Patents

Literature

36results about How to "Easy to operate and understand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

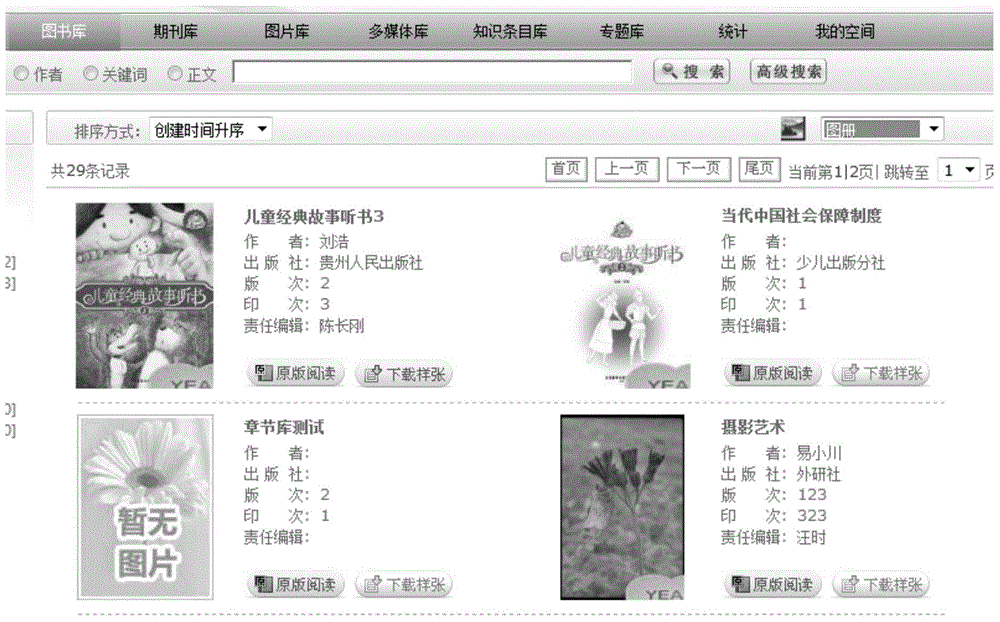

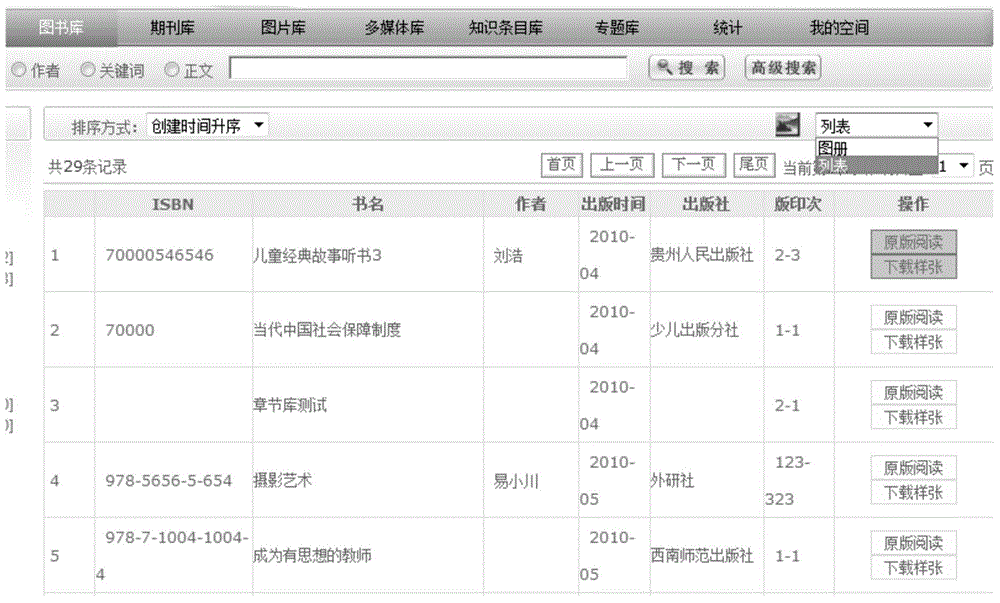

Web page publishing method and system

InactiveCN104424266AFlexible configurationReduce duplication of development workWebsite content managementProgram loading/initiatingWeb pageWeb publishing

The invention discloses a web page publishing method and a web page publishing system, and the method comprises the following steps: sequentially loading various functional zones of a page; to the functional zones demanded to be loaded, reading components and templates configured in the functional zones from a database; processing the corresponding components to obtain data in the functional zones; loading the data into the templates to complete loading of the functional zones; obtaining a complete page after loading all functional zones; publishing the page. According to the method and the system, the page can be flexibly configured so that the repeated development is reduced and the development efficiency is improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

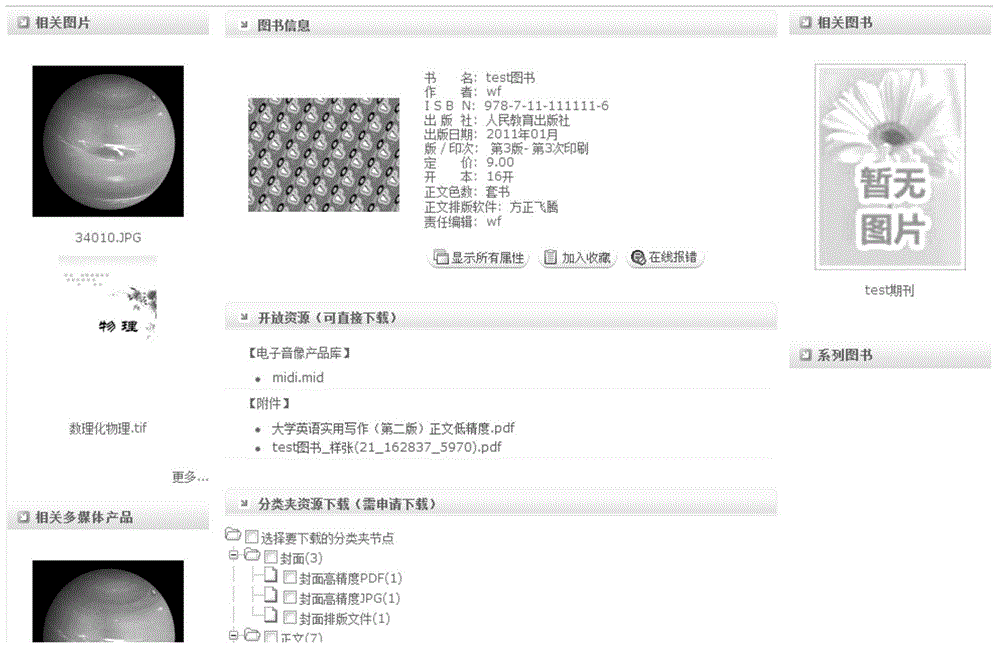

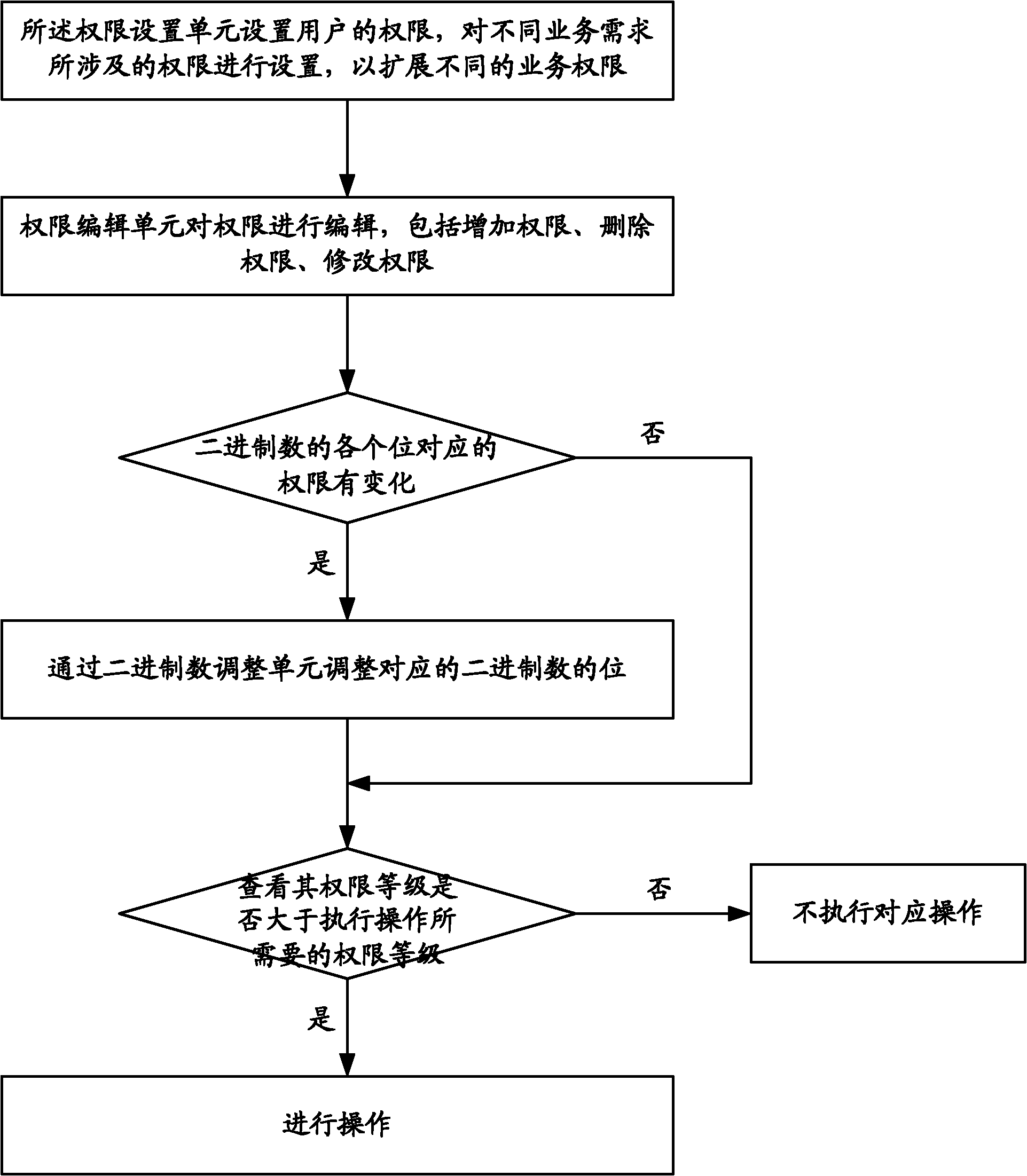

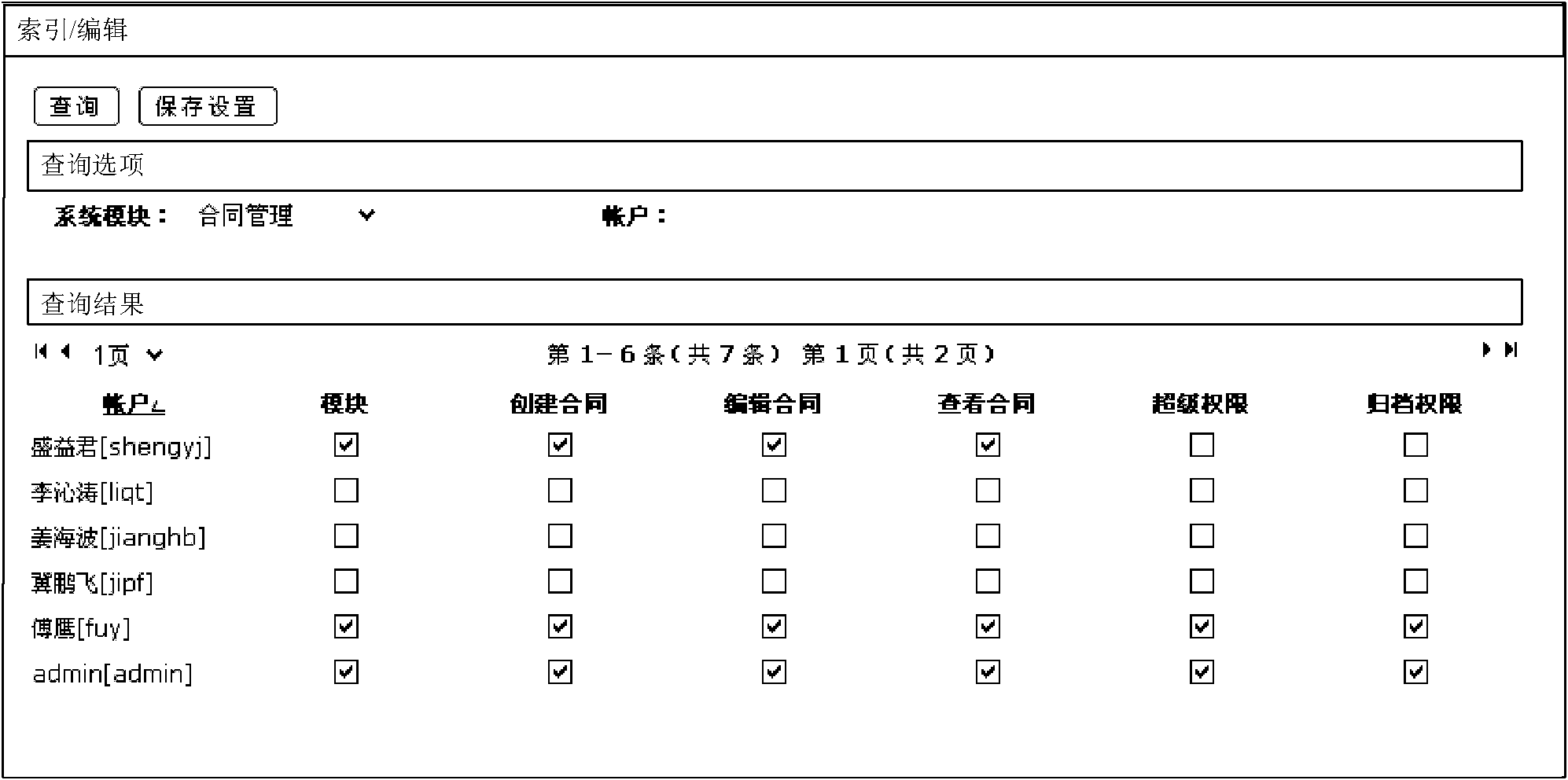

Permission expansion control system and method thereof

InactiveCN101894231AIncrease permissionsImprove scalabilityDigital data authenticationControl systemBusiness requirements

The invention discloses a permission expansion control system and a method thereof. The system is composed of a permission setting unit and a permission editing unit, wherein the permission setting unit is used for setting user permissions and setting permissions relative to different business requirements so as to expand different business permissions; and the permission editing unit is used for editing permissions in the system, including permission addition, permission deletion and permission alteration. The permission expansion control system and the method thereof disclosed by the invention can conveniently and rapidly expand user permissions, can add, delete and alter permissions, and is easy for operation, understanding and expansion. The permission control method in the invention is realized by adopting the principle that forward carry increment is performed from a low permission bit to a high permission bit, namely, permission bit distribution can be performed based on the expansion principle from a low position to a high position according to new application operation, thus realizing infinite expansion of customized permissions.

