A vibrating walnut picker

A picking machine and vibrating technology, applied in the field of vibrating walnut picking machines, can solve the problems of high labor intensity, low efficiency, frequent safety accidents, etc., and achieve the effects of easy and understandable operation, simple and compact structure, and safe and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

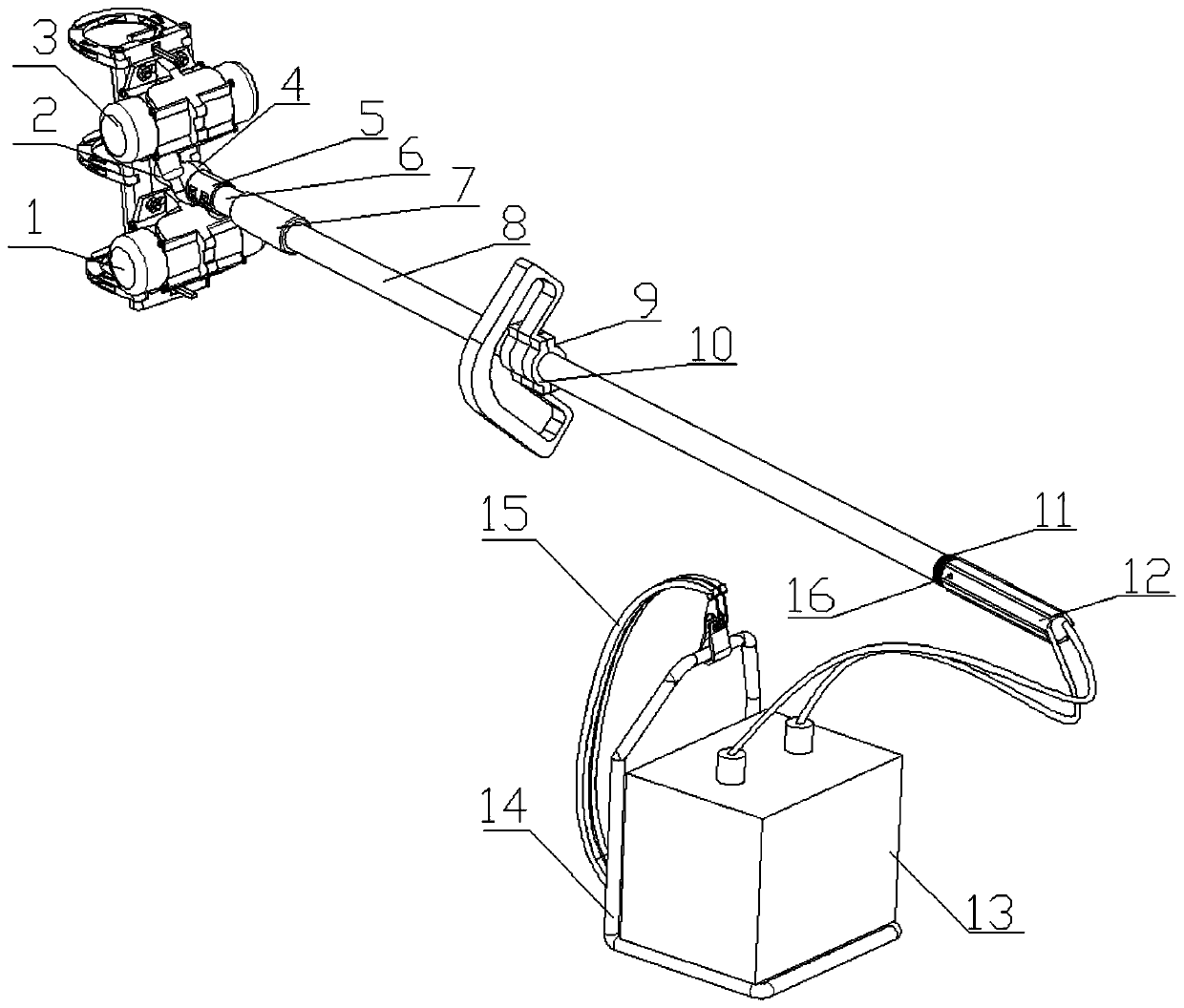

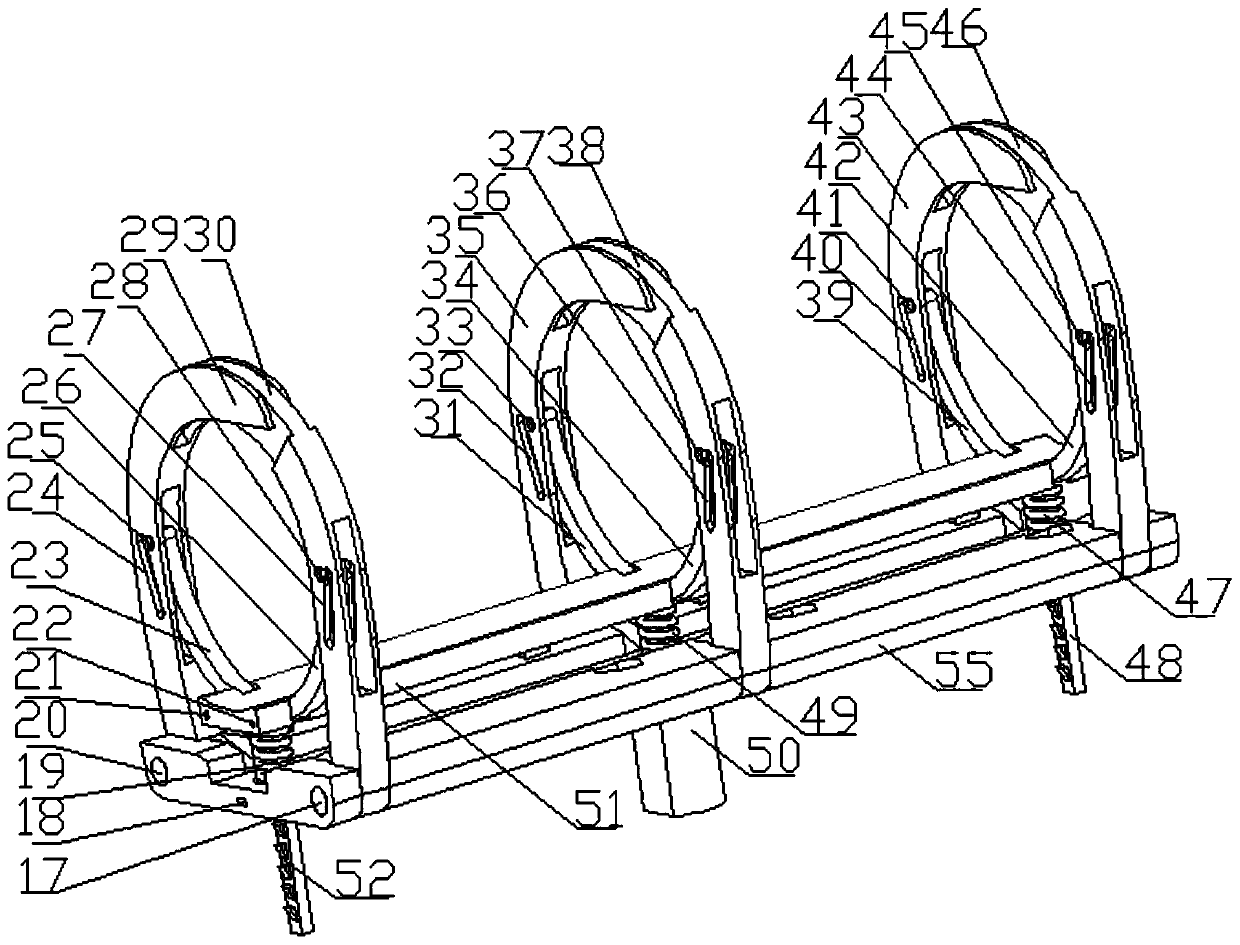

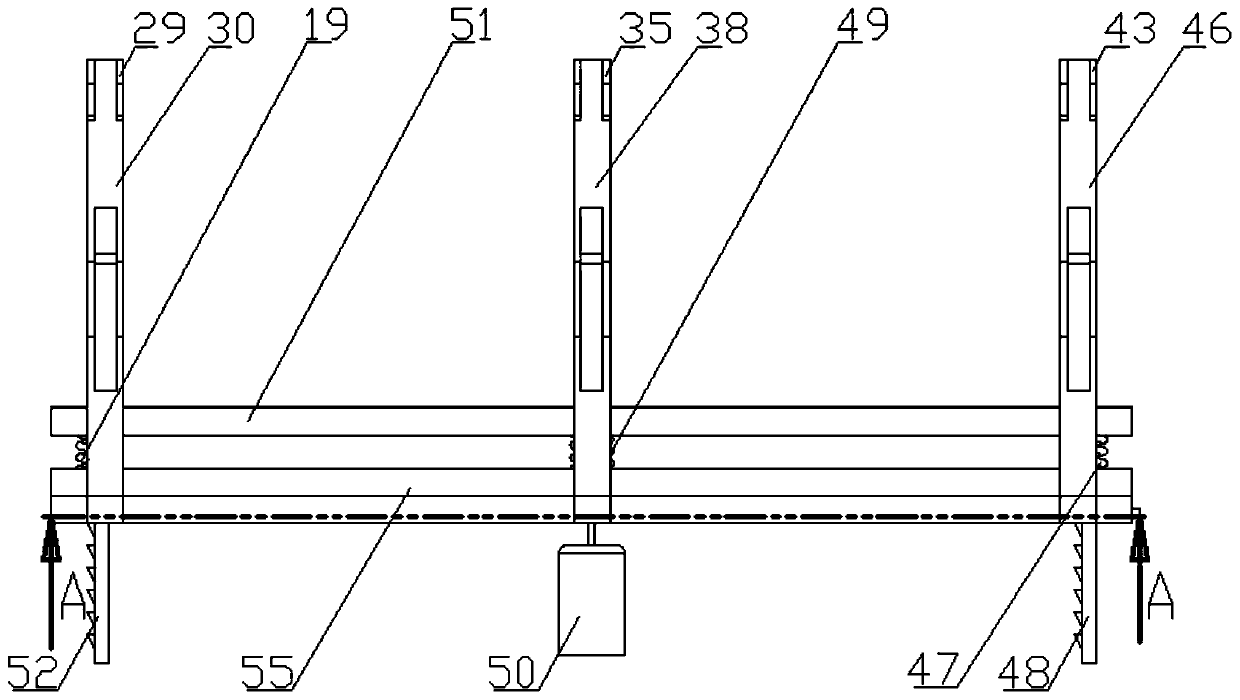

[0038] Embodiment 1: as Figure 1-12 Shown, a kind of vibrating walnut picker, comprises vibrating picking part, hollow supporting connecting rod, power supply, and vibrating picking part, power supply are respectively arranged at the two ends of supporting connecting rod, and wire is arranged in the middle cavity of supporting connecting rod, The vibration source of the vibration picking component is connected to the power supply through wires;

[0039] Vibration picking parts include vibration motor Ⅰ1, vibration motor Ⅱ3, bottom plate 55, push plate 51, claw Ⅰ29, claw Ⅱ30, claw Ⅲ35, claw Ⅳ38, claw Ⅴ43, claw Ⅵ46, pin part Ⅰ20, pin part Ⅱ17, spring Ⅰ19, spring Ⅱ49 , spring Ⅲ47, arc brace Ⅰ23, arc brace Ⅱ26, arc brace Ⅲ31, arc brace Ⅳ34, arc brace Ⅴ39, arc brace Ⅵ42, bolt Ⅲ21, bolt Ⅳ22, card position Sheet 18, miniature spring 53, locking rack I 52, locking rack II 48, joint head 2, motor 50, joint wrapping block I4, joint wrapping block II5;

[0040] Vibration motor Ⅰ1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com