Machining method for guaranteeing position accuracy of cartridge receiver hole system

A processing method and technology of position degree, which can be used in positioning devices, metal processing equipment, metal processing mechanical parts, etc., and can solve the problems of out of tolerance, inability to monitor the processing process, and no proofreading process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Process a certain type of engine main case, the height is 450mm, the length is 1000mm, and the width is 800mm. A hole 1 is processed on it, and the hole 1 has a requirement of a positional degree of 0.1 mm for the datums D, E, and F.

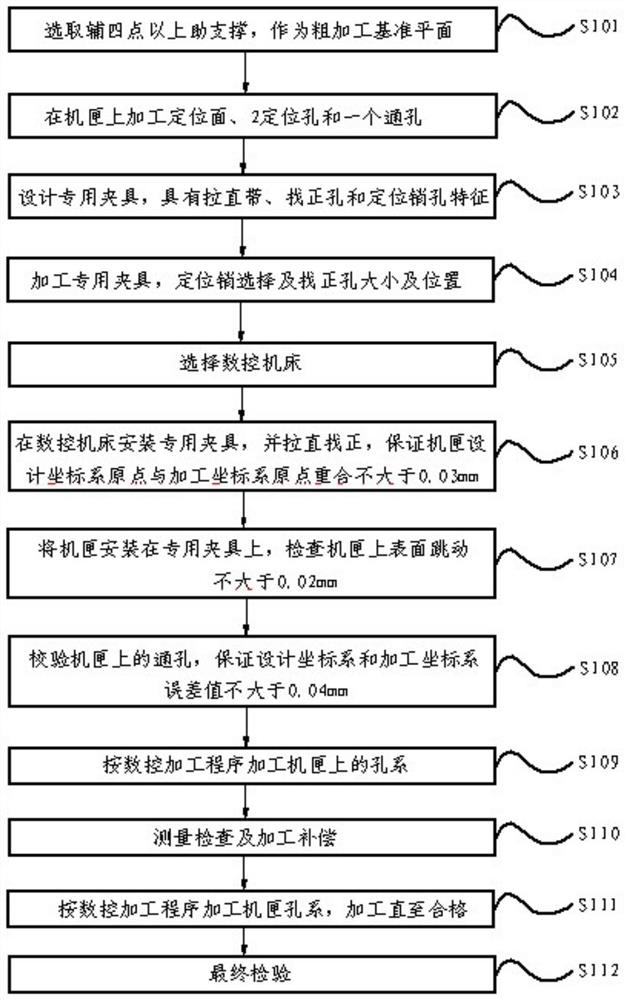

[0054] Such as figure 1 As shown, the processing steps are as follows:

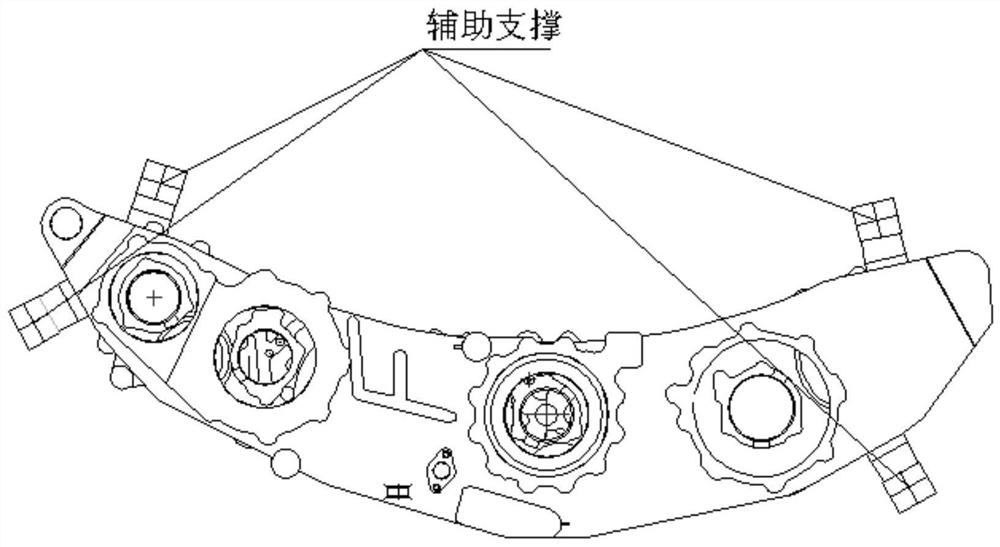

[0055] 1. According to the size of the receiver, select four auxiliary supports, such as figure 2 As shown in , the positioning block is used as the reference plane for rough machining of the casing;

[0056] 2. Process the positioning reference on the casing, the flatness of the positioning plane of the reference is 0.02mm, process two positioning holes on the positioning surface, and the position of one hole relative to the other hole is 0.015mm, which is consistent with the positioning surface of the casing The verticality is φ0.03mm. At the same time, a through hole is processed on the casing. The position of the through hole and the two positioning holes is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com