Owner:上海三零卫士信息安全有限公司

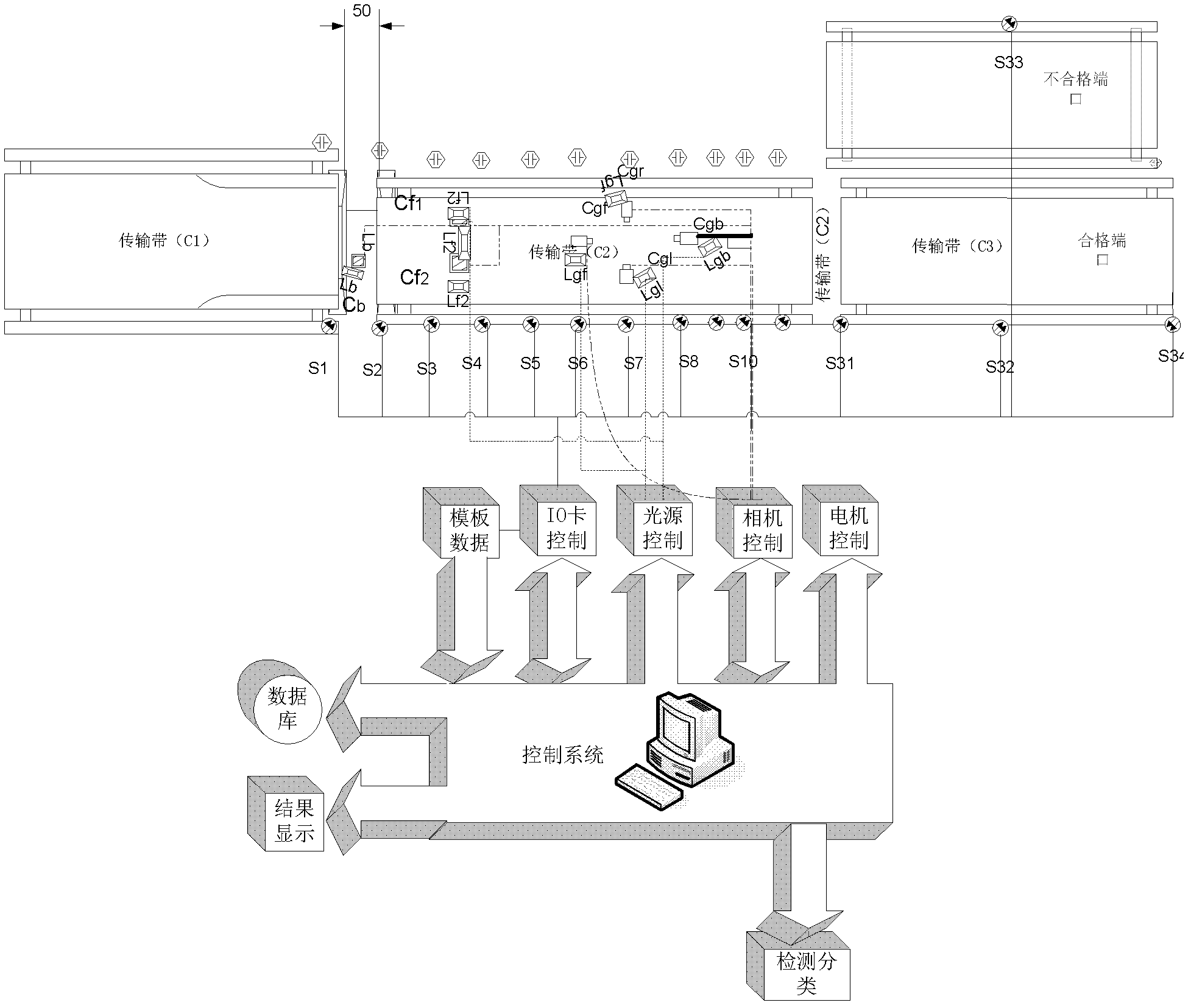

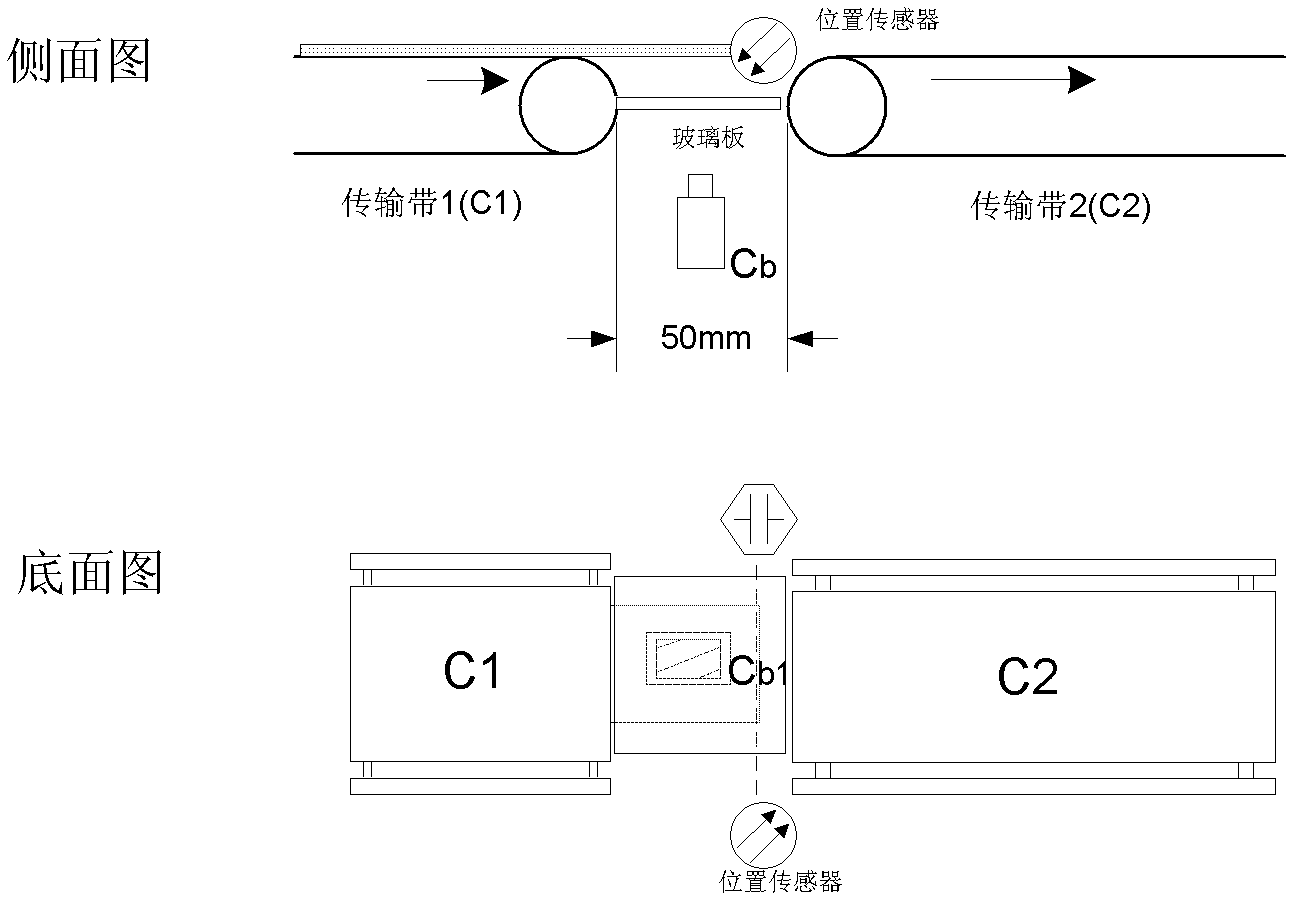

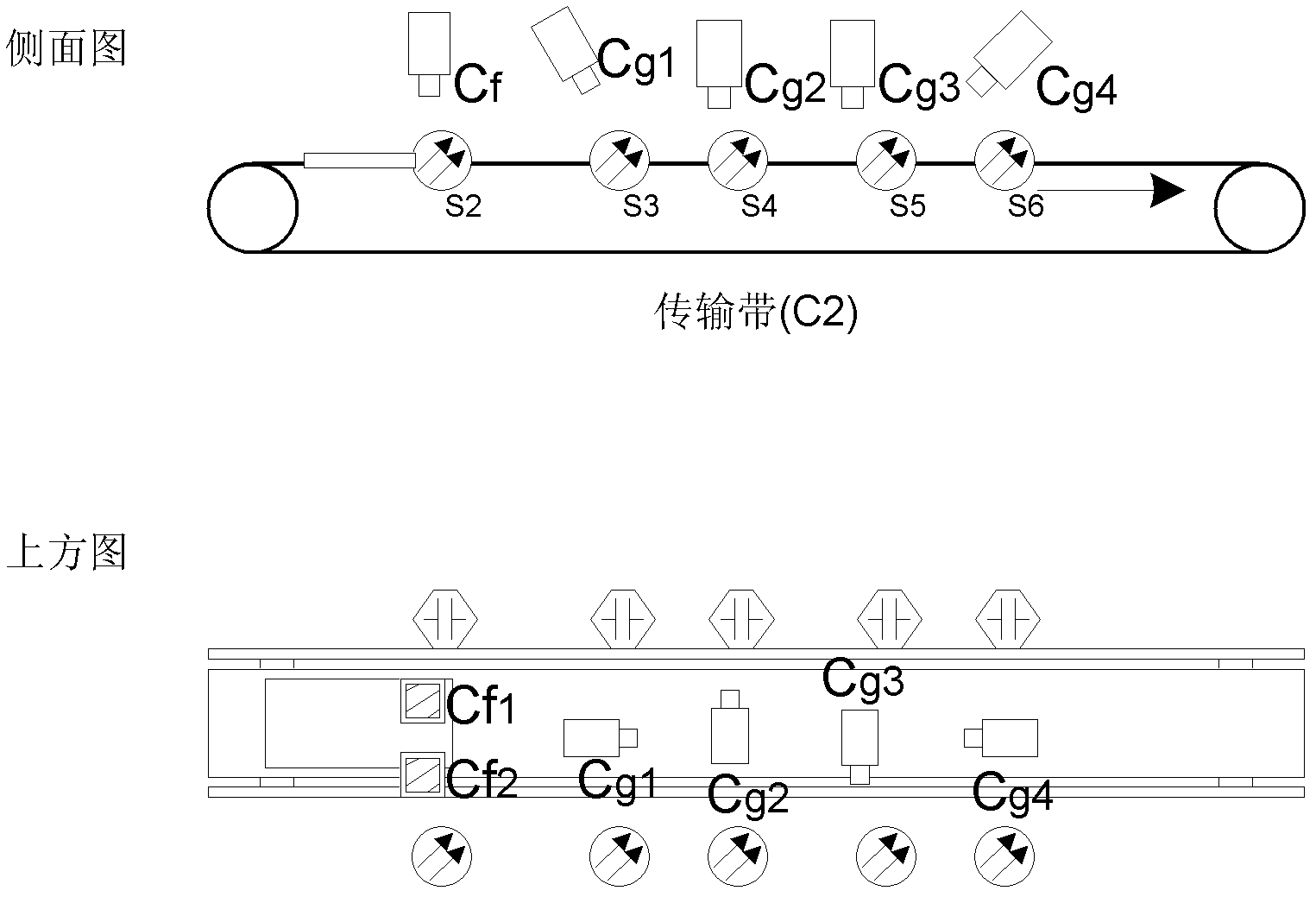

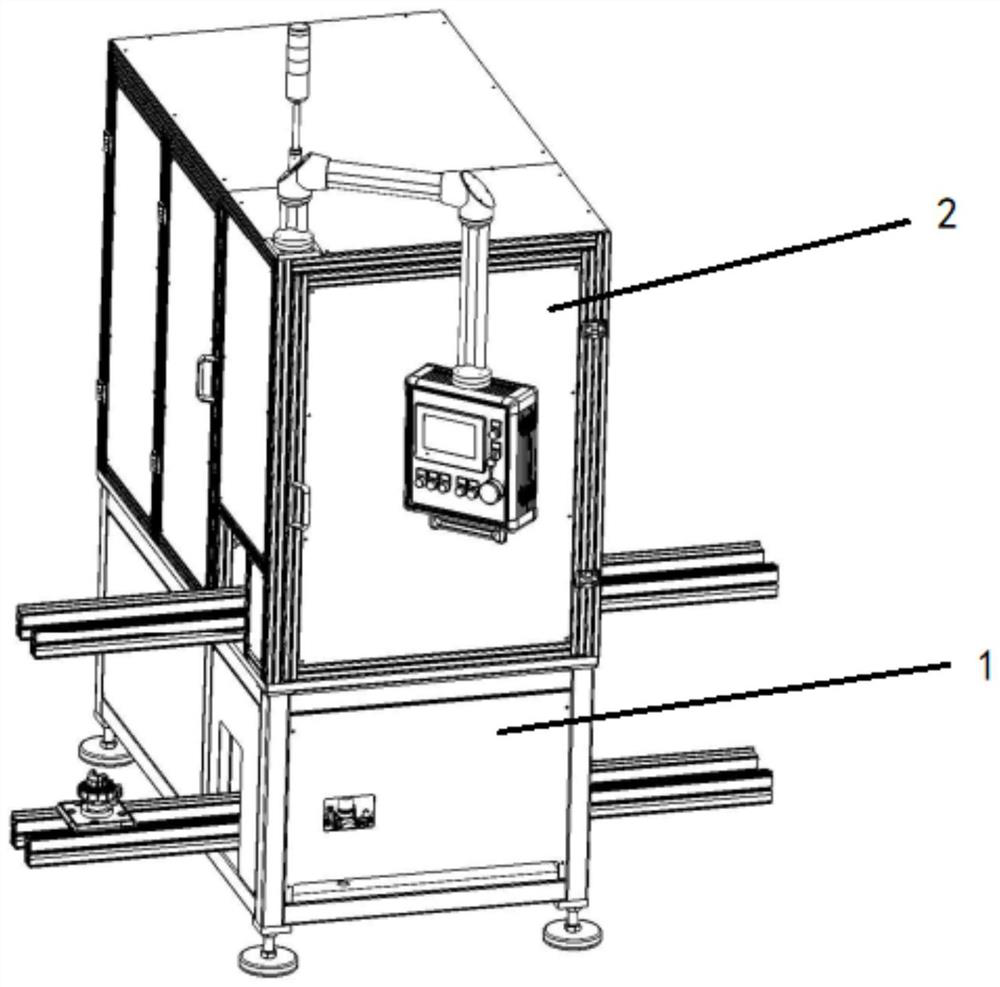

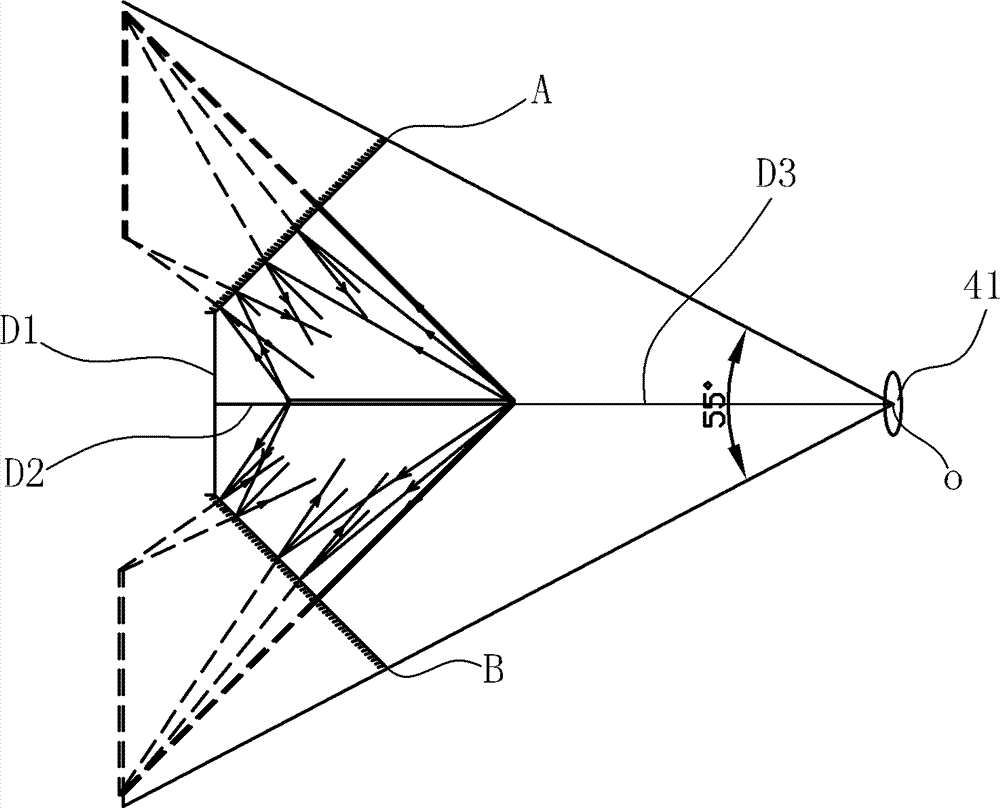

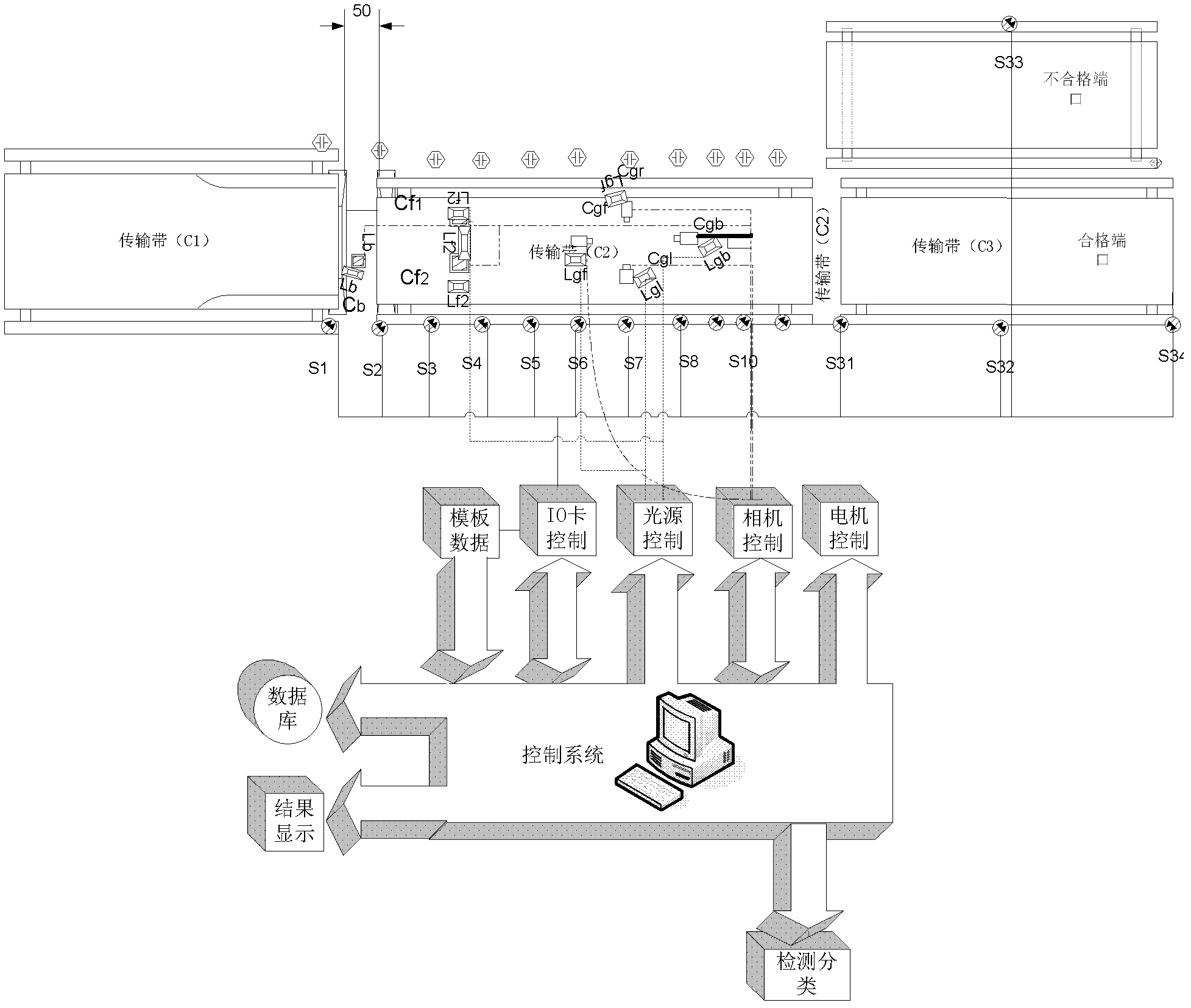

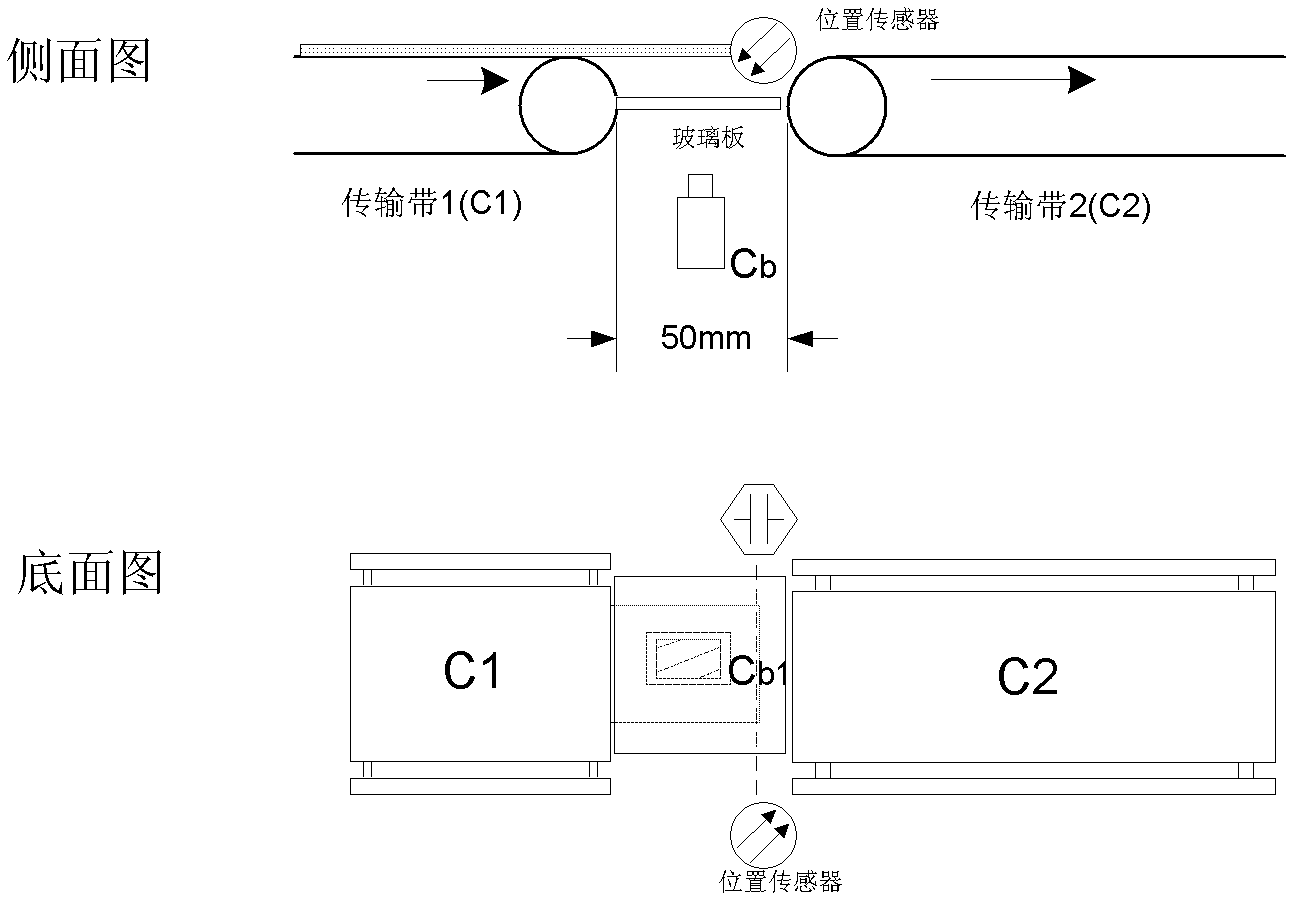

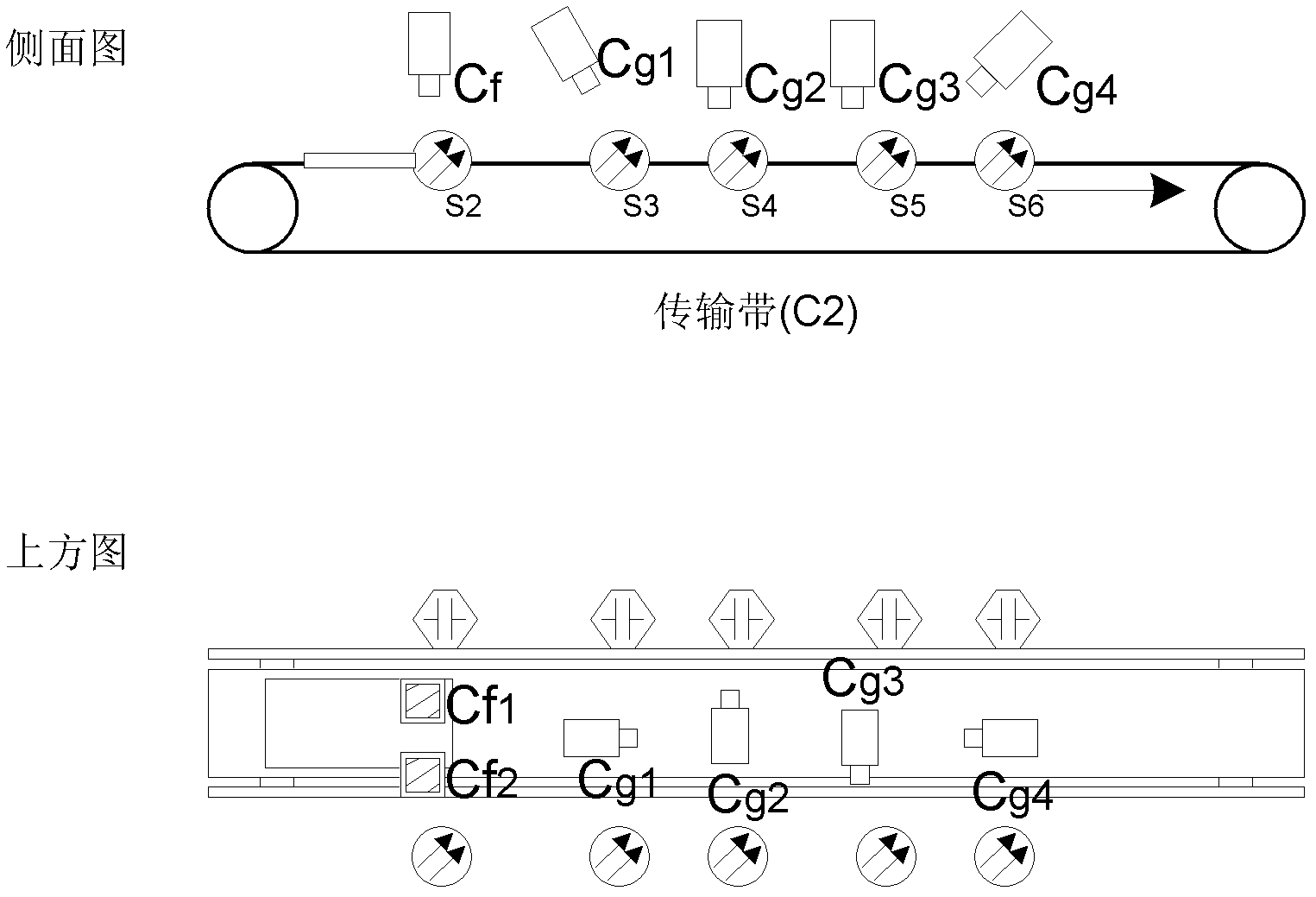

Detection device and method for appearance and assembly of electric paper book based on machine vision

ActiveCN102353683AEnsure clarity and completenessGuaranteed infallibilityOptically investigating flaws/contaminationMachine visionEconomic benefits

The invention discloses a detection device for apparent defects and an assembly of an electric paper book. Three-section type online detection is adopted in the detection process of the device and back side detection of a product is carried out in a gap of the sections; and detection for the requirements on pollution, scratches, missing parts, assembly errors and the like is carried out by detection software based on a pattern recognition algorithm. According to the electric paper book detection device defined by the invention, the position of the electric paper book is transmitted to a camera through a sensor to trigger and collect images; and then background analysis is carried out according to the collected images. The design of the device guarantees an automatic flow of the detection process and the detection state can be monitored; and then products can be processed by a qualified / unqualified classification according to a detection result. By using the electric paper book detection device disclosed by the invention, objective and accurate detection can be obtained. In addition, the operation of the device is convenient and easy to understand and the defects of the electric paper book can be accurately detected without professional skills, so that careless mistakes caused by the judgment of artificial subjective factors can be effectively prevented and the detection deviceis good for improving the work efficiency of staff and the economic benefits of enterprises.

