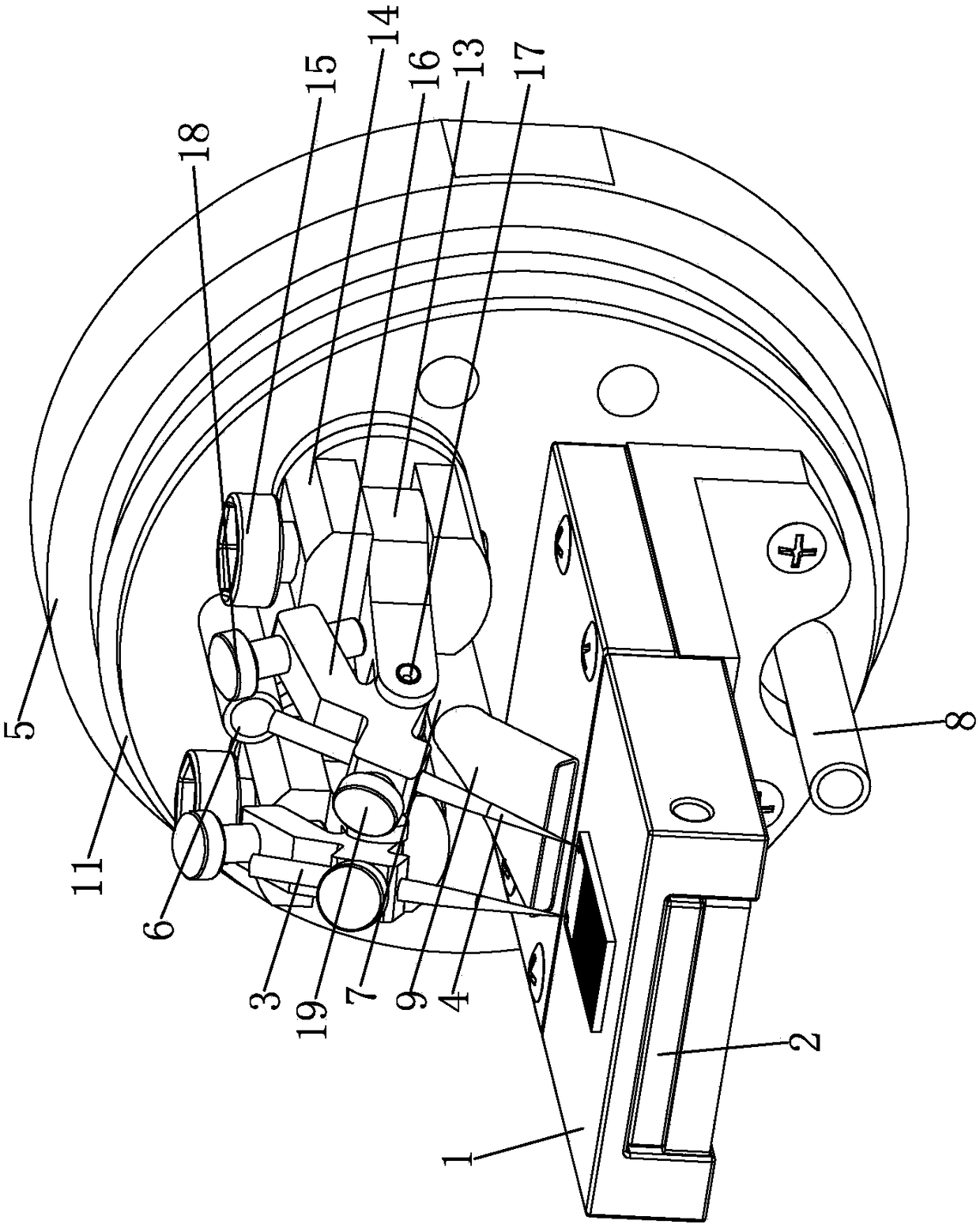

[0021] like figure 1 , 2 As shown in and 3, a gas sensitivity characteristic response curve testing device includes a sample carrier 1 and an inner cover 10, wherein the bottom of the sample carrier 1 is provided with a heating plate 2, and the top surface of the sample carrier 1 is used to carry the gas to be tested. gas-sensitive material, and the heating sheet 2 is a ceramic heating sheet. The first probe 3 and the second probe 4 are existing structures. During the test, these two probes are in contact with the surface of the gas-sensitive material to be tested. These two probes are respectively installed on the corresponding mounting components, and the sample load Both the platform 1 and the adjustment assembly are installed on the flange 5 . The first probe 3 and the second probe 4 are respectively connected to the measuring instrument through corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com