On-site original grading rockfill material mechanical parameter speculation method

A technology of mechanical parameters and rockfill materials, applied in the field of on-site mechanical parameter estimation of original graded rockfill materials, can solve problems such as difficulty in obtaining mechanical parameters of original graded rockfill materials, achieve practicality, theoretical and technical feasibility, and improve prediction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

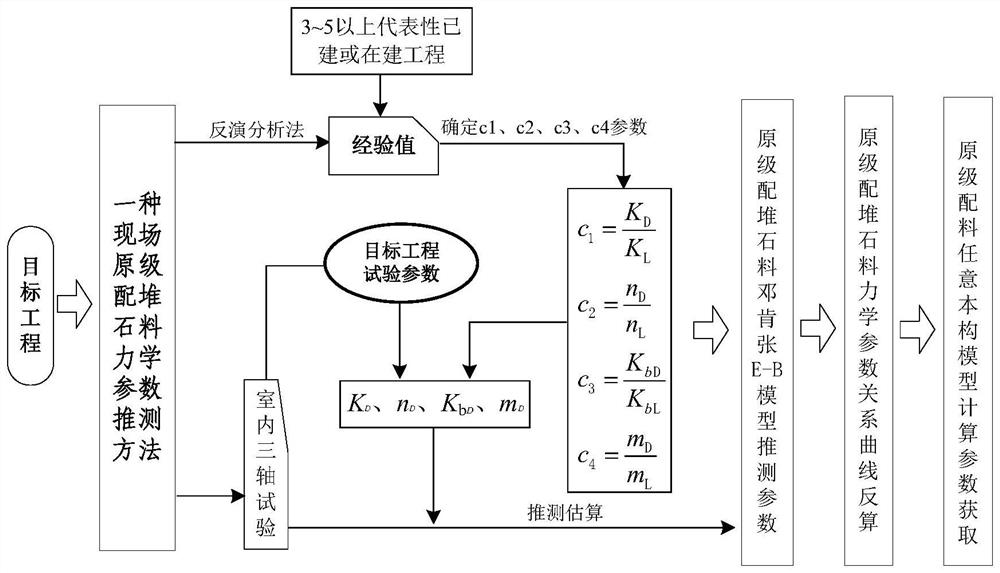

[0024] A method for estimating mechanical parameters of original graded rockfill materials on site is provided, including the following steps:

[0025] Obtain the scale factor: Based on the inversion analysis of the prototype observation data of the built or under construction project, through the analogy method of engineering experience, the scaling factor of the scaling effect that affects the mechanical parameters is obtained;

[0026] Estimated impact: Based on the Duncan-Zhang E-B model, approximate the impact of scaling effects on calculation parameters;

[0027] Scale calculation: According to the estimated scale factor of the scale effect and the test parameters, the parameter back calculation is carried out to obtain the mechanical parameters of the original graded rockfill material.

Embodiment 2

[0029] Based on embodiment 1, and in the step of estimating the impact, the calculation parameters are selected K, n, K b , m is representative, among them, K is the tangent elastic modulus number, n is the tangent elastic modulus index, K b is the tangent bulk modulus number, m is the tangent bulk modulus index.

Embodiment 3

[0031] Based on Example 1, and the scaling factor of the scale effect is the relationship between the primary ingredient parameters at the target project site and the indoor triaxial test parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com