Owner:苏州优纳科技有限公司

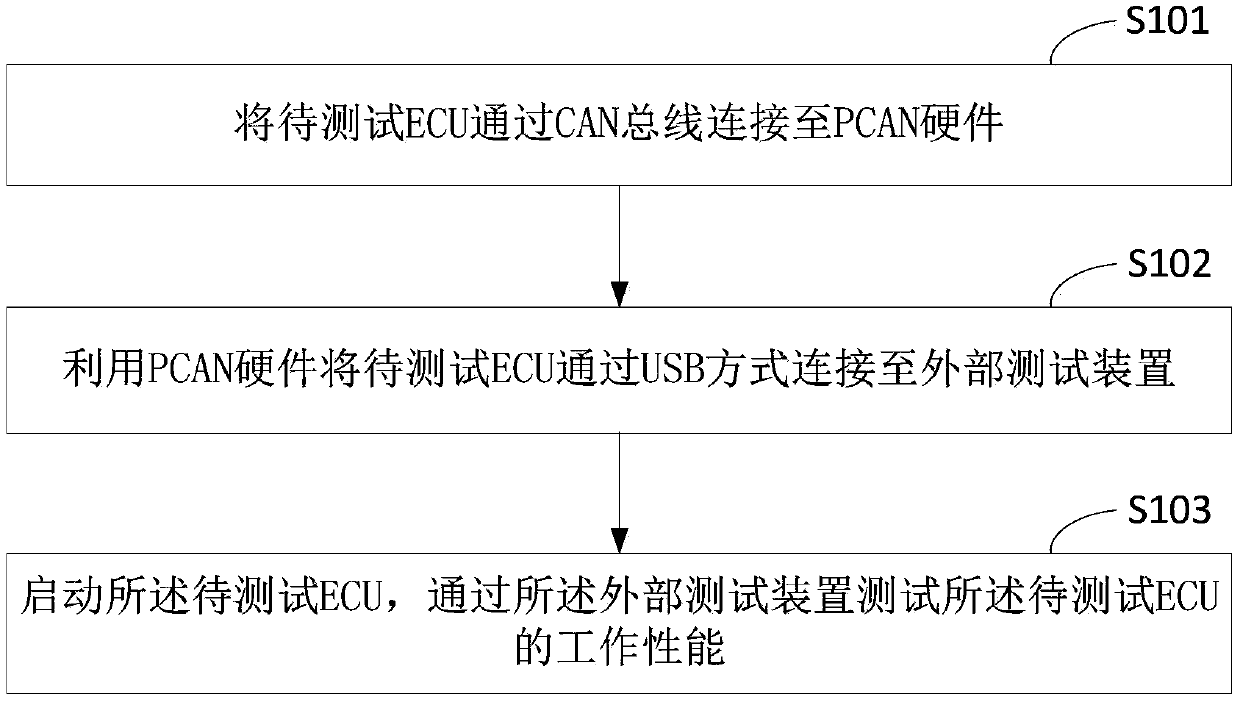

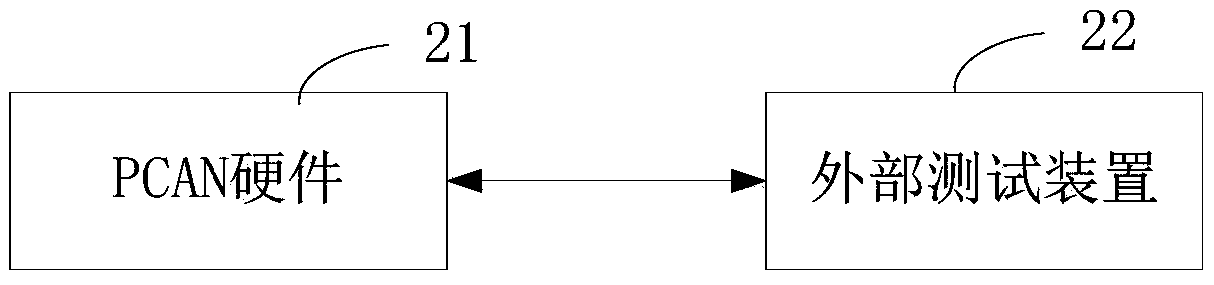

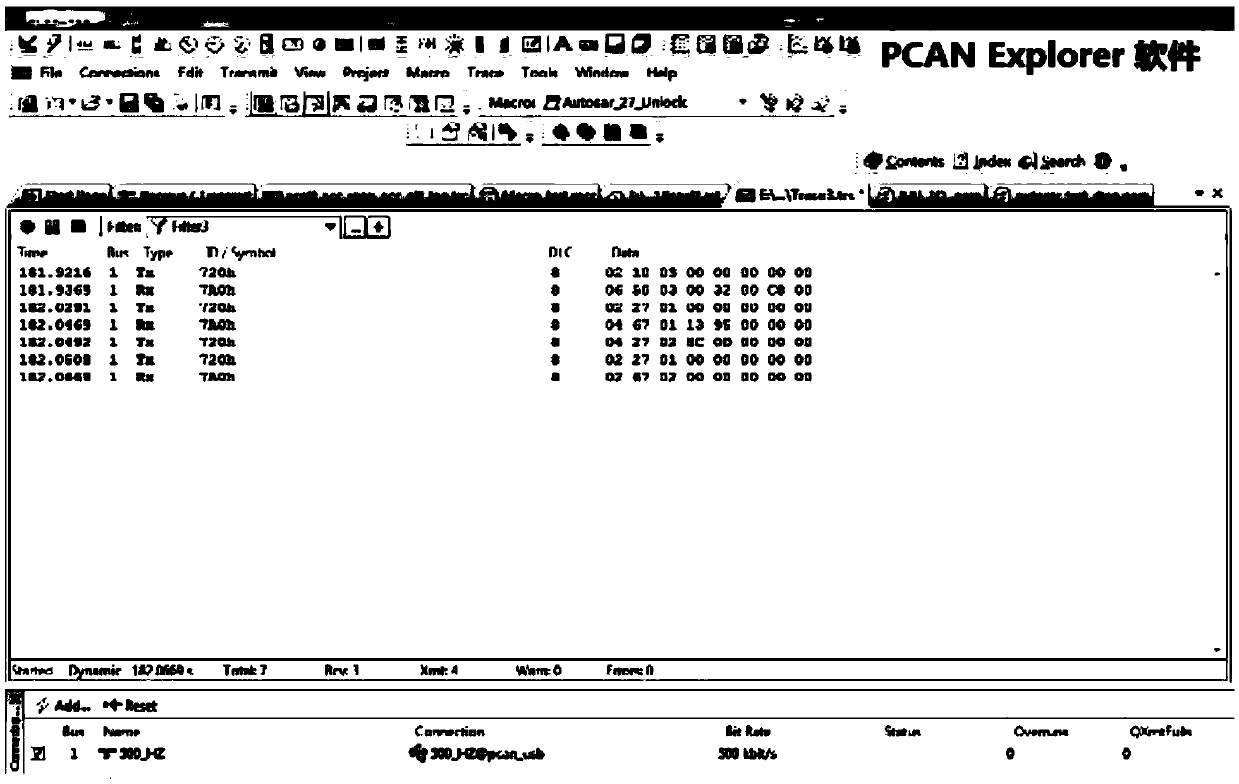

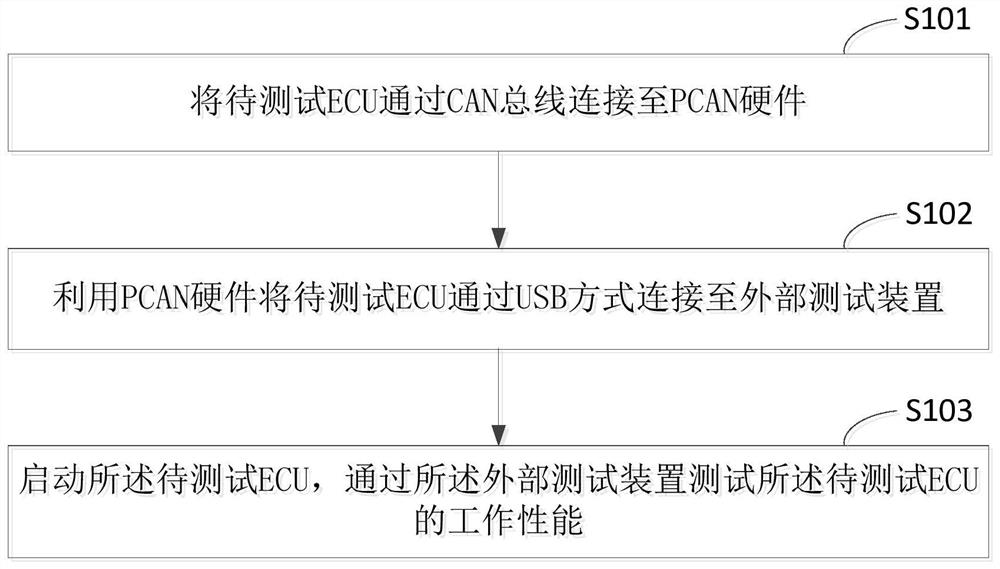

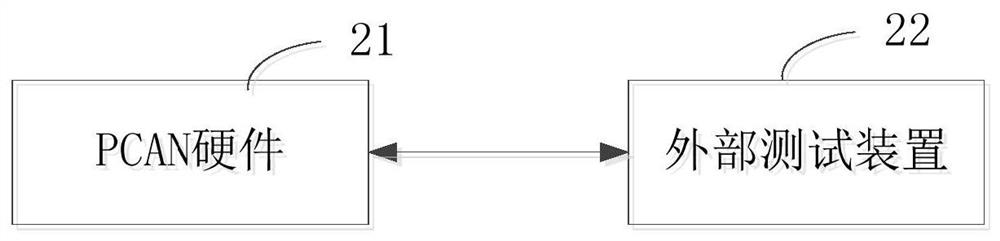

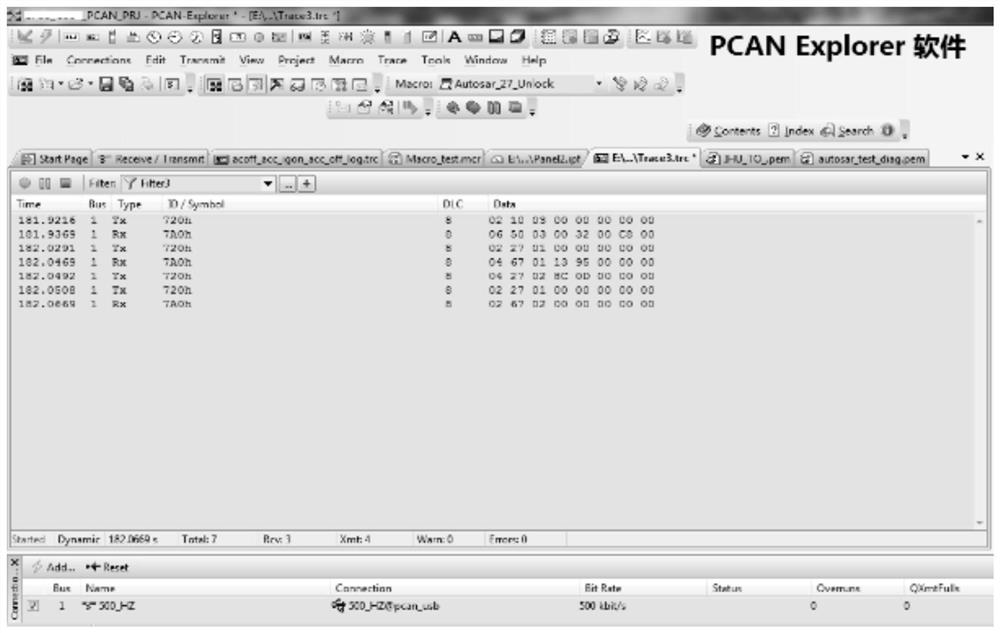

CAN bus test system and CAN bus test method based on UDS

ActiveCN110233768AEasy to set upEasy to operate and understandElectric testing/monitoringBus networksEngineeringTest fixture

The invention relates to the technical field of testing, and provides a CAN bus test system and a CAN bus test method based on a UDS. An ECU to be tested is connected to PCAN hardware through a CAN bus, the ECU to be tested is connected to an external testing device through the PCAN hardware in a USB mode, the ECU to be tested is started, and the working performance of the ECU to be tested is tested through the external testing device. In this way, the use of high-cost German Vector software in cooperation with a canoe hardware test system can be avoided, the test cost is effectively reduced,the test effect is accurate, the success rate is high, the test system is simple to erect, the operation is convenient and easy to understand, meanwhile, the same test function as that of the German Vector software matched canoe hardware test system can be realized, and the working performance of a product is ensured.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

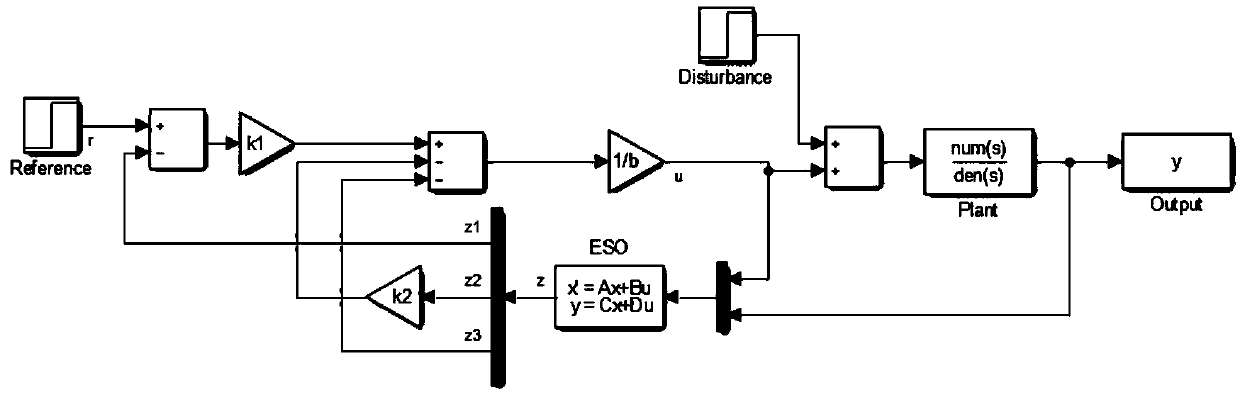

Parameter robust setting method for linear active disturbance rejection control (LADRC)

InactiveCN108919643AGood control effectEasy to operateAdaptive controlActive disturbance rejection controlOperability

The invention relates to the technical field of control, and provides a parameter robust setting method for a linear active disturbance rejection control (LADRC). The method employs a second-order LADRC, a setting formula of controller parameters b, Omega c and Omega o, which conform to robust performance constraint, is obtained by numerical value simulation with regards to a first order plus deadtime (FOPDT), and the method is promoted to an ordinary industrial controlled object. The LADRC set by the method can obtain relatively good control performance, is high in robustness and relativelygood in disturbance resistance; and moreover, an adjustable factor is provided, slight adjustment can be performed according to requirements of control performance of different objects, the model applicability is relatively high, and the operability is good.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

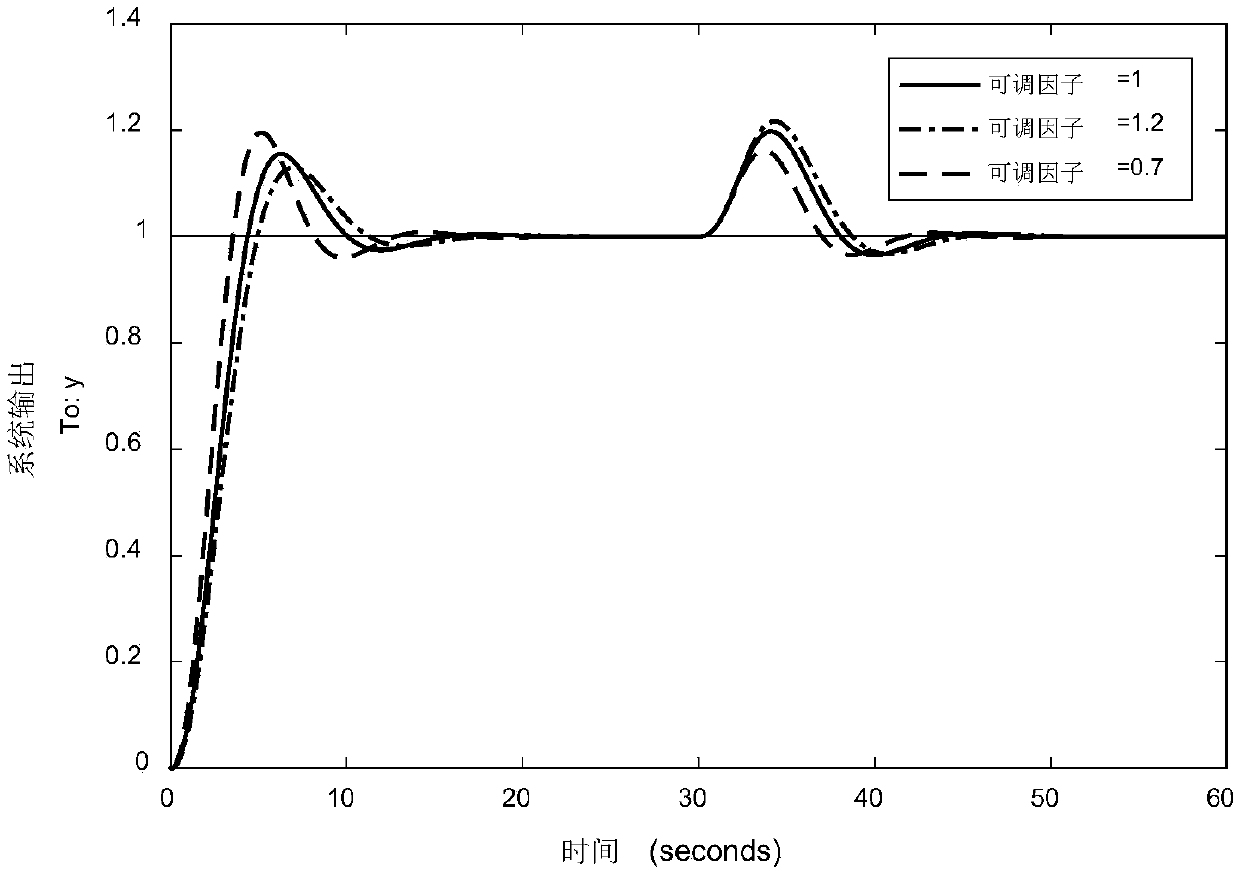

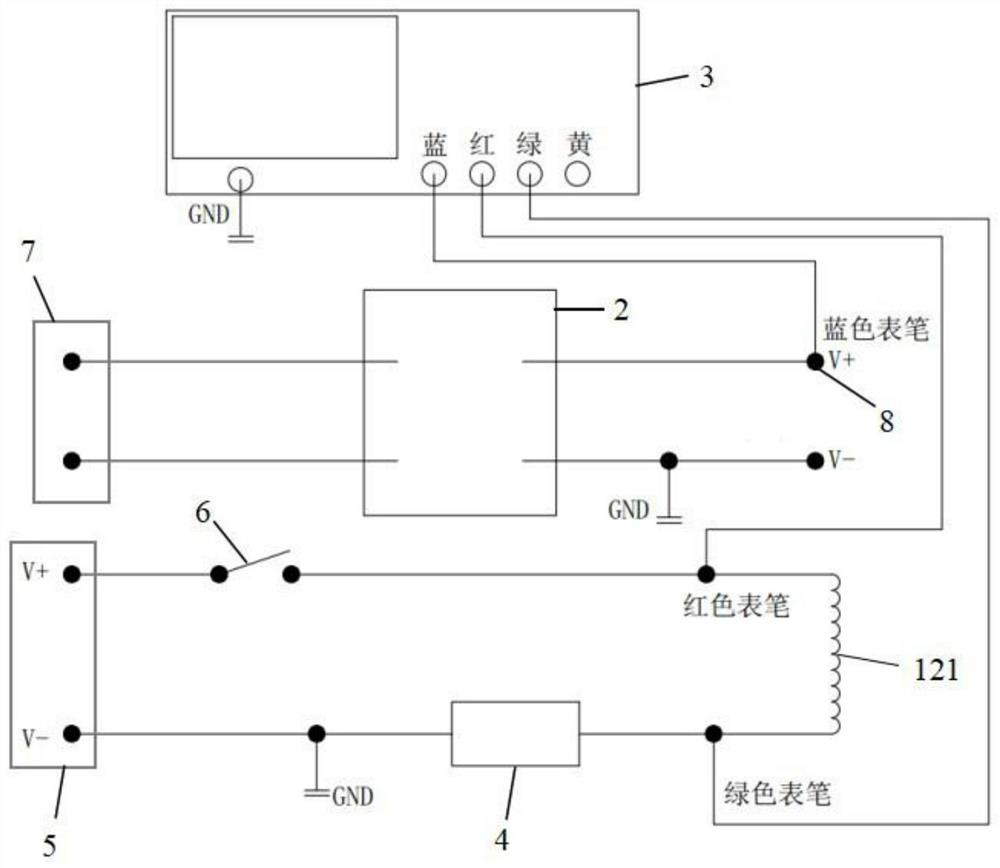

Electromagnet response tester

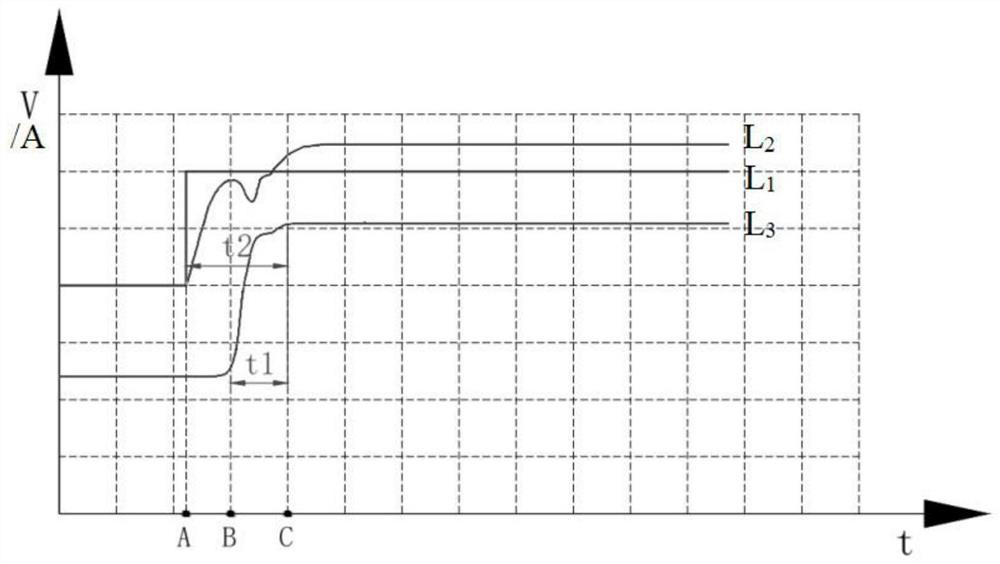

InactiveCN112014672AResponse is true and accurateThe response is clear at a glanceElectrical testingTester deviceMechanical engineering

The invention provides an electromagnet response tester which comprises a hydraulic electromagnetic valve, an oscilloscope and a laser displacement sensor, a through hole is formed in an end cover ofthe valve body of the hydraulic electromagnetic valve, and laser emitted by the laser displacement sensor can be emitted into the valve body through the through hole and used for sensing the positionof a valve element of the hydraulic electromagnetic valve; the laser displacement sensor is electrically connected with the oscilloscope and used for collecting output voltage capable of reflecting the displacement of the valve element. Two ends of a coil of the electromagnet are connected with an electromagnet power supply, a time relay is connected in series between the coil and the electromagnet power supply, and on-off of the electromagnet is controlled through the time relay; the two ends of the coil of the electromagnet are connected with the oscilloscope in parallel and used for collecting the voltage at the two ends of the coil of the electromagnet and the current passing through the electromagnet. According to the invention, the voltage and current of the coil and the displacementcurve of the valve element are displayed on the oscilloscope, and the accurate on-off response time of the electromagnet can be obtained by analyzing the curve, so that the performance of the electromagnet is judged.

