A kind of production equipment and production process of fungus bag

A kind of production equipment and agaric fungus technology, applied in the field of agaric fungus bag production equipment and production technology, can solve the problems of heavy labor, uneven mixing, material transfer pollution, etc., to avoid energy consumption, facilitate material discharge operation, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further illustrated by the following examples.

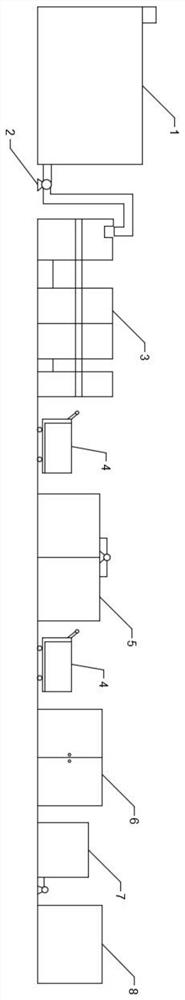

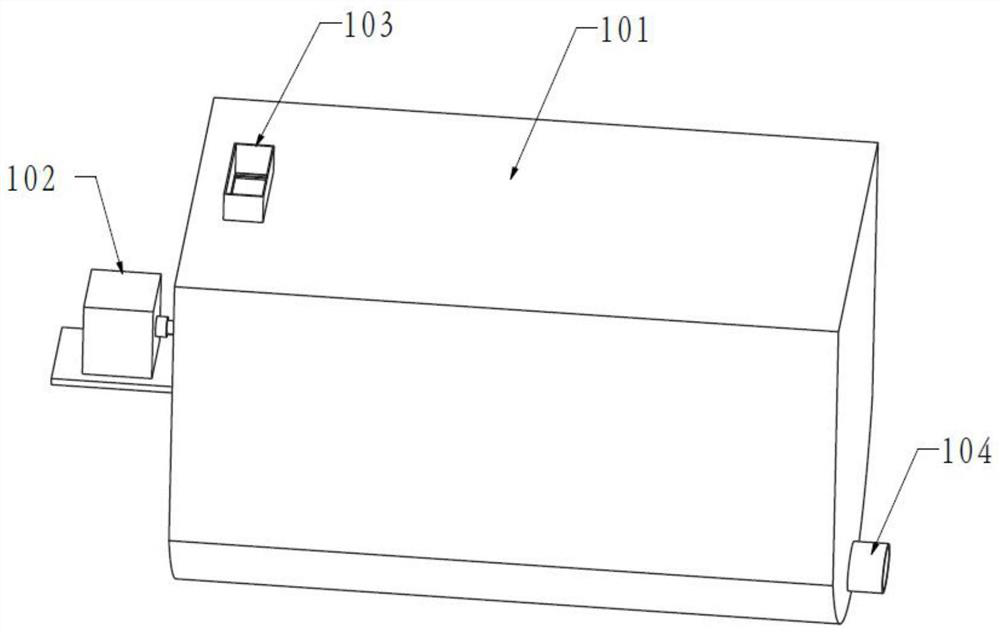

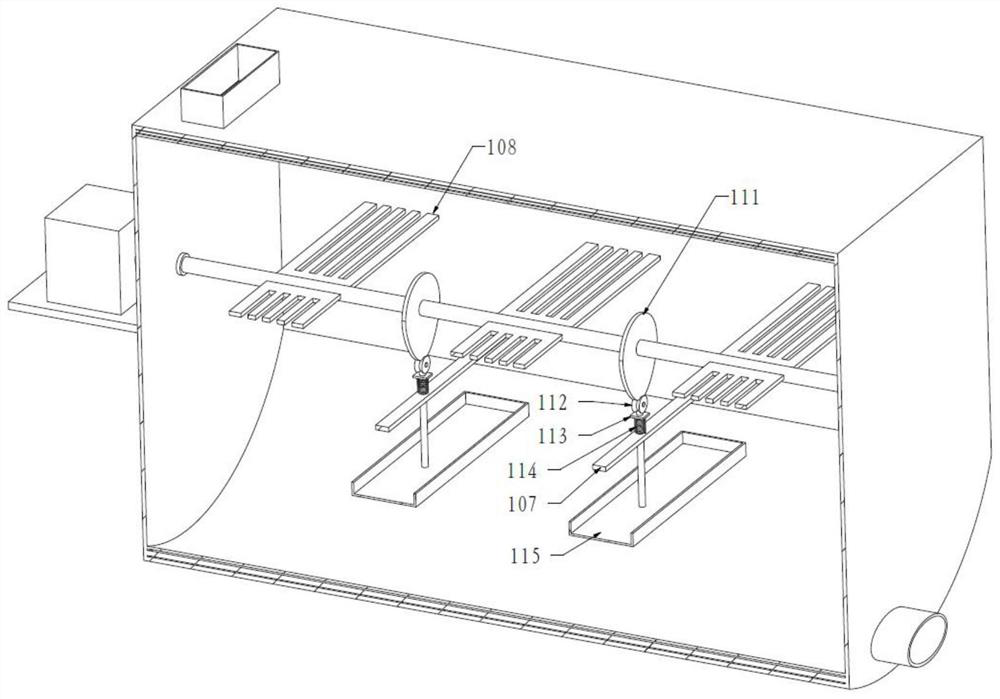

[0040] A kind of Agaric fungus bag production equipment, comprises culture raw material mixer 1, automatic packing machine 3, bacteria bag cooling chamber 6, inoculation machine 7 and culture room 8, described culture raw material mixer 1 comprises main stirring mechanism and auxiliary stirring mechanism, described The main stirring mechanism is arranged above the auxiliary stirring mechanism. The main stirring mechanism includes a main shaft 109 and stirring blades 108 arranged on the main shaft 109 at a distance. Auxiliary mixing mechanism; the cultivation raw material mixer 1 is connected with the rotating material conveyor 2 to transport the uniformly mixed and stirred raw materials to the automatic packaging machine 3 for operations such as loading, bagging, side inserting, nest opening, etc., and the bacteria will be packaged in the In the transport frame, it is then transported into the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com