Owner:安阳凯地磁力科技股份有限公司

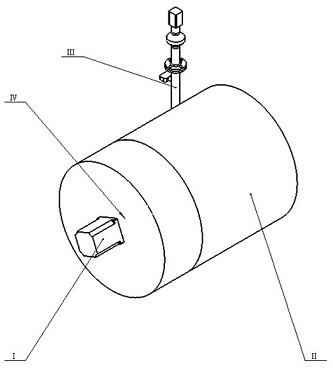

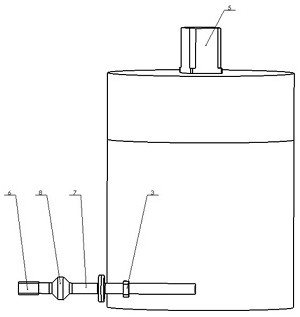

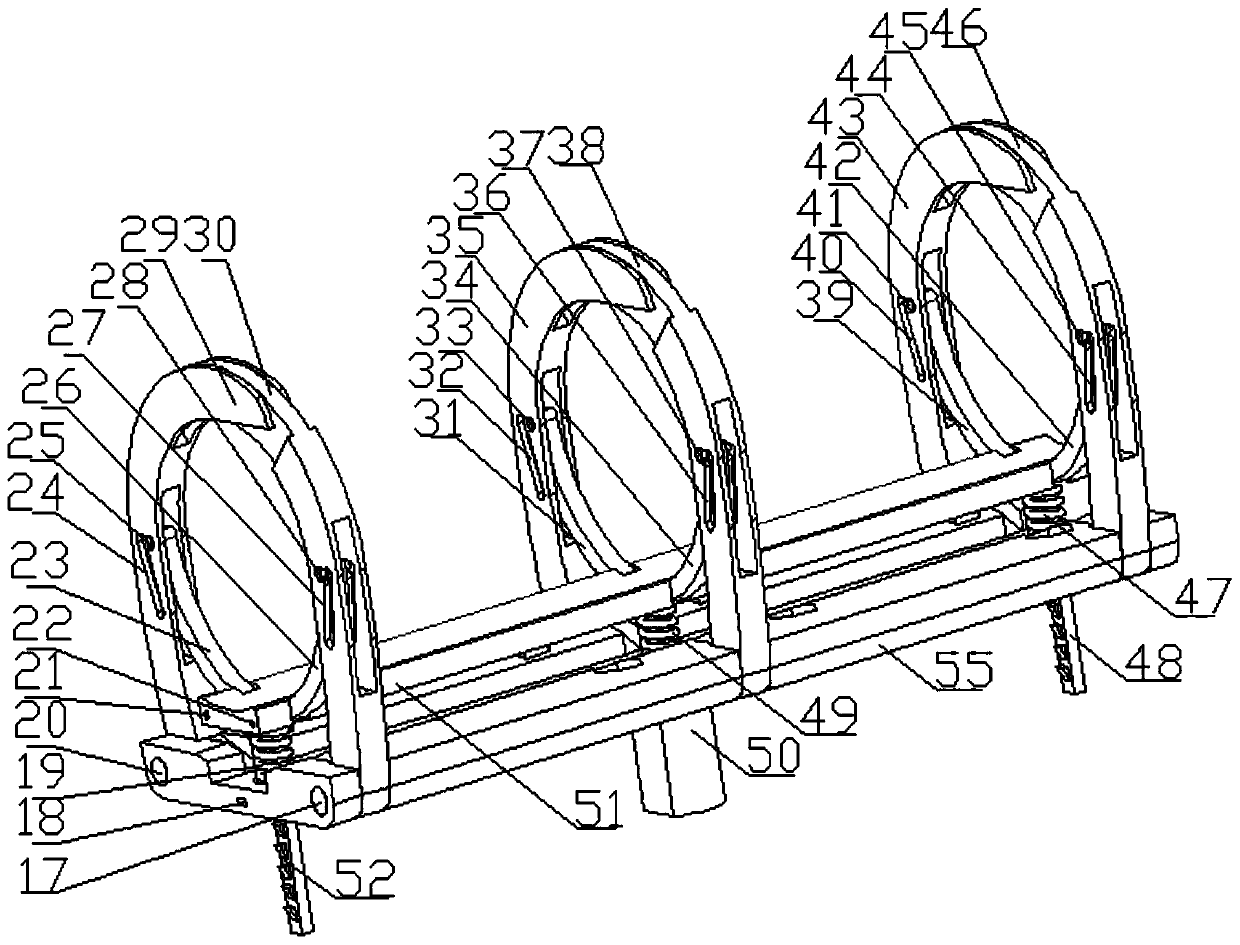

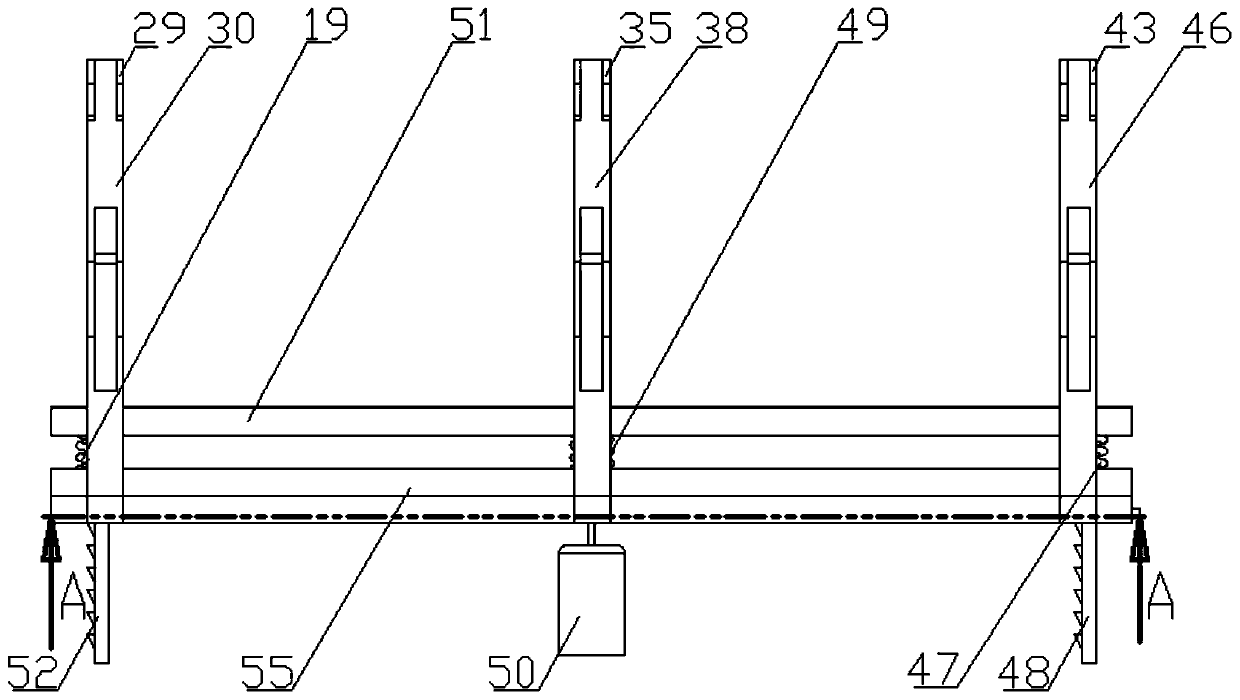

Finishing machining air pressure abrasive pool device for complex curved surface workpieces

InactiveCN111890216AIncrease profitPrevents erosion and wearEdge grinding machinesPolishing machinesAir filtrationAir compression

The invention relates to a design and operation method of a finishing machining air pressure abrasive pool device for complex curved surface workpieces, and belongs to the field of precision workpiecesurface finishing machining. The device is composed of a cylindrical cylinder body, an air compression device, an air transmission device and a workpiece machining device, wherein the air compressiondevice filters and heats sucked air to a constant temperature, the constant-temperature air passes through the air pressurizing transmission device, a high-pressure spray head sprays the constant-temperature air into the cylindrical cylinder body at a high speed and pushes fine particles in the cylindrical cylinder body to form abrasive flow, and a workpiece machining device driven by a high-speed motor and the abrasive flow form relative motion to carry out finishing machining on the complex curved surface workpieces. According to the device, a plurality of gears can be additionally arrangedon the workpiece machining device, so that the machining efficiency is improved; the device is high in adaptability, and the air transmission device can regulate and control the air speed and pressure of the air; the size of the abrasive particles in the cylindrical cylinder body can be adjusted according to the requirement of the workpieces on the finishing environment; and the device is high infinishing efficiency, capable of machining the plurality of workpieces at the same time, wide in application range, capable of finishing the complex curved surface workpieces and carrying out operations such as removing flashes and burrs on the complex curved surfaces, and has the advantages of being simple and convenient in operation, simple in structure, safe and reliable.

Owner:SHANDONG UNIV OF TECH

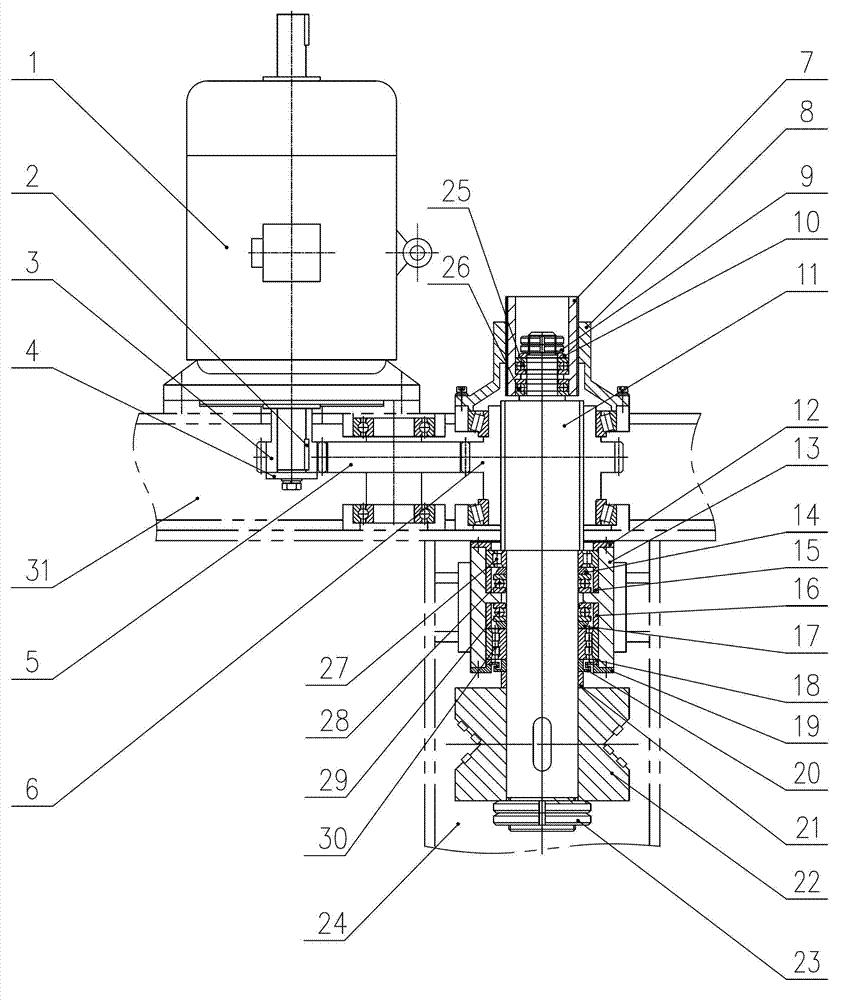

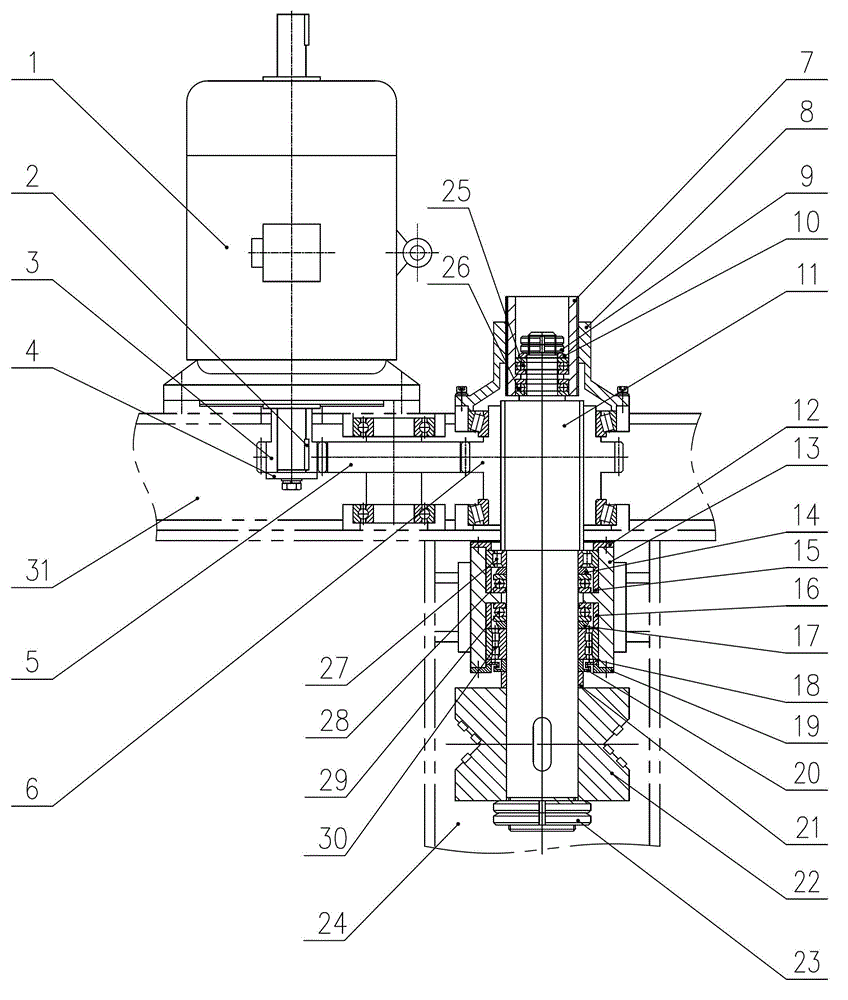

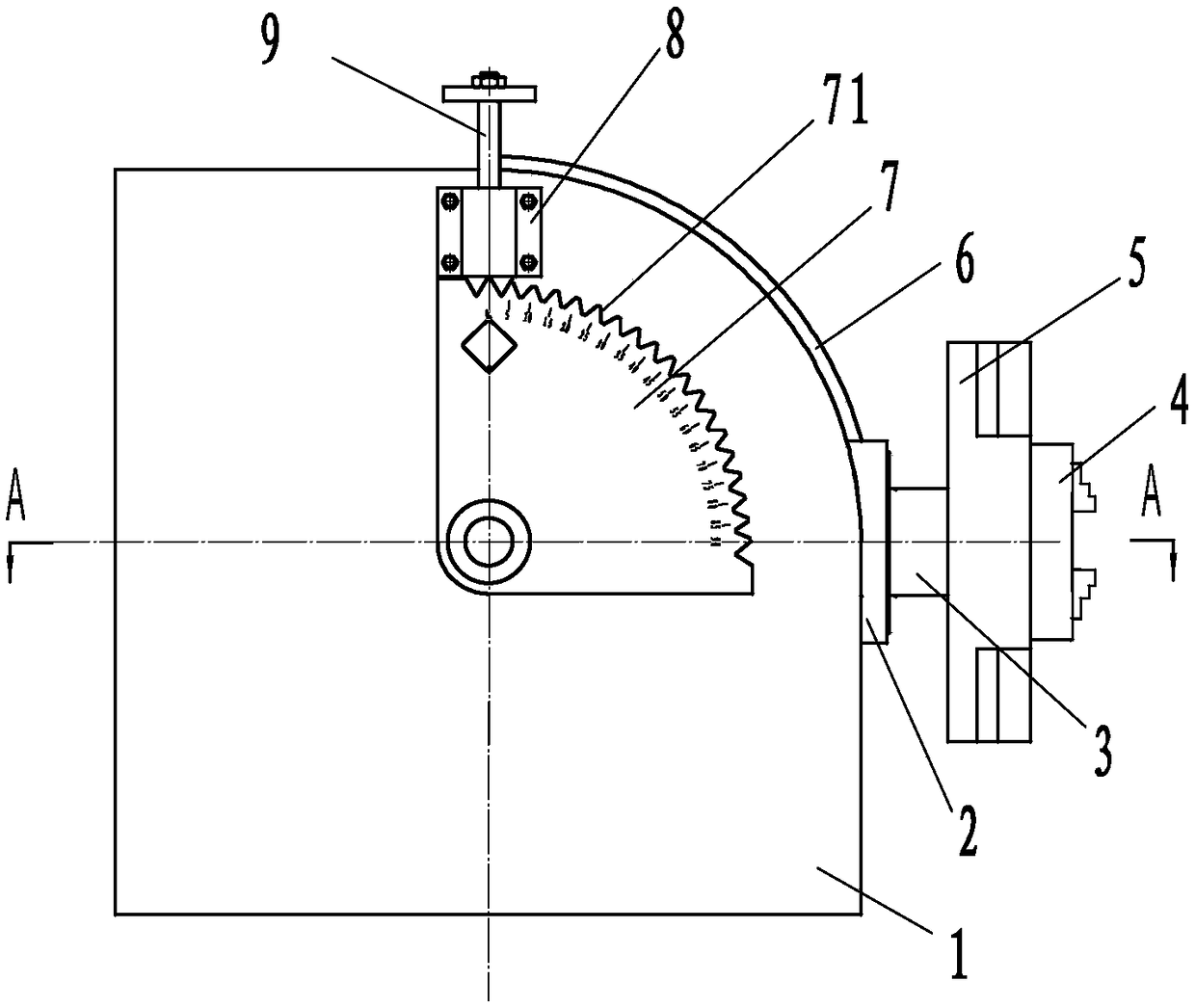

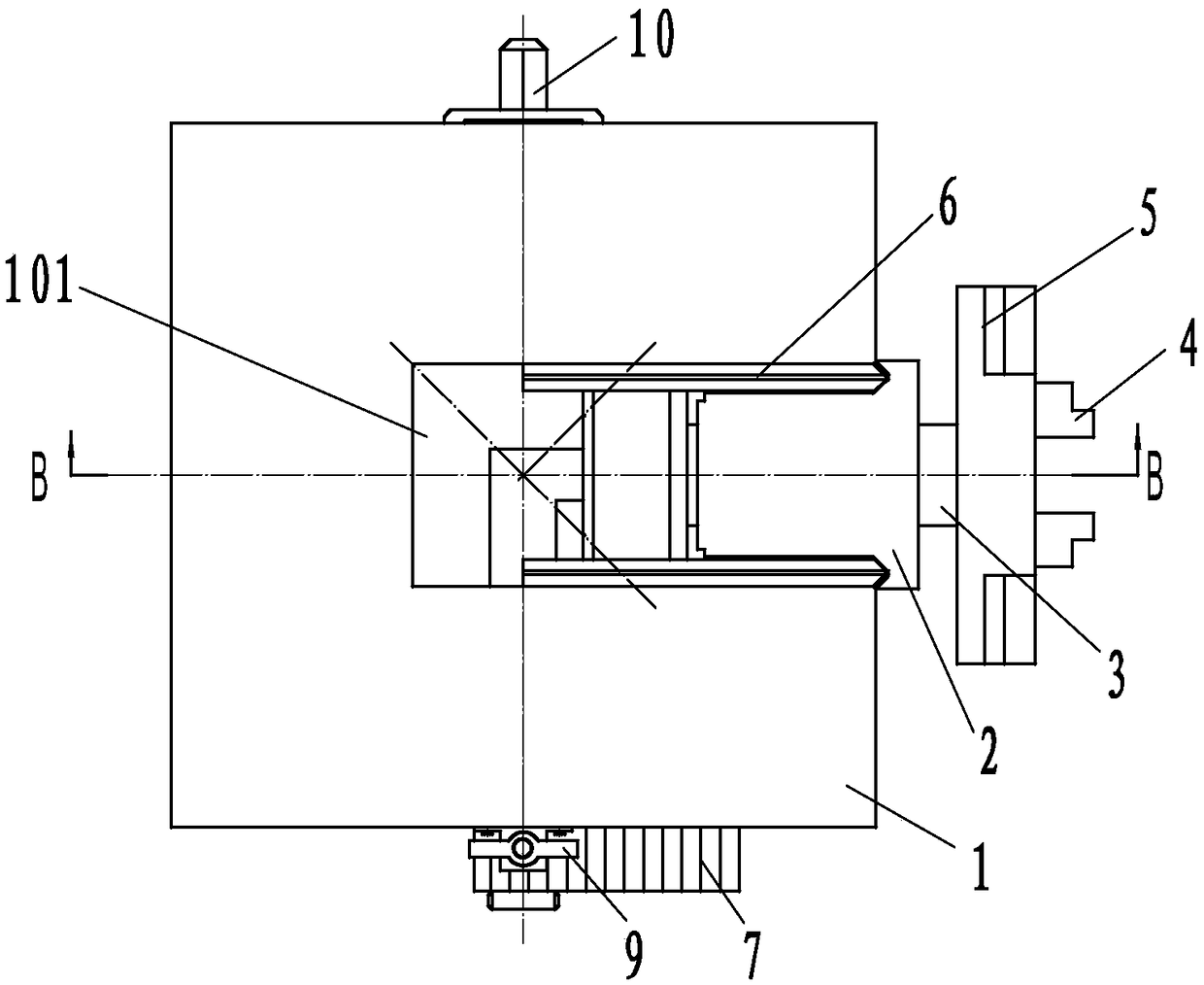

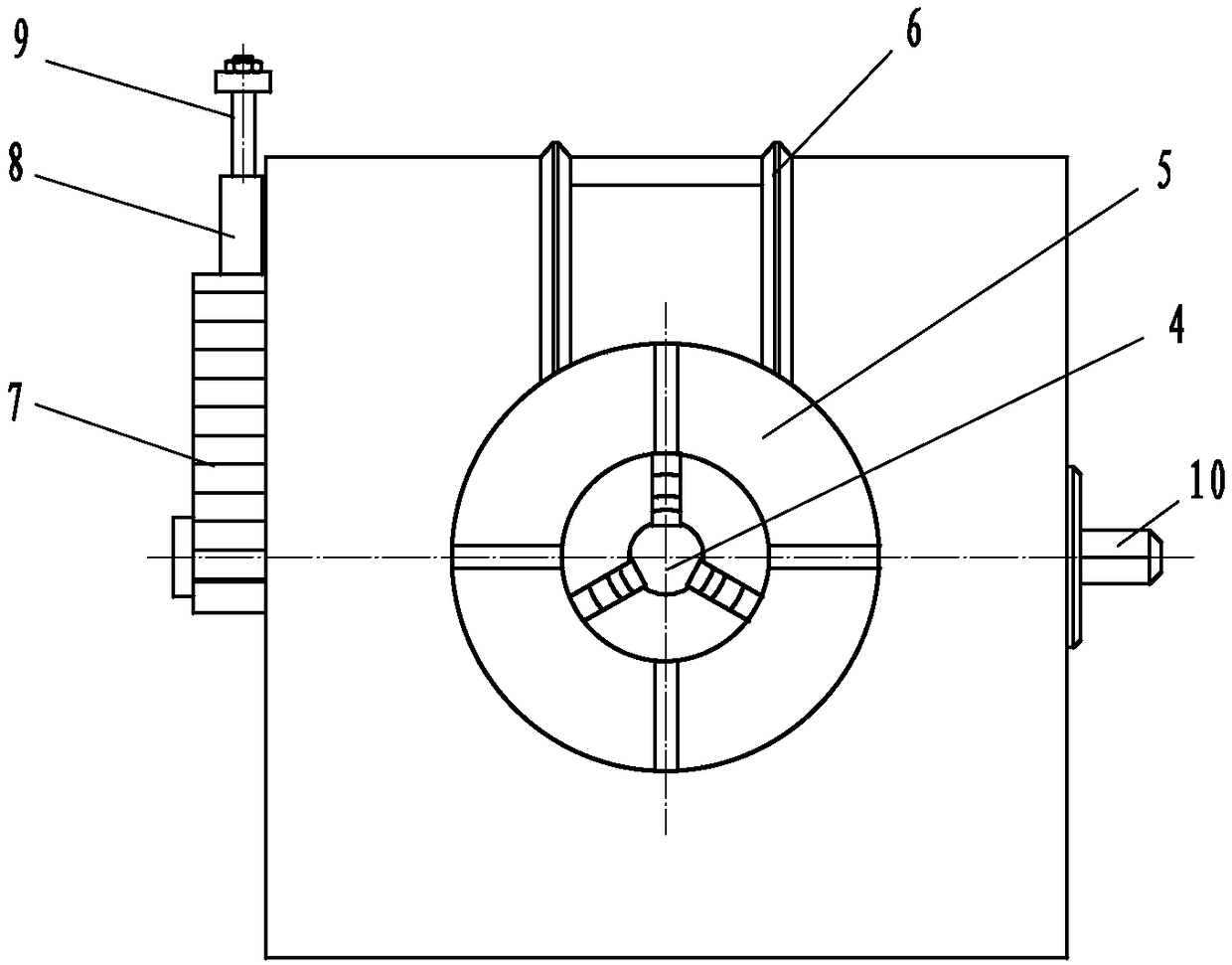

Steel plate double groove edge milling machine milling head driving and vertical fine adjustment mechanism

ActiveCN102922028AAdjustable thicknessReduce noiseMilling equipment detailsDriving apparatusMilling cutterGear wheel

The invention relates to a steel plate double groove edge milling machine milling head driving and vertical fine adjustment mechanism. The mechanism is characterized in that the mechanism comprises a speed reducer, a flat key, a driving gear, a gear end cover, a transition gear, a driven gear, a milling spindle, a milling head and a large circle nut. The steel plate double groove edge milling machine milling head driving and vertical fine adjustment mechanism has the advantages that the structure is simple, compact and reasonable, when the displacement of the milling head is adjusted, an operator can merely rotate an adjusting screw nut at the top of the milling spindle, the groove thickness can be adjusted, the angle and direction of the milling head can be selected according to different requirements for groove, the groove noise is low, a fully mechanical cutting and milling type machining mode is utilized, the thermal deformation and uneven surfaces are absent, the groove surface is smooth and clean after machined, the secondary polishing is not required, the mechanism is convenient to operate and easy to grasp, the mechanism is suitable for various working environments, and the labor intensity of workers is reduced.

Owner:WUXI HUALIAN SCI & TECH GROUP

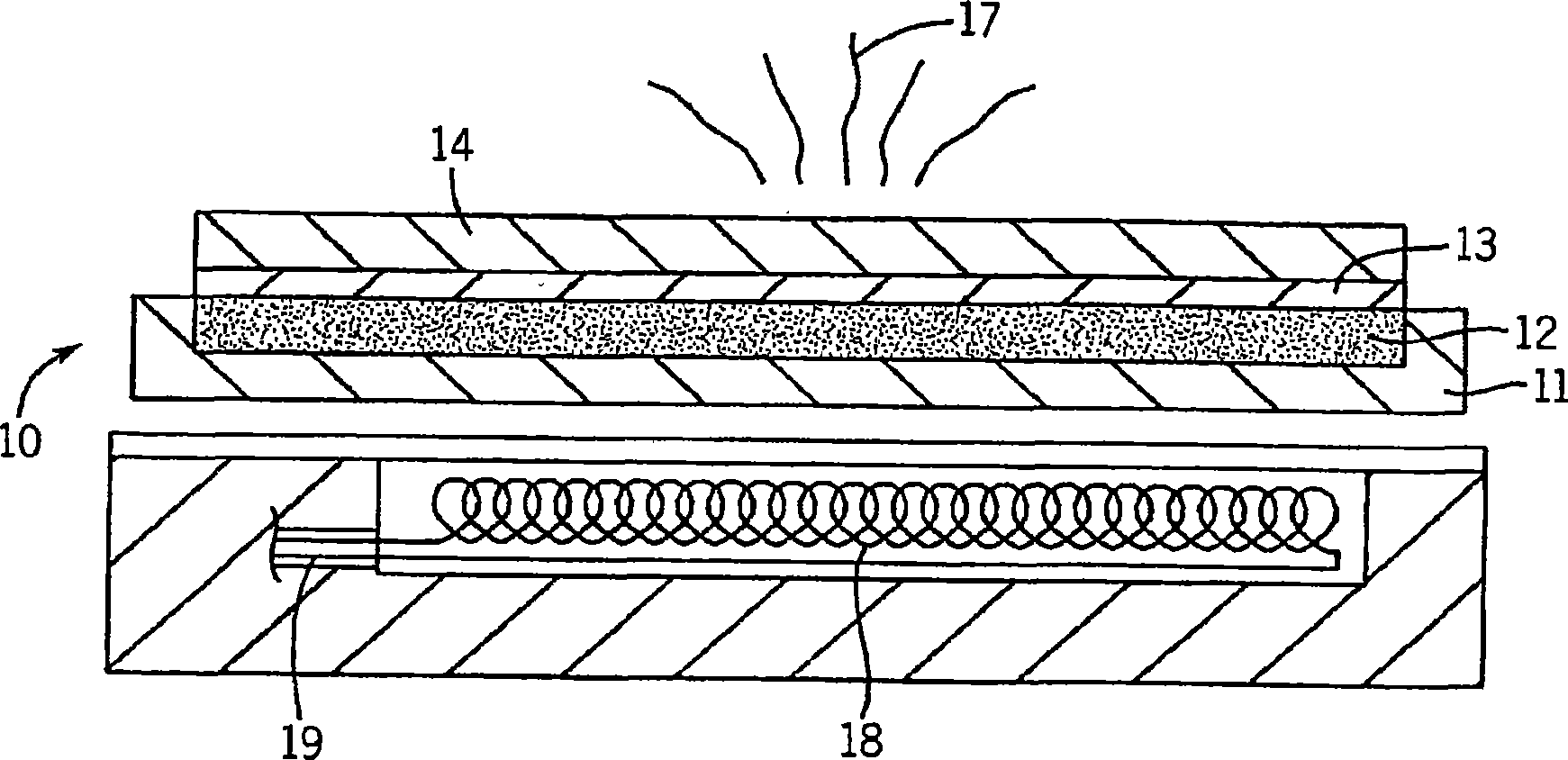

Heated volatile dispensing device with dye-based use-up indicator

InactiveCN101415575AReduce dissatisfactionAvoid wastingAir-treating devicesInvestigating time/temperature historyPorous substrateChange color

Owner:SC JOHNSON & SON INC

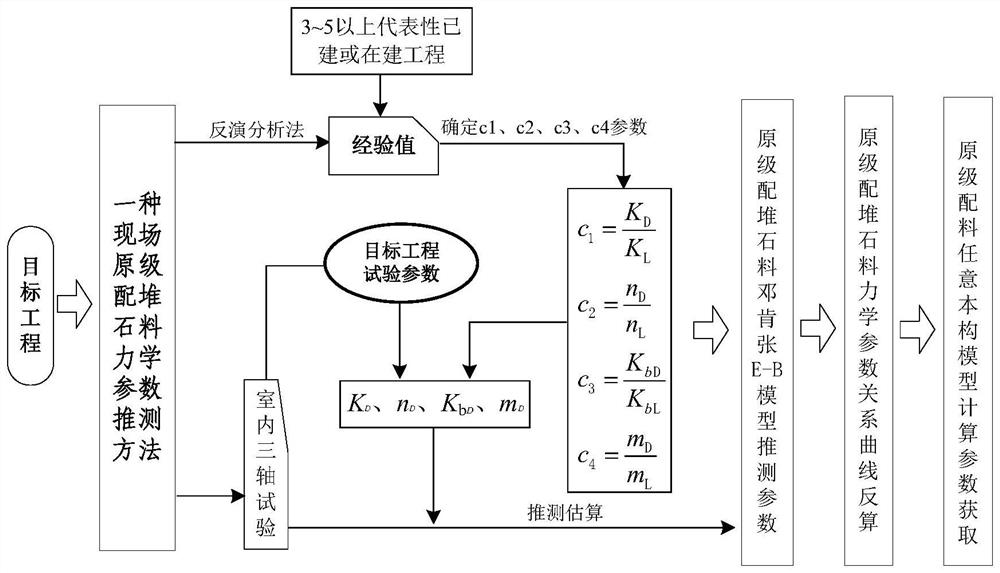

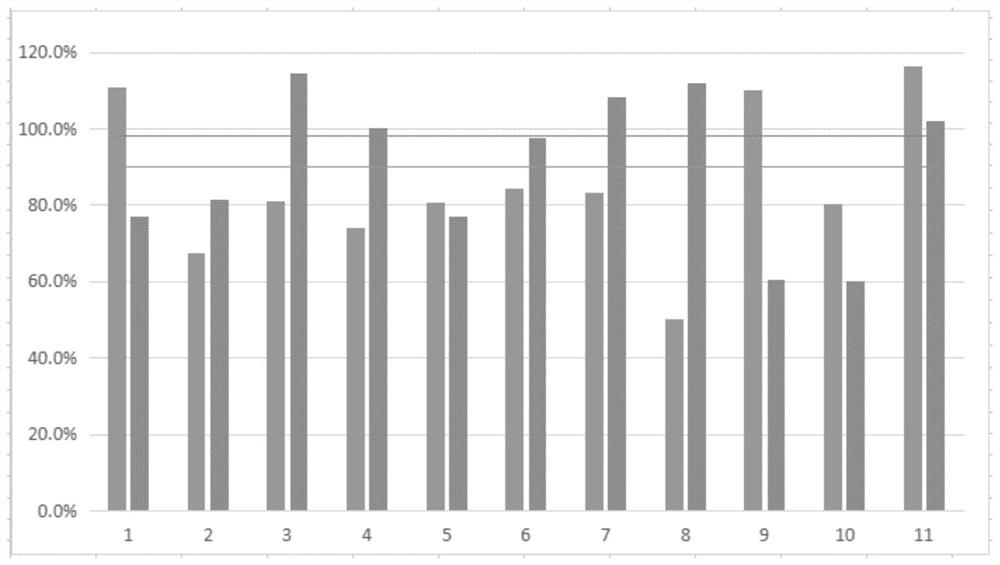

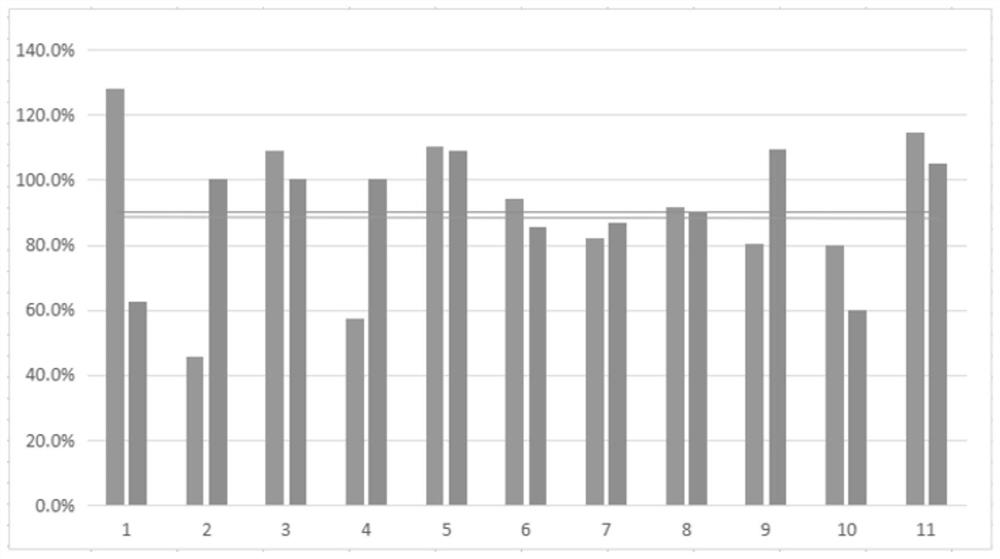

On-site original grading rockfill material mechanical parameter speculation method

PendingCN113204870ASimple methodTheoretical technology is feasibleDesign optimisation/simulationSpecial data processing applicationsObservation dataEngineering

The invention provides an on-site original grading rockfill material mechanical parameter speculation method which comprises the following steps: obtaining scale factors: obtaining scale effect scale factors which influence mechanical parameters through an engineering experience analogy method based on inversion analysis of prototype observation data of a constructed or under-construction project; estimating influence: approximately estimating the influence of a scale effect on calculation parameters on the basis of a Duncan-Zhang E-B model; performing equal-proportion calculation: performing parameter adjustment back calculation according to the estimated scale effect scale factor and the test parameters to obtain the mechanical parameters of the original grading rockfill material. The invention provides an effective method for acquiring the mechanical parameters of the original grading rockfill material for small and medium-sized projects without special scale effect research, and also provides a new thought and a new method for scale effect research of large and even giant projects; the method is simple, feasible in theoretical technology, easy to understand and operate, convenient to popularize and apply in engineering and high in practicability.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

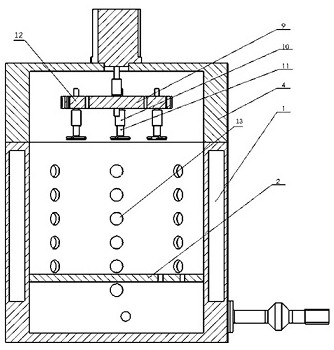

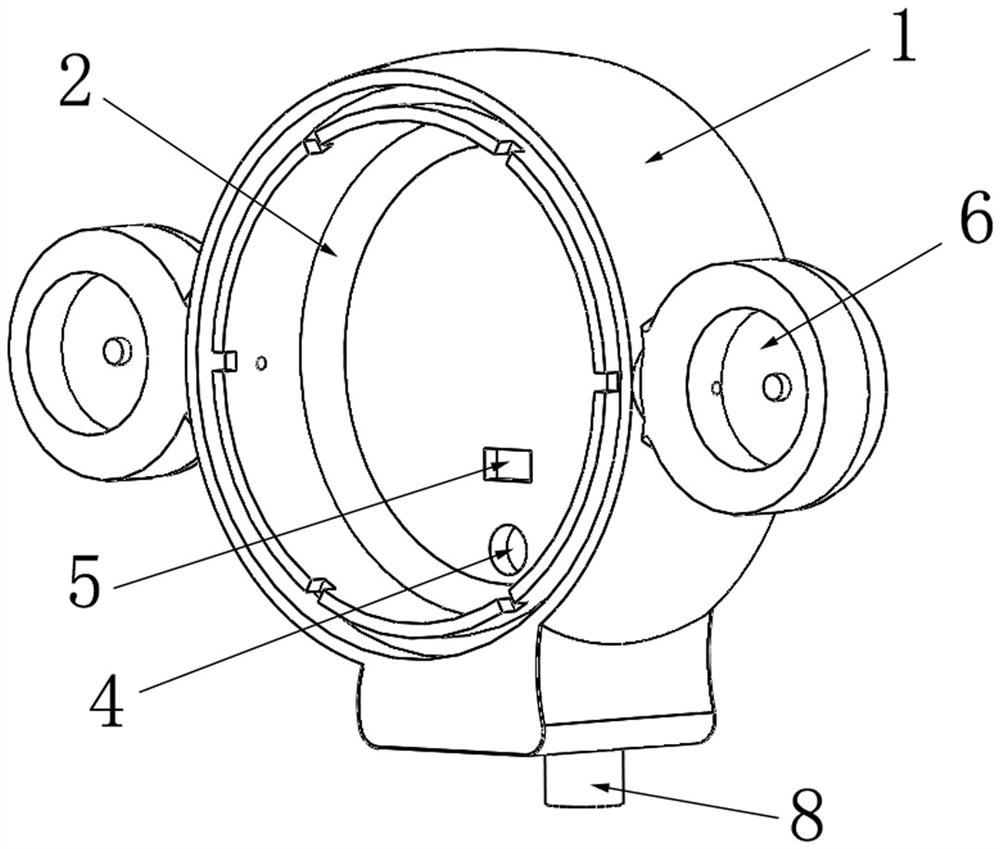

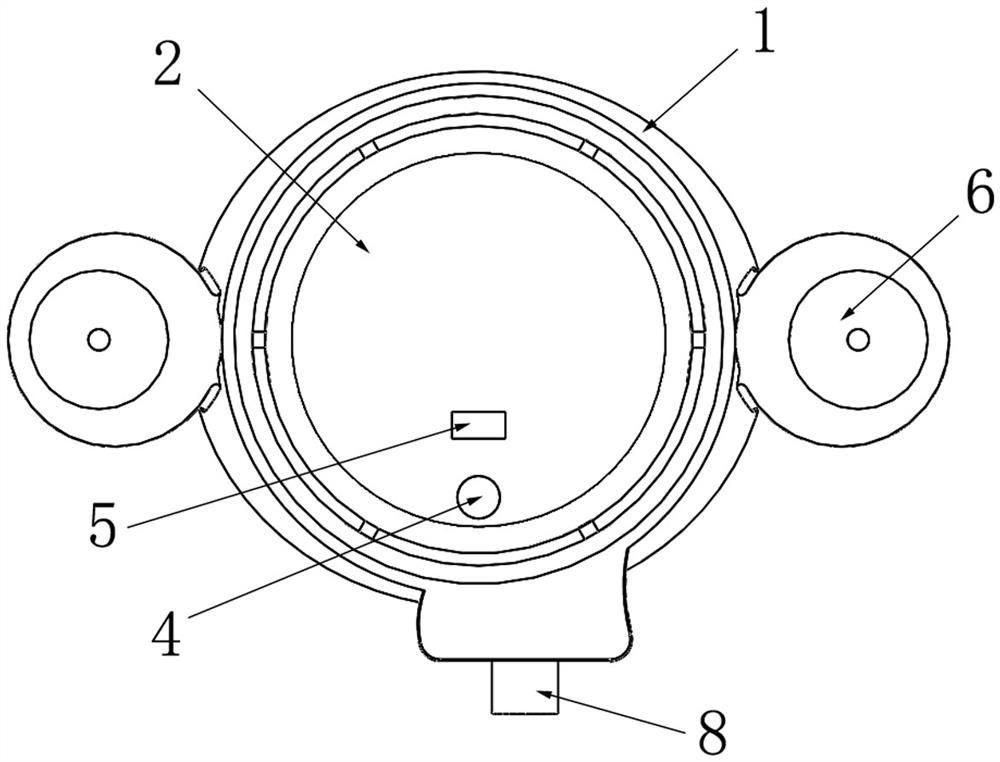

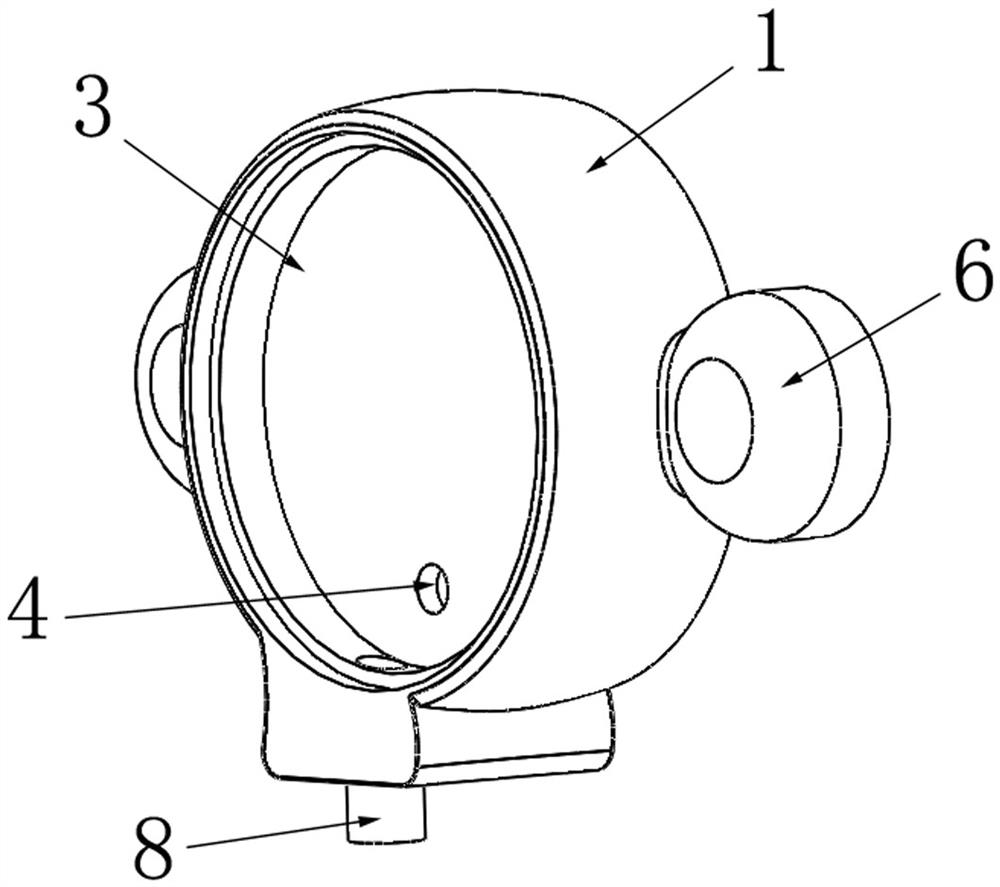

Brushless stator terminal assembling machine

PendingCN112134422ASave manpower and material resourcesIncrease productivityManufacturing stator/rotor bodiesMetal working apparatusMachineMaterial resources

The invention discloses a brushless stator terminal assembling machine which comprises a rack part, a protective cover part, a righting tool transverse moving part, a transverse moving conveying press-fitting part and a vibration disc feeding part. The righting tool transverse moving part, the transverse moving conveying press-fitting part and the vibration disc feeding part are arranged on the rack part, and the righting tool transverse moving part, the transverse moving conveying press-fitting part and the vibration disc feeding part are protected in the protective cover. The whole process is full-automatic, manpower and material resources are saved to the maximum extent, the production efficiency is improved, and meanwhile production accidents are avoided due to the full-automatic operation environment.

Owner:浙江巨力电机成套设备有限公司

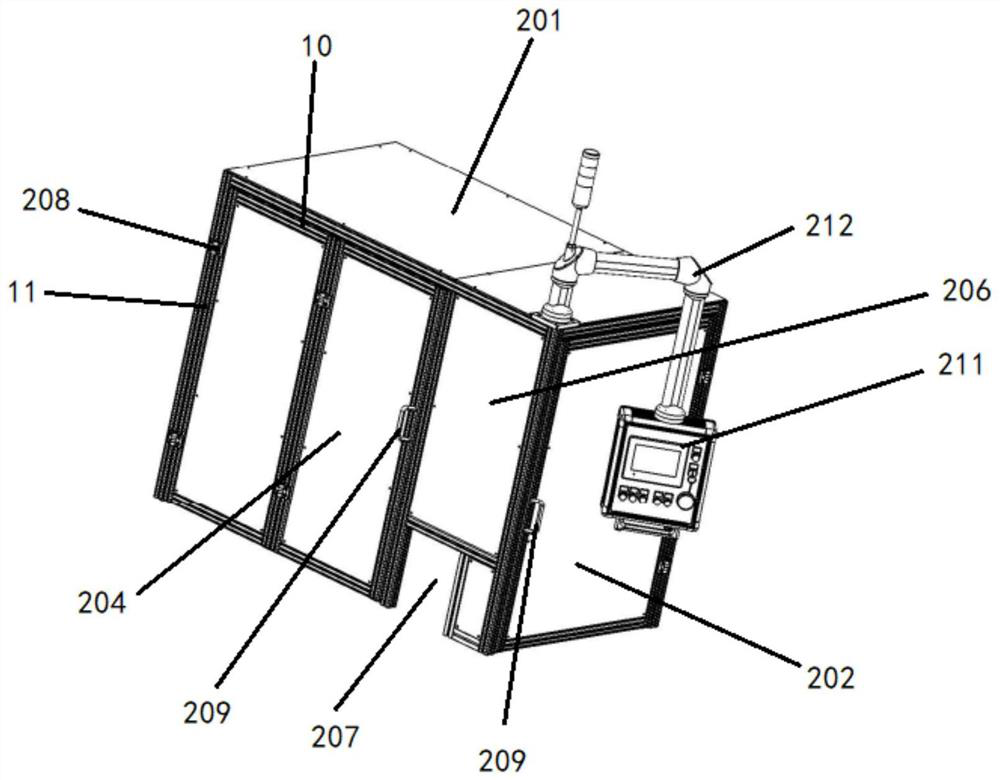

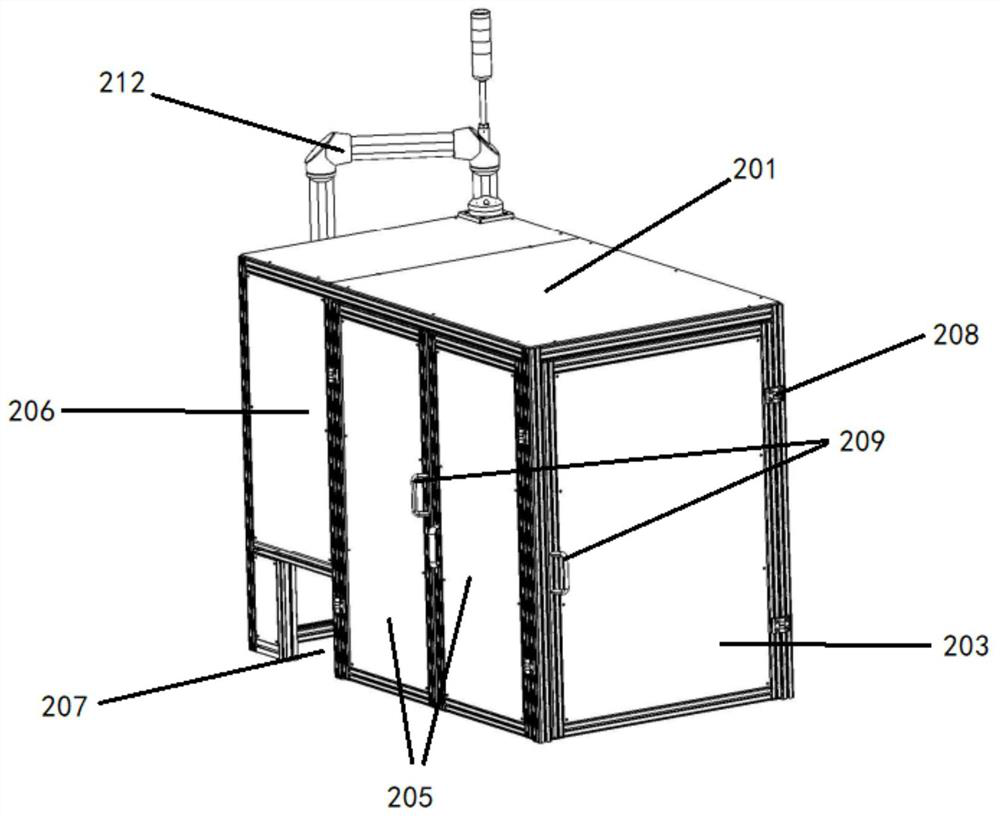

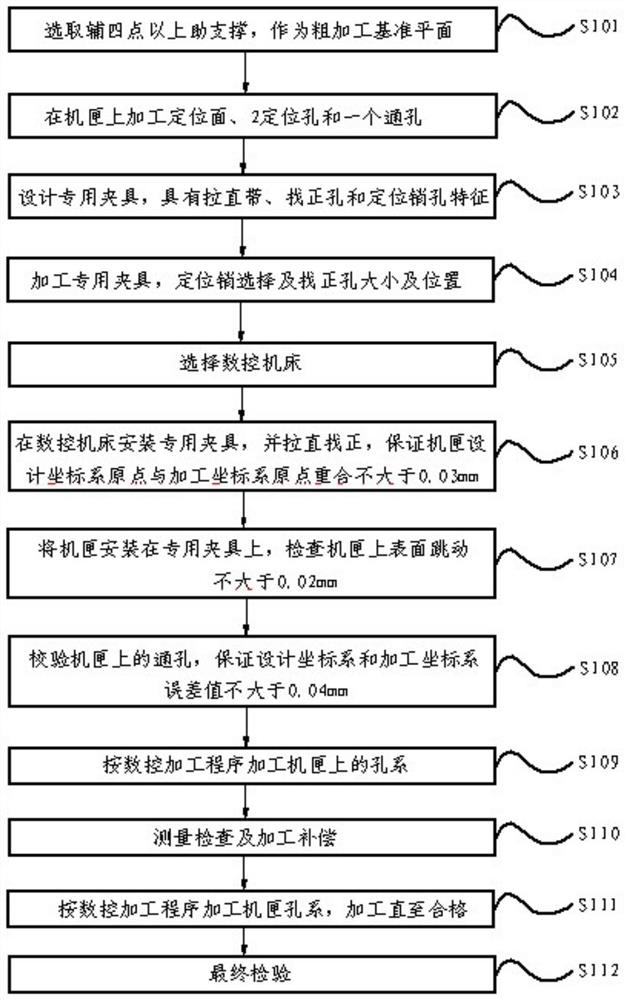

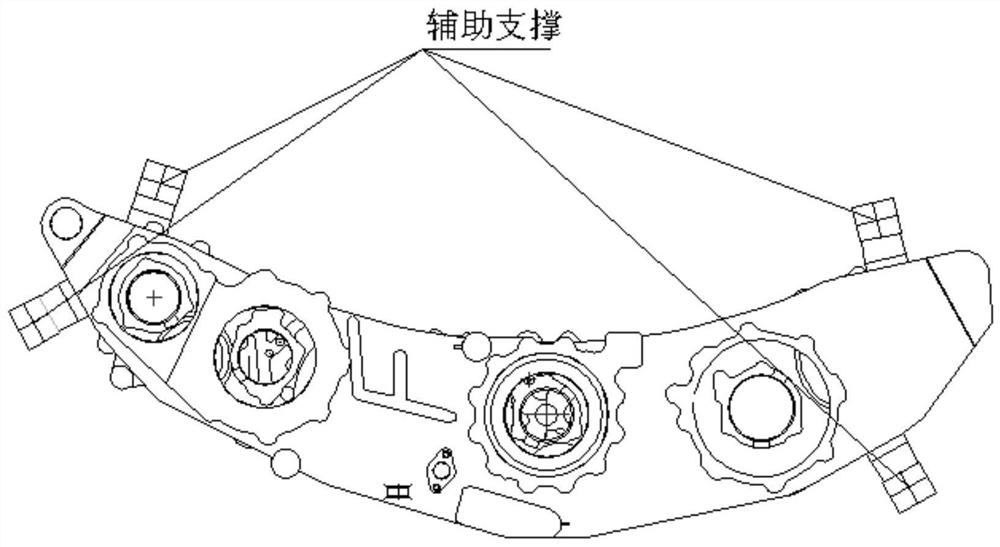

Machining method for guaranteeing position accuracy of cartridge receiver hole system

PendingCN112207309AAdd dowel holesAvoid error factorsPositioning apparatusMetal-working holdersNumerical controlAviation

The invention relates to a machining technology in the machining and manufacturing industry, in particular to a machining method for guaranteeing the position degree of a cartridge receiver hole system. The method can be applied to machining of cartridge receivers of aviation aircrafts or engine in three-axis, four-axis and five-axis numerical control machining centers, technicians or operators refer to the method and adopt the measures of adding auxiliary supports, adding positioning pin holes, manufacturing special clamps and the like according to the method specified in the machining flow schematic diagram, so that various error factors in the cartridge receiver machining process can be effectively reduced and avoided, all operation steps are easy to understand, qualified products can be machined, and meanwhile a feasible high-precision cartridge receiver hole machining mode is explored.

Owner:HARBIN DONGAN ENGINE GRP

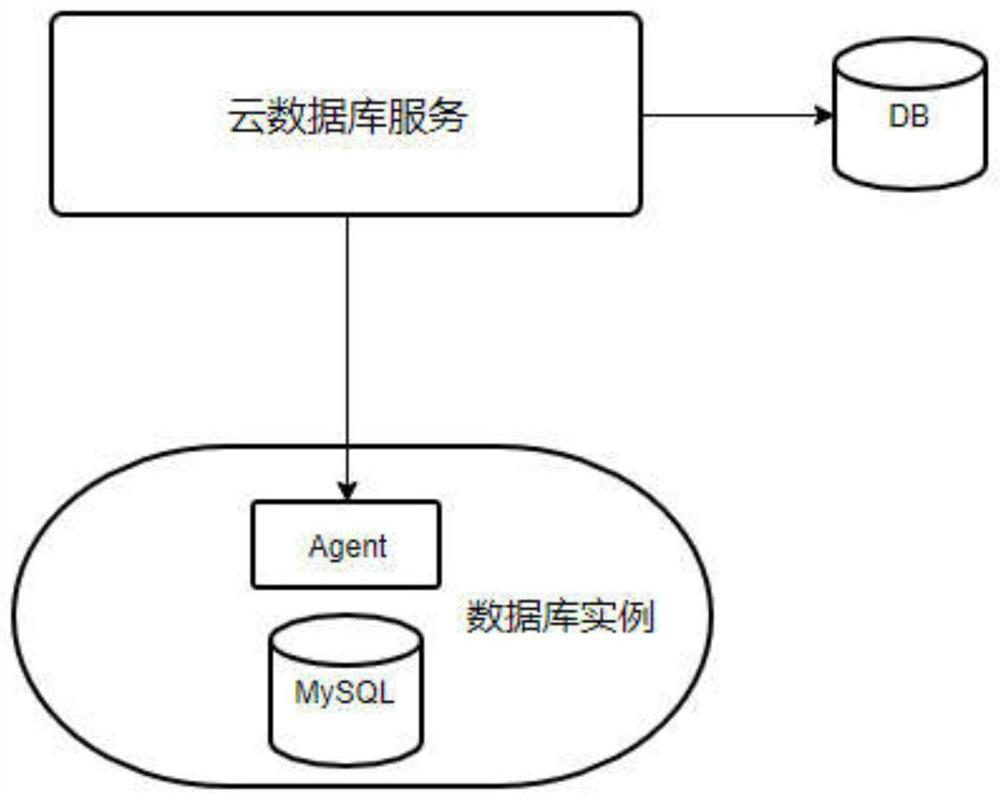

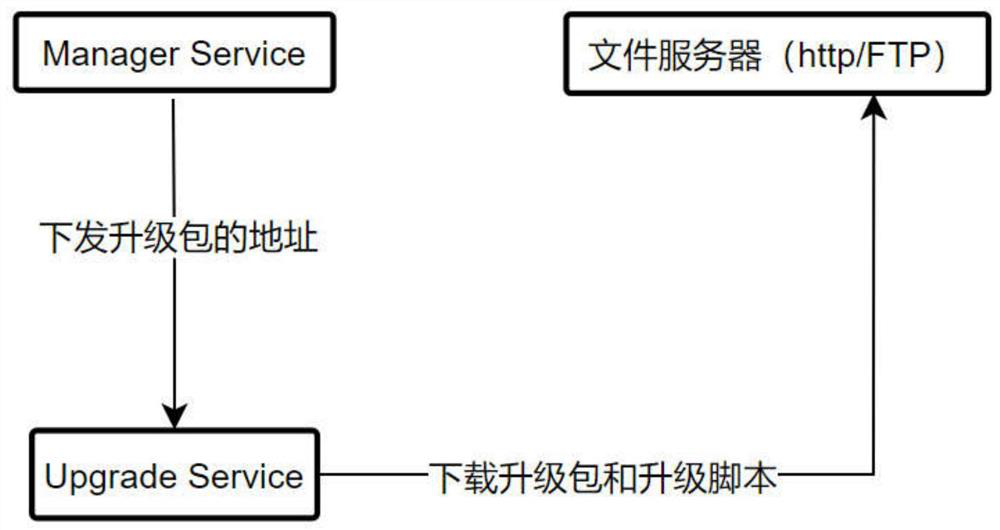

Method for upgrading Agent of cloud database

PendingCN111736877AQuick upgradeFill in the frame gapsTransmissionSpecial data processing applicationsDirectoryEngineering

The invention provides a method for upgrading an Agent of a cloud database. The method comprises the following steps: S1, storing Agent packages and software packages of different versions through a file server module; S2, selecting an instance to be upgraded through the front end, issuing an Agent upgrading request to a cloud database Manager service module, wherein the transmission request comprises transmission parameters; S3, providing an http service interface through a Upgrade Service module, and establishing connection between the cloud database Manager service module and the file server module by calling the interface of the cloud database Manager service module; and S4, downloading the upgrade package from the directory of the file server module by the Upgrade Service module through transmitting the package name given by the parameter. According to the method for upgrading the cloud database Agent, rapid upgrading of the cloud database Agent package is achieved, the frameworkblank is filled up, meanwhile, the interface is simple and clear, understanding and operation are easy, the functions are flexible and multipurpose, and the method can be used for upgrading the instance Agent and can also be used for upgrading an instance system.

Owner:紫光云技术有限公司

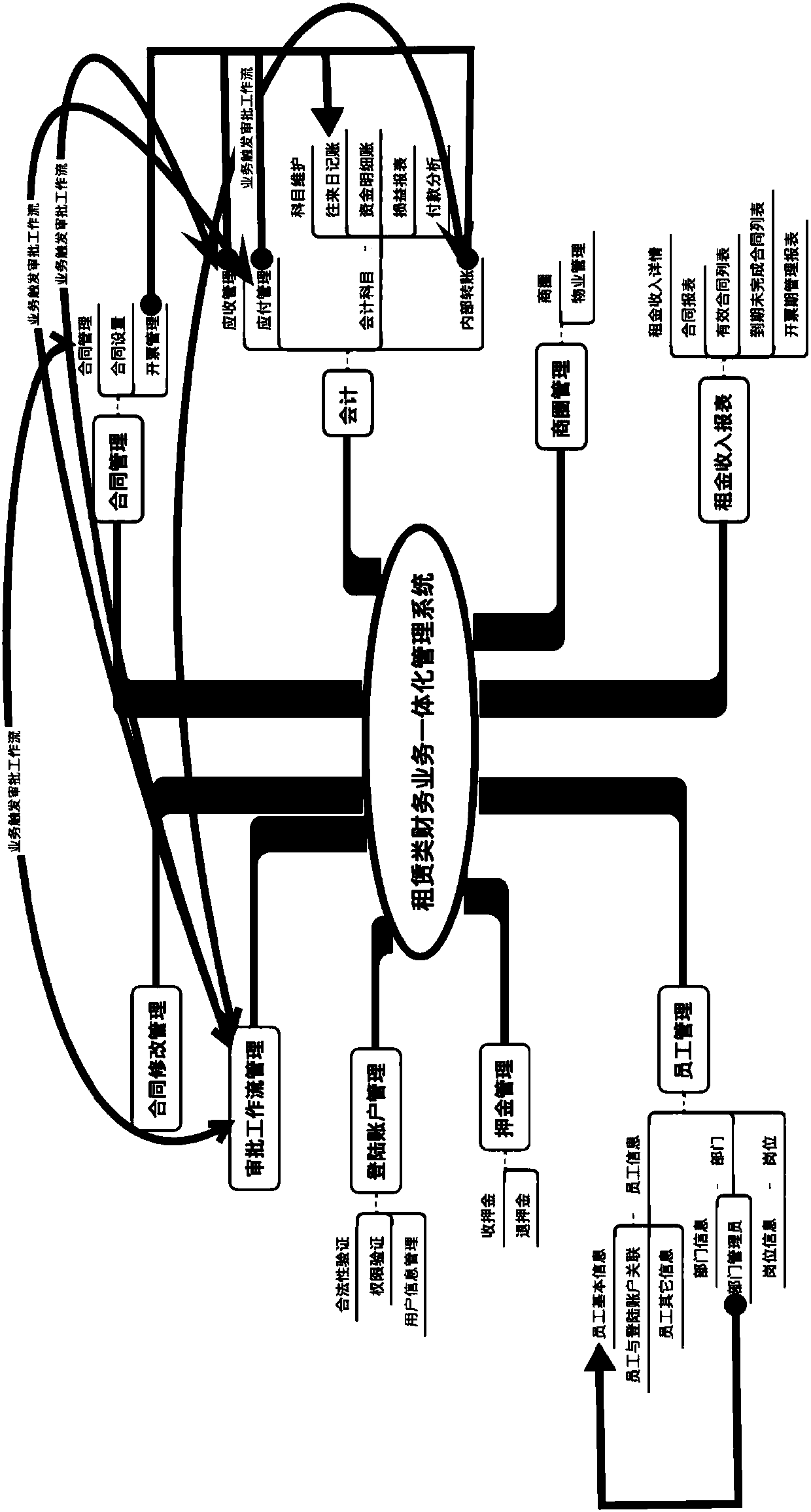

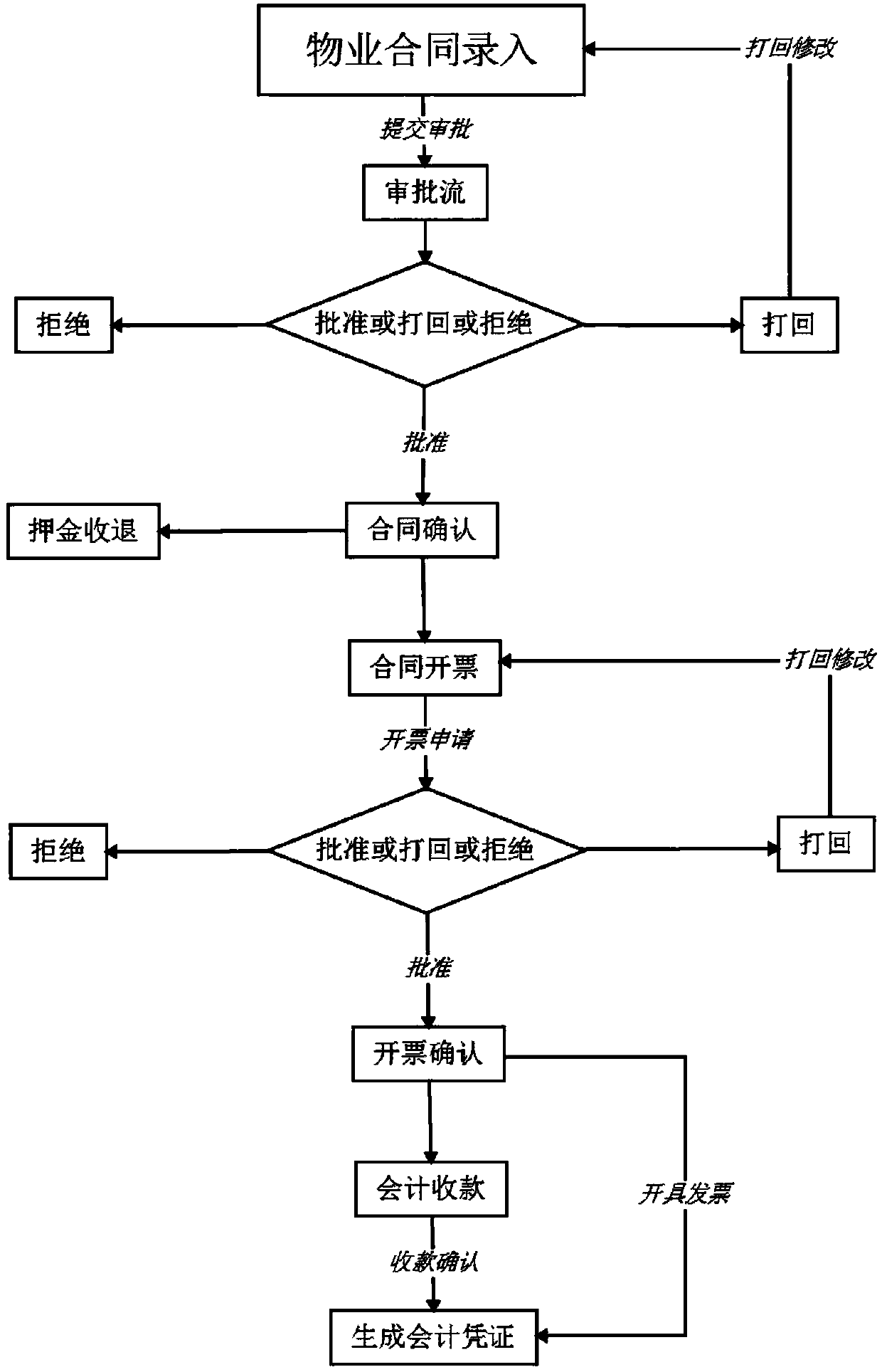

Leasing financial business management integrated management service system

PendingCN110490535ACode of PracticeEasy to operate and understandFinanceOffice automationGraphicsDisplay board

The invention relates to the technical field of real estate lease service. The invention discloses a leasing financial business management integrated management service system, comprising a login account management unit, an approval workflow management unit, a contract management unit, an accounting unit, a business district management unit and a rent income report unit, wherein the business district management unit is used for business district and property management, and the contract management unit comprises contract management, contract setting and billing management; and the accounting unit comprises receivable management, payable management, accounting projects and internal transfer. According to the leasing financial business management integrated management service system, variousfactors are considered in contract term management, and personalized schemes can be made for different clients, and the business process is comprehensively covered, and contract execution conditionsare reflected in various forms such as a display board, a calendar, a perspective table and a graph, and operation is convenient and easy to understand.

Owner:上海好才晤企业管理(集团)有限公司

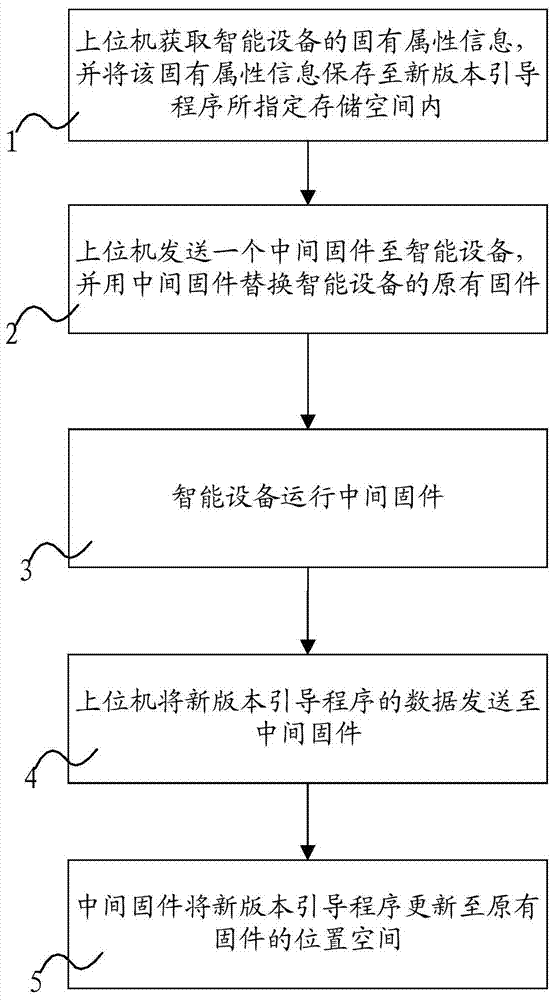

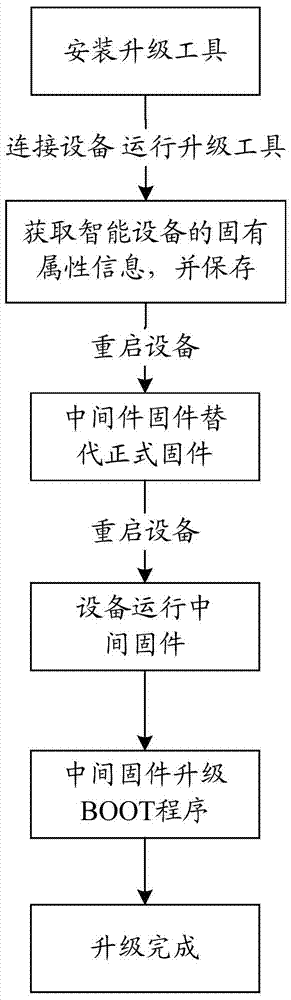

Method for realizing bootstrap automatic upgrade in intelligent equipment

ActiveCN104699500BImprove experienceEasy to operate and understandTransmissionSoftware deploymentTransport timeSmart device

The invention relates to a method for automatically upgrading a boot program in an intelligent device, which includes: a host computer obtains the inherent attribute information of the smart device, and saves the inherent attribute information in the storage space specified by the new version of the boot program; the host computer sends An intermediate firmware to the smart device, and replace the original firmware of the smart device with the intermediate firmware; the smart device runs the intermediate firmware; the upper computer sends the data of the new version of the boot program to the intermediate firmware; the intermediate firmware updates the new version of the boot program to The location space of legacy firmware. Adopting the method for realizing the automatic upgrade of the boot program in the smart device of the present invention, using the intermediate firmware to realize the automatic upgrade of the boot program, avoiding the original technical problems of having to return to the factory for disassembly and long transportation time, and at the same time not limited by time and place, the operation It is simple, free of cost, free from environmental constraints, improves user experience, and has a wider range of applications.

Owner:SHANGHAI HUACE NAVIGATION TECH

Milling head drive and up and down fine-tuning mechanism of steel plate double-sided bevel edge milling machine

ActiveCN102922028BAdjustable thicknessReduce noiseMilling equipment detailsDriving apparatusMilling cutterGear wheel

The invention relates to a milling head drive and up-and-down fine-tuning mechanism of a steel plate double-sided groove edge milling machine, which is characterized in that it includes a reducer, a flat key, a driving gear, a gear end cover, a transition gear, a driven gear, a milling cutter shaft, Milling head and large round nut. The structure of the invention is simple, compact and reasonable; when adjusting the displacement of the milling cutter head, the operator only needs to rotate the adjusting nut on the top of the milling cutter shaft to adjust the thickness of the groove, and the angle of the milling cutter head can be selected according to the different requirements of the groove And the direction; the groove noise of the present invention is small, adopts a completely mechanical cutting and milling processing method, has no thermal deformation and uneven surface, the surface of the groove is smooth after processing, no need for secondary grinding, the mechanism is easy to understand, and is suitable for various jobs environment and reduce the labor intensity of workers.

Owner:WUXI HUALIAN SCI & TECH GROUP

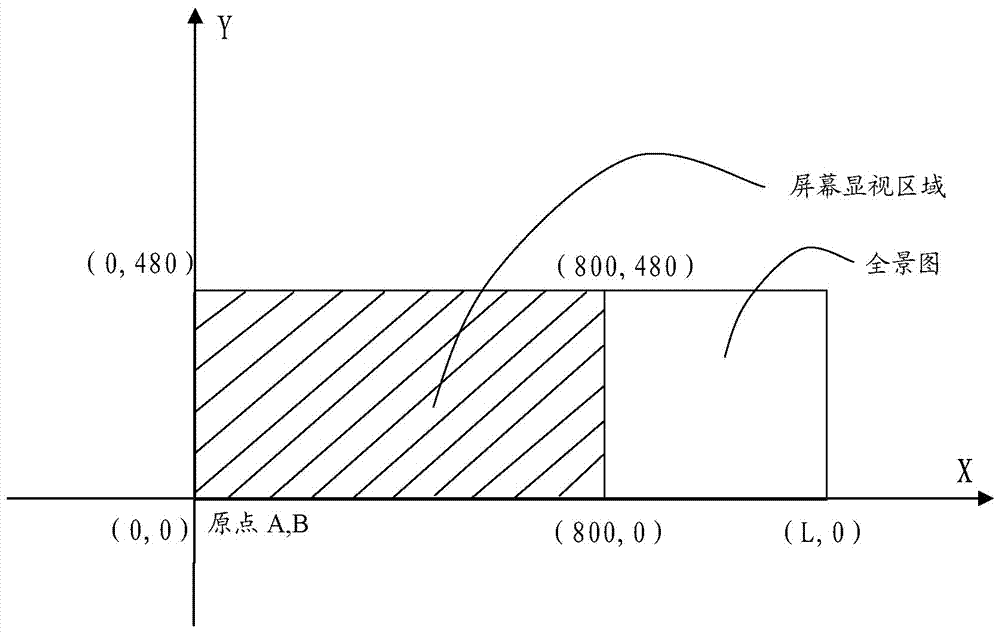

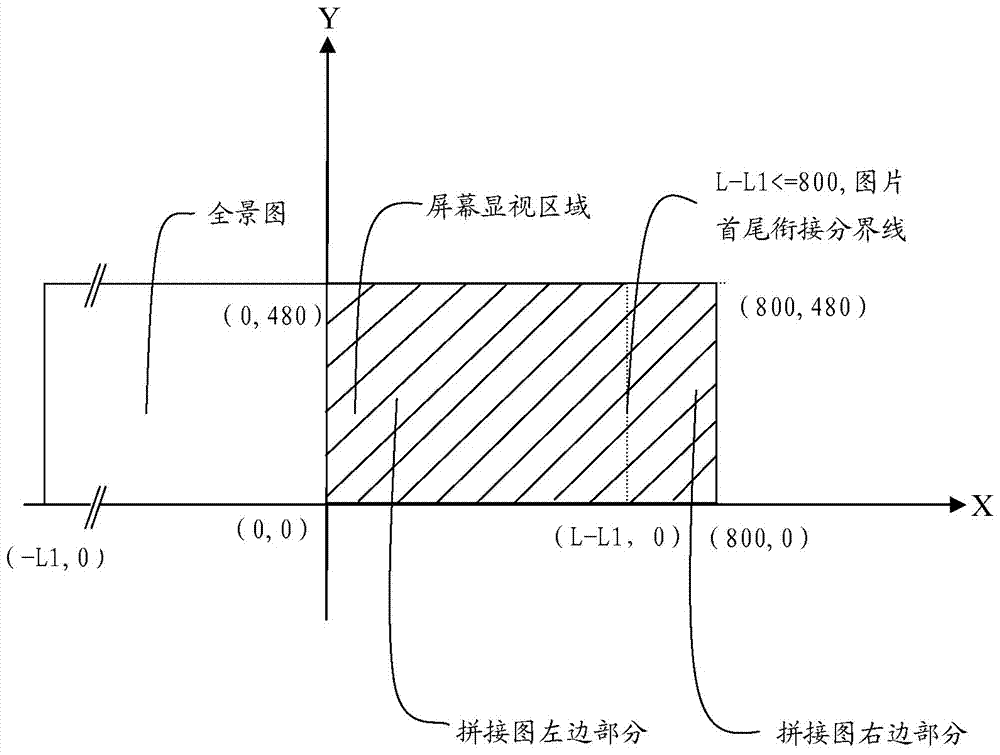

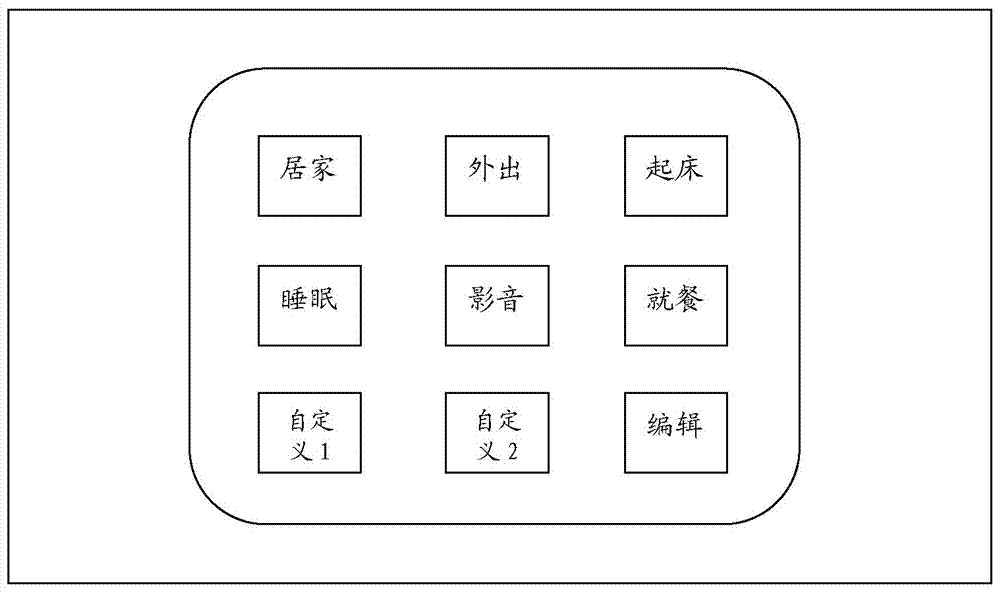

A smart home control device and method based on panoramic view

ActiveCN104181884BEasy to operate and understandSimple human-computer interactionComputer controlInput/output processes for data processingPosition controlComputer science

The present invention provides a smart home control device and method based on a panoramic view, which shoots and edits a panoramic view inside a living room; generates a coordinate set of image area positions of controlled equipment in the panoramic view; Control link of the image area of the controlled device; load the panorama to the touch screen to realize seamless splicing and circular display; click the image of the controlled device in the panorama to realize the visual control of the actual controlled device; set the floating shortcut operation button And the pull-down slide-out operation window can quickly and easily establish a vivid and intuitive dynamic real-scene operation interface, which is extremely easy for users to use and greatly saves the cost of engineering construction.

Owner:XIAMEN LEELEN TECH CO LTD

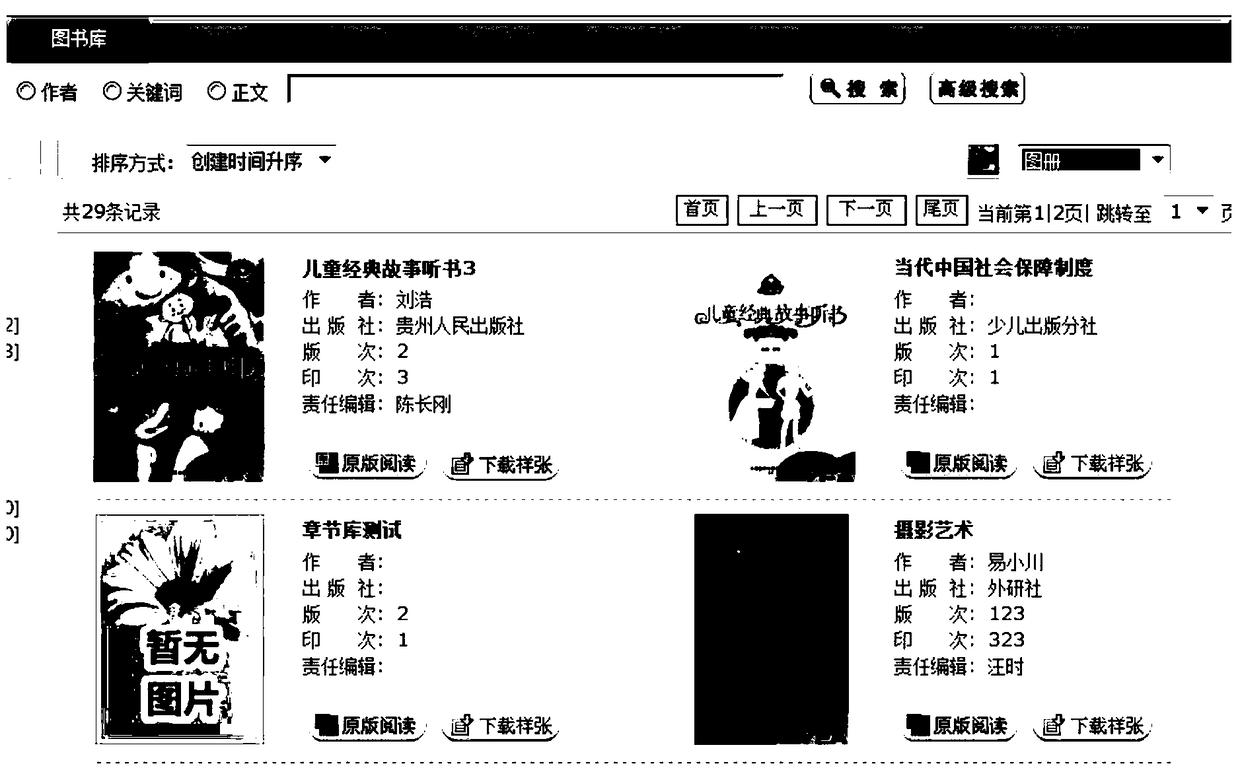

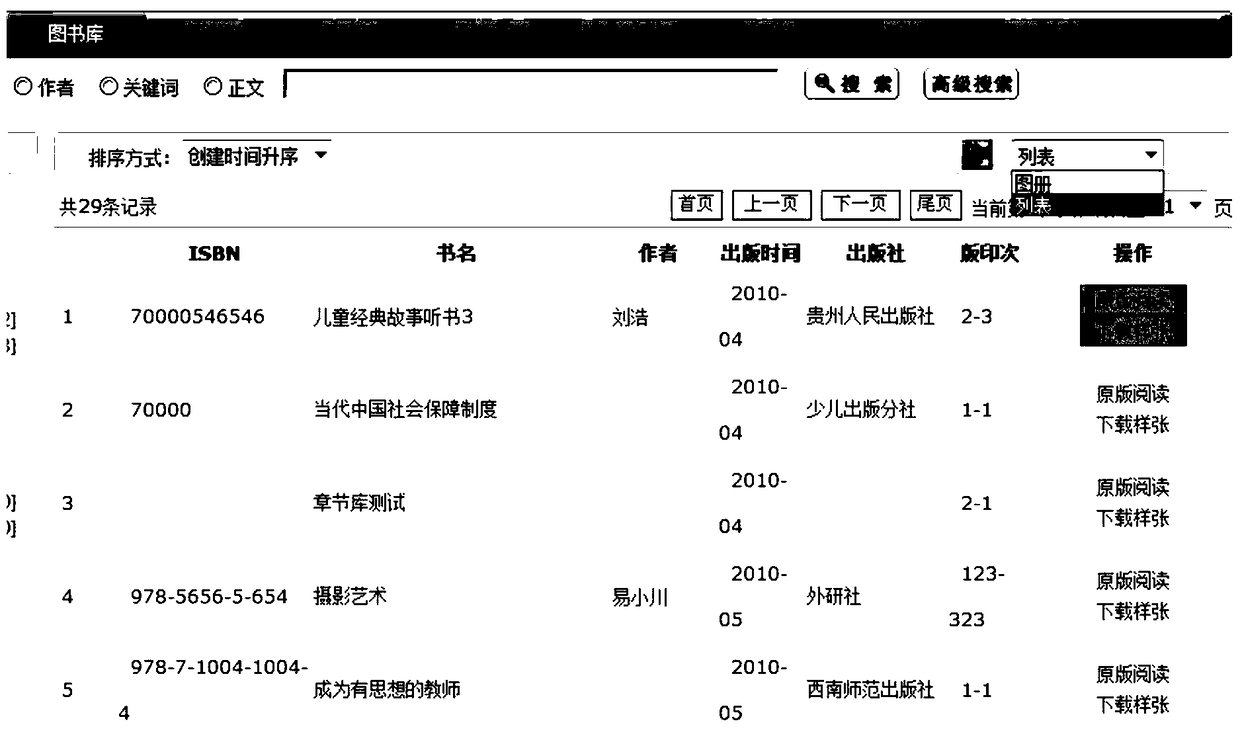

Web page publishing method and system

InactiveCN104424266BFlexible configurationReduce duplication of development workSoftware engineeringWebsite content managementWeb pageDatabase

The invention discloses a web page publishing method and a web page publishing system, and the method comprises the following steps: sequentially loading various functional zones of a page; to the functional zones demanded to be loaded, reading components and templates configured in the functional zones from a database; processing the corresponding components to obtain data in the functional zones; loading the data into the templates to complete loading of the functional zones; obtaining a complete page after loading all functional zones; publishing the page. According to the method and the system, the page can be flexibly configured so that the repeated development is reduced and the development efficiency is improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

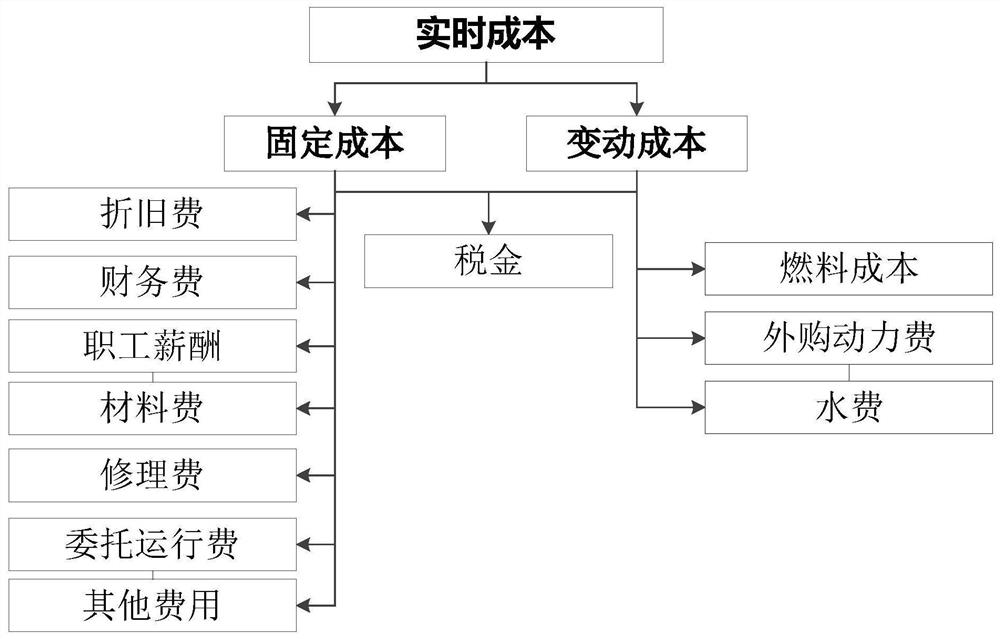

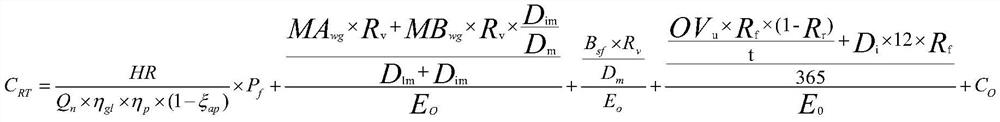

Coal-fired power plant real-time cost measuring and calculating method based on production and financial data

PendingCN112435056AEasy accessSimplify data collection workloadMarket predictionsInformation technology support systemData ingestionProcess engineering

The invention discloses a coal-fired power plant real-time cost measuring and calculating method based on production and financial data. The problem that a measuring and calculating method in the existing real-time cost measuring and calculating process is not comprehensive and has data errors is solved by utilizing daily production and financial data of a power plant. The calculation method comprises the steps of obtaining daily production and financial data of the coal-fired power plant; dividing cost data categories, dividing the real-time cost into fixed cost and variable cost, and extracting the data into the divided data categories; establishing a power supply coal consumption model, substituting power plant production data into the power supply coal consumption model to calculate toobtain a power supply coal consumption value, and substituting fuel price data and the power supply coal consumption value into the model to calculate to obtain a fuel cost value; establishing a real-time cost calculation model, and substituting production and financial data into the cost calculation model to obtain other cost values; and summing the change cost value and the fixed cost value toobtain a real-time total cost value. The calculation model is simple, clear and easy to understand and operate.

Owner:GUIZHOU WUJIANG HYDROPOWER DEV +1

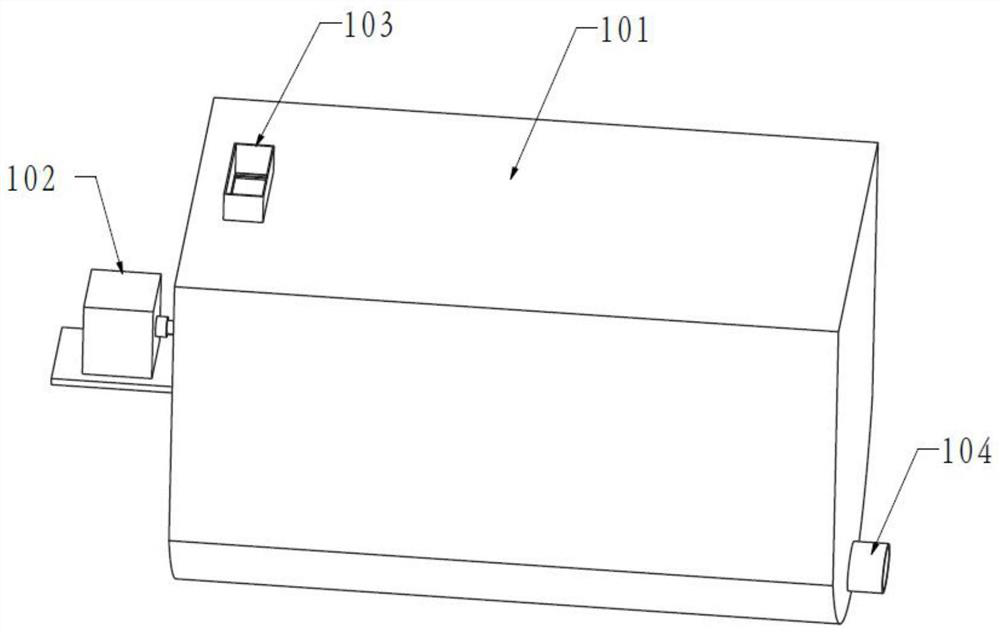

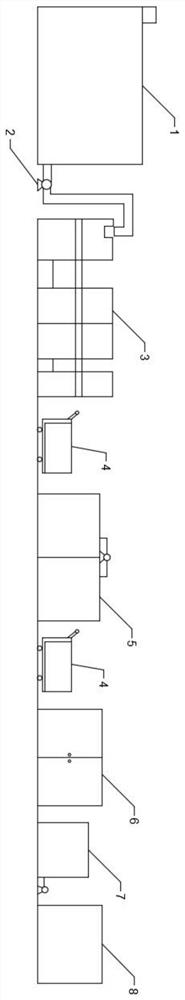

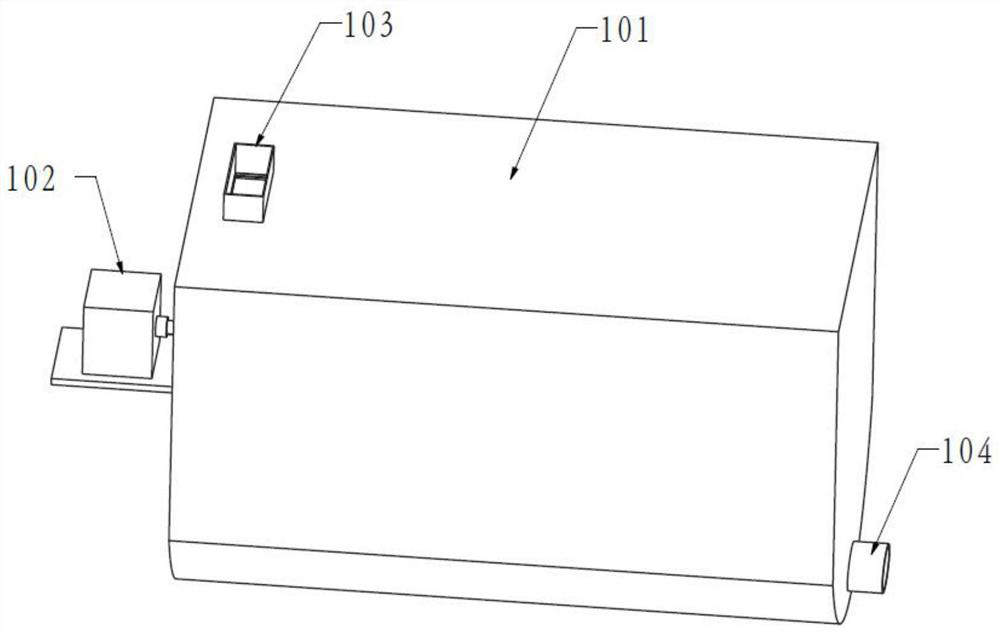

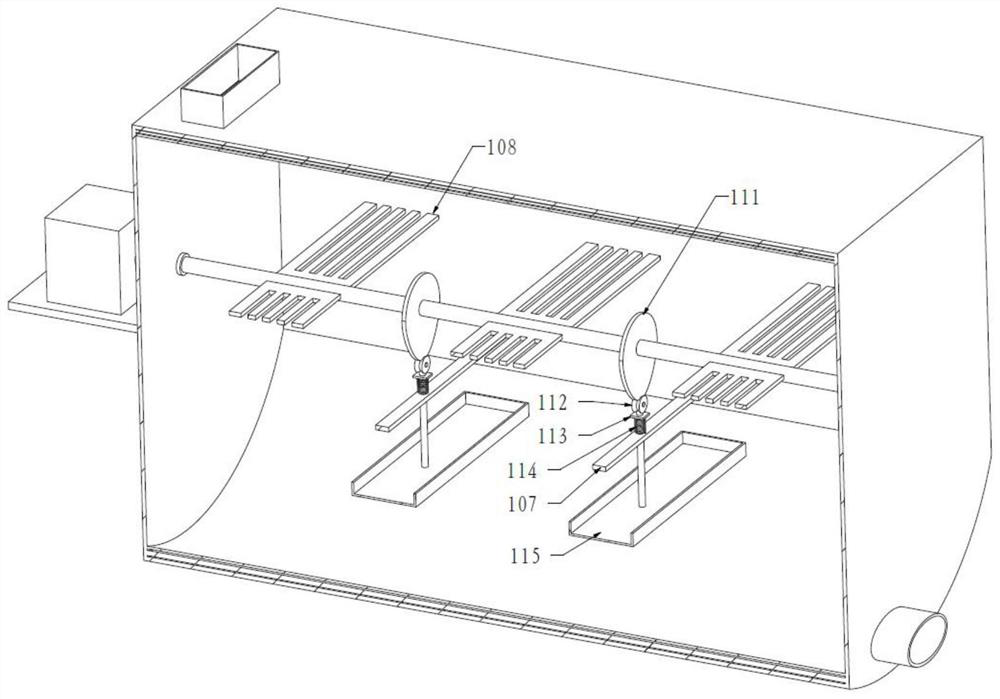

A kind of production equipment and production process of fungus bag

ActiveCN111837814BStir wellReduce energy consumptionCultivating equipmentsMushroom cultivationProcess engineeringTruck

The invention discloses a fungus package production equipment and production process, which belongs to the technical field of fungus production, and includes a culture material mixer, an automatic packaging machine, a fungus package cooling room, an inoculation machine and a culture room, and the culture material mixer includes a main stirring machine Mechanism and auxiliary stirring mechanism, the main stirring mechanism is arranged above the auxiliary stirring mechanism; the raw material mixer is connected with a rotary conveyor to transport the uniformly mixed raw materials to the automatic packaging machine for loading, bagging, inserting, nest and other operations, and pack the bacteria into the transport frame, and then transport them to the pulsating vacuum sterilizer by a fast moving vehicle; the pulsating vacuum sterilizer divides the sterilization chamber into partitions through the middle partition, and each partition The bacteria chamber can independently control the steam on-off and vacuum state; the sterilized materials are transported to the bacterial bag cooling room by a fast moving vehicle for cooling. room for cultivation.

Owner:湖南神骏农业科技发展有限公司

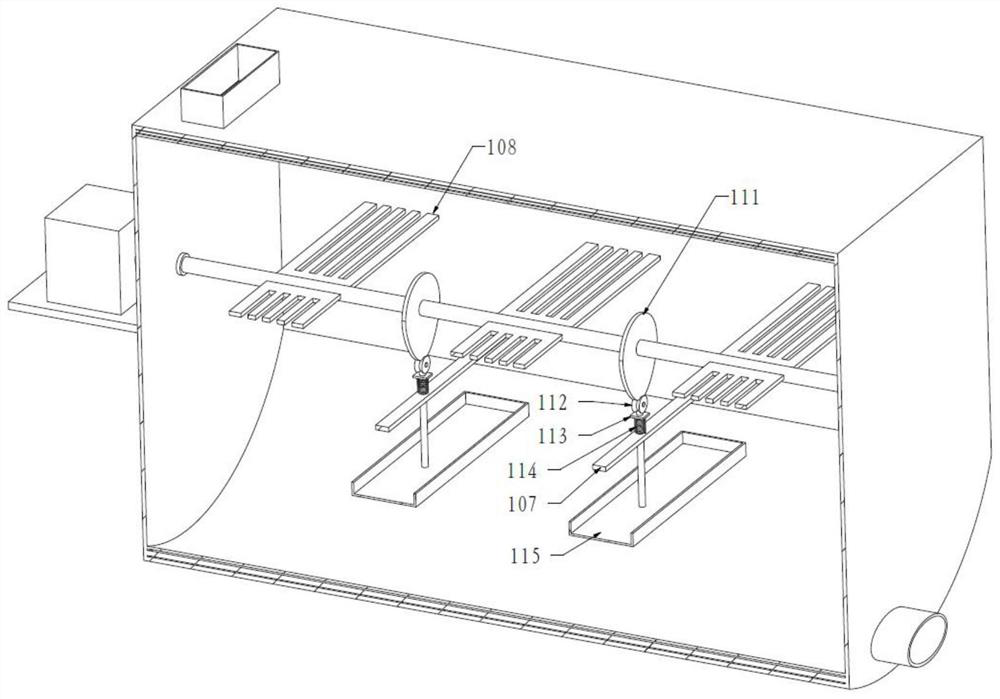

A vibrating walnut picker

ActiveCN108271529BHarvesting is safe, economical and efficientCompact structurePicking devicesWalnut NutAgricultural engineering

The invention relates to a vibration-type walnut picking machine, and belongs to the technical field of agricultural mechanical equipment. The picking machine comprises a vibration picking part, a hollow supporting connecting rod and a power supply; the vibration picking part and the power supply are respectively arranged at two ends of the supporting connecting rod; a wire is arranged in the middle cavity of the supporting connecting rod; and the vibration source of the vibration picking component is connected with the power supply through the wire. The picking machine can be suitable for different environment conditions, and is safe, economic and efficient. The vibration-type walnut picking machine disclosed by the invention has the characteristics of simple and compact structure, safe and reliable performance, convenient and easily understood operation, easy carrying, high efficiency and the like, and the picking machine avoids the danger that people climb a tree for picking and fall down.

Owner:KUNMING UNIV OF SCI & TECH

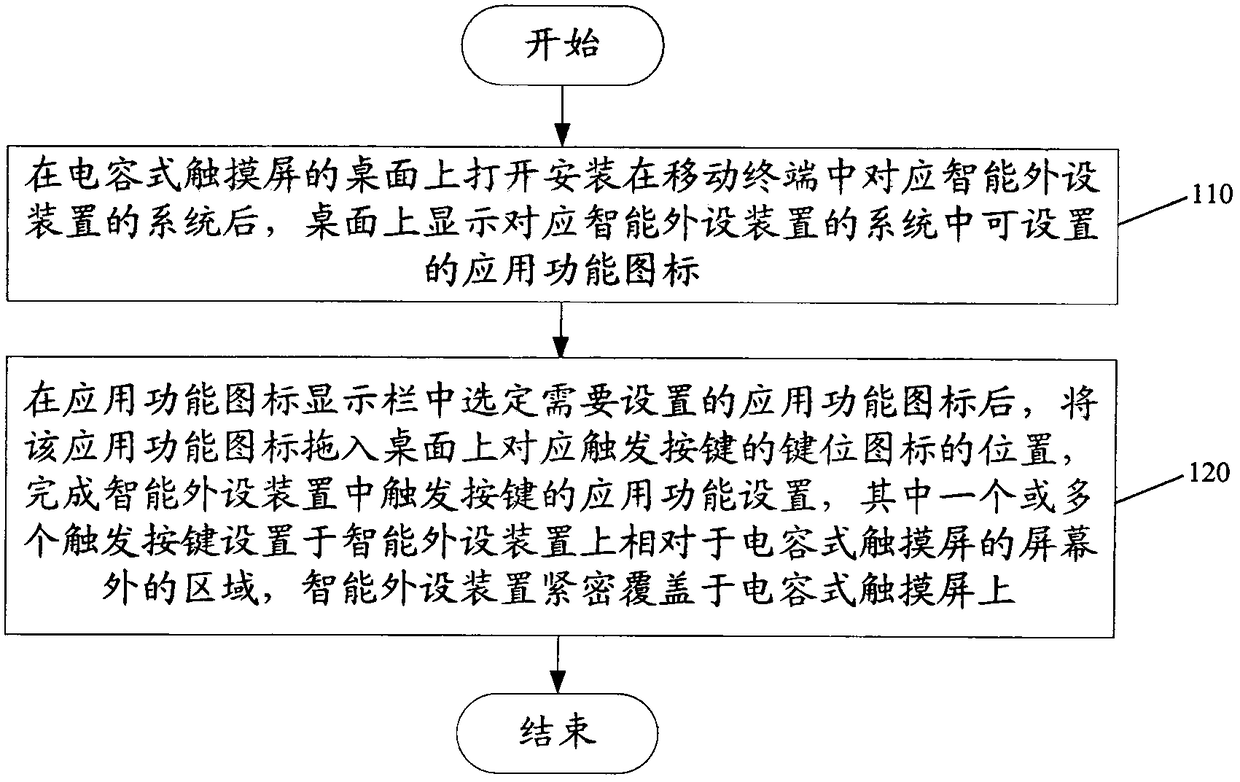

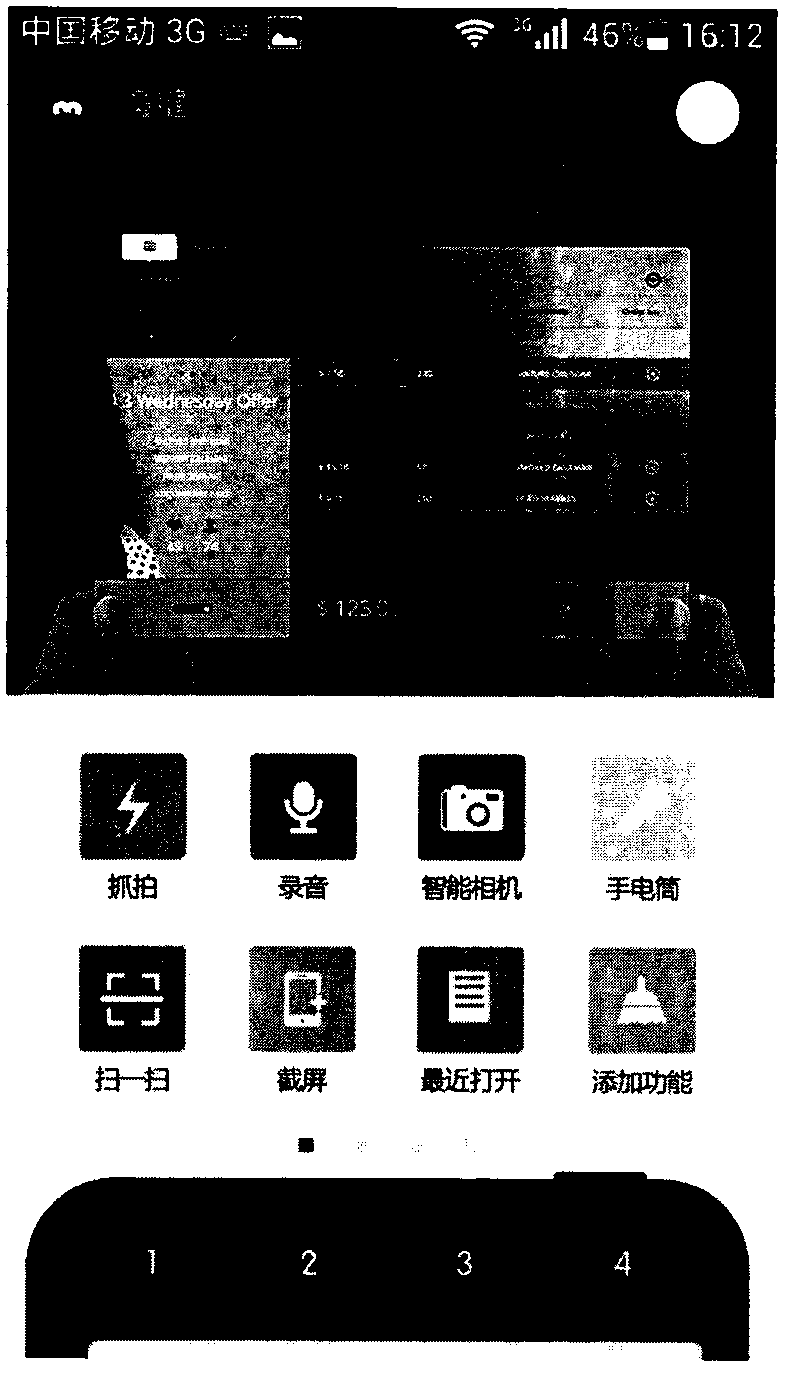

Control method for setting operation interface based on capacitive touch screen intelligent peripheral device

ActiveCN105892873BImprove user experienceSimple and unified operationInput/output processes for data processingComputer hardwareEngineering

The invention discloses a capacitive touch screen based operation interface setting control method for an intelligent peripheral apparatus. The method comprises the steps of starting a system corresponding to the intelligent peripheral apparatus and installed in a mobile terminal on a desktop of a touch screen, and displaying application function icons settable in the system corresponding to the intelligent peripheral apparatus on the desktop; and selecting an application function icon required to be set in an application function icon display bar, dragging the application function icon into a position corresponding to a key icon of a trigger key on the desktop, and finishing application function setting of the trigger key in the intelligent peripheral apparatus, wherein one or more trigger keys are arranged in a region outside a screen, opposite to the touch screen, of the intelligent peripheral apparatus closely covering the touch screen. According to the method, the problem of inconvenient operation interface setting of the system corresponding to the intelligent peripheral apparatus and installed in the mobile terminal caused by the phenomenon that a user finishes function setting by multi-time clicking in an operation interface interaction mode of APPs in the mobile terminal at present is solved.

Owner:深圳市瑞捷恩科技有限公司

Can bus test system and can bus test method based on uds

ActiveCN110233768BEasy to set upEasy to operate and understandElectric testing/monitoringBus networksUSBEmbedded system

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

Numerical control milling machine angle-adjustable four-axis rotary workbench

PendingCN109176047AImprove effective utilizationReduce processing costsLarge fixed membersNumerical controlEngineering

The invention relates to a numerical control milling machine angle-adjustable four-axis rotary workbench which comprises an outer shell, an input shaft, a first bevel gear, a second bevel gear, a four-axis workbench body, a swing shaft, an angle adjusting middle shaft, an angle fixing pull nail, a pull nail limiting support, a dial, an inner ring sleeve, a middle sleeve and an outer side sleeve, wherein the first bevel gear and the second bevel gear are mutually engaged, and the inner ring sleeve, the middle sleeve and the outer side sleeve are sequentially sleeved. The input shaft extends outof the outer shell, the other end of the input shaft is provided with the first bevel gear, the outer side sleeve and the middle sleeve clamp a guide rail arranged on the outer shell, the inner ringsleeve extends out of the outer shell and is fixedly connected with the four-axis workbench body, the other end of the inner ring sleeve is provided with the second bevel gear, the swing shaft is sleeved with the inner ring sleeve, the other end of the swing shaft is fixedly connected with the angle adjusting middle shaft, the angle adjusting middle shaft extends out of the outer shell and is connected with the dial, and the angle fixing pull nail is clamped to the dial to be positioned. The angle adjusting structure is added, the function of five-axis positioning machining can be achieved, the part machining range is greatly enlarged, and the effective using rate of a machine tool is improved.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

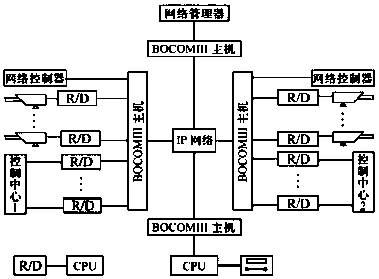

Digital network monitoring system

InactiveCN108076324ASimple structureEasy to operate and understandTelevision system detailsColor television detailsMonitoring systemStructure of Management Information

The invention discloses a digital network monitoring system; a network manager is connected with a BOCOMIII host, the BOCOMIII host is connected with an IP host, the IP host is connected with the BOCOMIII host, the BOCOMIII host is connected with a CPU, the CPU is connected with a computer, the BOCOMIII host is connected with a monitor through R / D, the BOCOMIII host is connected with a network device, and the BOCOMIII host is connected with a control center through the R / D. The system is simple in structure and convenient to understand and operate; information amount of view information is large, and two effective means of a dynamic control process and an information recording process are provided, so that real-time monitoring can be achieved, and viewing can be facilitated.

Owner:TAICANG DINGCHENG ELECTRONICS TECH CO LTD

Production equipment and production technology of auricularia auricula fungus bags

ActiveCN111837814AStir wellReduce energy consumptionCultivating equipmentsMushroom cultivationCooling chamberProcess engineering

The invention discloses production equipment and production technology of auricularia auricula fungus bags and belongs to the technical field of auricularia auricula production. The production equipment comprises a culture material mixer, an automatic packaging machine, a fungus bag cooling chamber, an inoculation machine and a culture chamber, wherein the culture material mixer comprises a main mixing mechanism and an auxiliary mixing mechanism; the main mixing mechanism is arranged at the upper part of the auxiliary mixing mechanism; the culture material mixer is connected with a rotary conveyor for conveying the evenly mixed materials into the automatic packaging machine to carry out operations, such as charging, bagging, rod insertion and nesting, and fungus bags are loaded into conveying boxes and then transported into a pulse vacuum sterilizer through a fast transportation vehicle; the pulse vacuum sterilizer partitions a sterilization chamber through a middle partition plate, and the sterilization chamber of each partition can independently control on / off of steam and a vacuum state; the sterilized materials are transported into the fungus bag cooling chamber to be cooled through the fast transportation vehicle; the fungus bag cooling chamber is connected with the inoculation machine; and the materials are transported into the culture chamber to be cultivated after beinginoculated.

Owner:湖南神骏农业科技发展有限公司

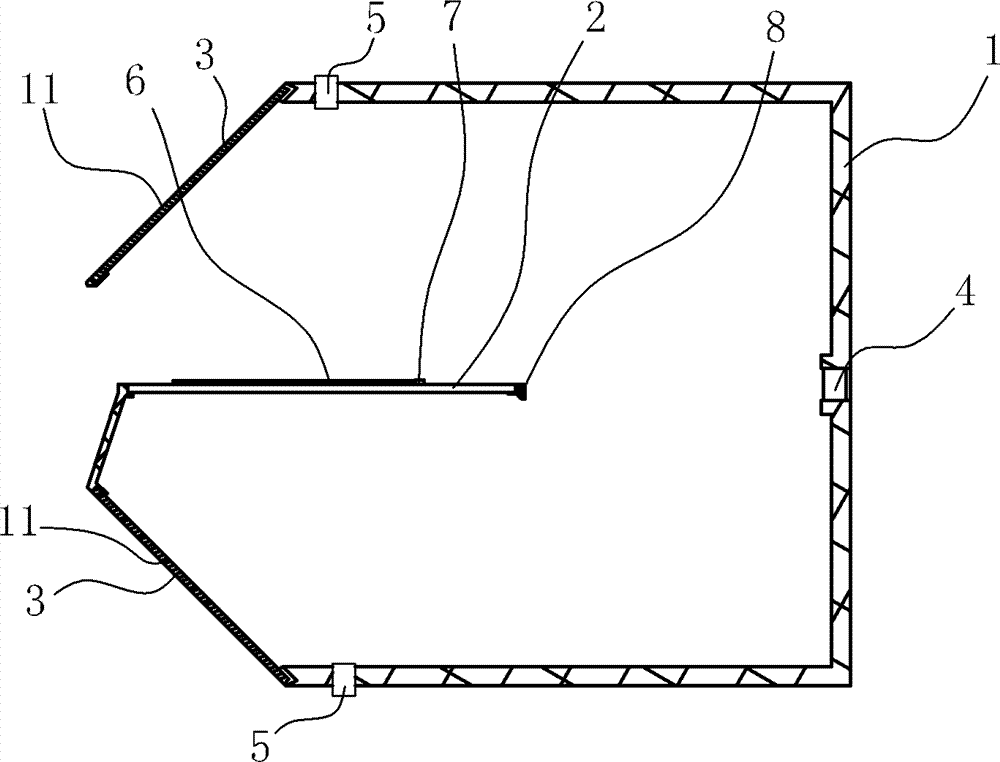

Certificate shooting method and certificate shooting instrument implementing method

InactiveCN102291513BSimple structureReasonable designTelevision system detailsColor television detailsCamera lensCMOS

The invention discloses a certificate shooting method, which comprises the following steps of: manufacturing a box body of which the left side is open; horizontally setting glass at a middle position of the box body and symmetrically setting two plane mirrors on two sides of the glass; setting a shooting module, fixing the shooting module in the middle of a right side in the box body, and enabling the glass to be flush with the shooting module; respectively setting a light source at positions over against the upper surface and the lower surface of the glass at the top and the bottom of the box body; putting a certificate on the glass in the box body from the left side of the box body to be positioned; converging light onto the shooting module, converging the light reflected through the two plane mirrors onto a CMOS (complementary metal oxide semiconductor) image sensor by using a lens, so as to convert a light signal into an image electric signal; and setting driving software carrying out image processing on the image electric signal, mounting the driving software in a computer, connecting the shooting module with the computer, and automatically processing the image electric signal through the driving software, so as to obtain a front-back electronic image of the certificate in a full size. The invention further discloses a certificate shooting instrument.

Owner:GUANGDONG LITE ARRAY

Detection device and method for appearance and assembly of electric paper book based on machine vision

ActiveCN102353683BEasy to useEasy to operateOptically investigating flaws/contaminationMachine visionEconomic benefits

The invention discloses a detection device for apparent defects and an assembly of an electric paper book. Three-section type online detection is adopted in the detection process of the device and back side detection of a product is carried out in a gap of the sections; and detection for the requirements on pollution, scratches, missing parts, assembly errors and the like is carried out by detection software based on a pattern recognition algorithm. According to the electric paper book detection device defined by the invention, the position of the electric paper book is transmitted to a camera through a sensor to trigger and collect images; and then background analysis is carried out according to the collected images. The design of the device guarantees an automatic flow of the detection process and the detection state can be monitored; and then products can be processed by a qualified / unqualified classification according to a detection result. By using the electric paper book detection device disclosed by the invention, objective and accurate detection can be obtained. In addition, the operation of the device is convenient and easy to understand and the defects of the electric paper book can be accurately detected without professional skills, so that careless mistakes caused by the judgment of artificial subjective factors can be effectively prevented and the detection deviceis good for improving the work efficiency of staff and the economic benefits of enterprises.

Owner:苏州优纳科技有限公司

Method for measuring physicochemical property of substrate in vegetable intensive seedling cultivation

InactiveCN110361513AAccurate and suitable for measurement conditionsSampling is reasonablePreparing sample for investigationTesting waterMatrix solutionFiltration

The invention relates to a method for measuring the physicochemical property of a substrate in vegetable intensive seedling cultivation. The method comprises the steps of: before the measurement of the physicochemical property of a vegetable plug seedling substrate, permeating the substrate with normal irrigation water to keep the substrate in a saturated state for more than 1 hour; taking the water-permeated substrate and the seedlings out of a plug, wherein the volume of the taken-out substrate is required to be over 100 ml, that is, a 72-hole plug requires the substrate of 5 holes; separating the seedlings from the substrate, wrapping the substrate in a filter towel, squeezing the water contained in the substrate, pouring the extracted solution directly into a beaker; filtering the extracted solution with filter paper, and directly measuring the filtered solution with a pH meter and an EC meter at room temperature to obtain the physicochemical property index around the substrate rhizosphere. The method is designed to be reasonable, practical and easy to operate based on the preparation method of the substrate solution, the extraction method of the substrate solution, and the filtration method of the substrate solution, so that the data of the physicochemical property of the substrate is accurate and the method is convenient and reasonable.

Owner:山东省寿光市三木种苗有限公司 +1

High-sensitivity MEMS heart sound and electrocardio integrated detection sensor based on beat-type bionic cilia

The invention relates to a high-sensitivity MEMS heart sound and electrocardio integrated detection sensor based on beat-type bionic cilia, which mainly comprises a probe shell, an MEMS acoustic sensor microstructure, a heart sound and electrocardio integrated circuit and a signal acquisition card; the MEMS acoustic sensor microstructure is provided with the beat-type bionic cilia for detecting heart sound signals; an electrocardio electrode on the probe shell is used for detecting electrocardio signals; the electrocardio electrode and the probe shell transmit the detected signals to the heart sound and electrocardio integrated circuit for processing; and then, the processed signals are transmitted to the signal acquisition card. The invention has the advantages of being scientific in design, reasonable in structure, easy and convenient to operate, convenient to carry, sensitive in detection, low in cost, capable of being machined in batches, capable of realizing synchronous heart sound and electrocardio detection and the like; and compared with a traditional sensor probe, heart sound and electrocardio signal detection is more accurate, rapid and convenient.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com