Machining method for sawtooth-shaped threads of hydraulic nut of large ship shafting

A technology of hydraulic nuts and processing methods, which is applied in the direction of metal processing equipment, large fixed members, metal processing machinery parts, etc., and can solve problems such as tool vibration, cutting resistance affecting the accuracy of machine tool ball screw pairs, and difficult to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

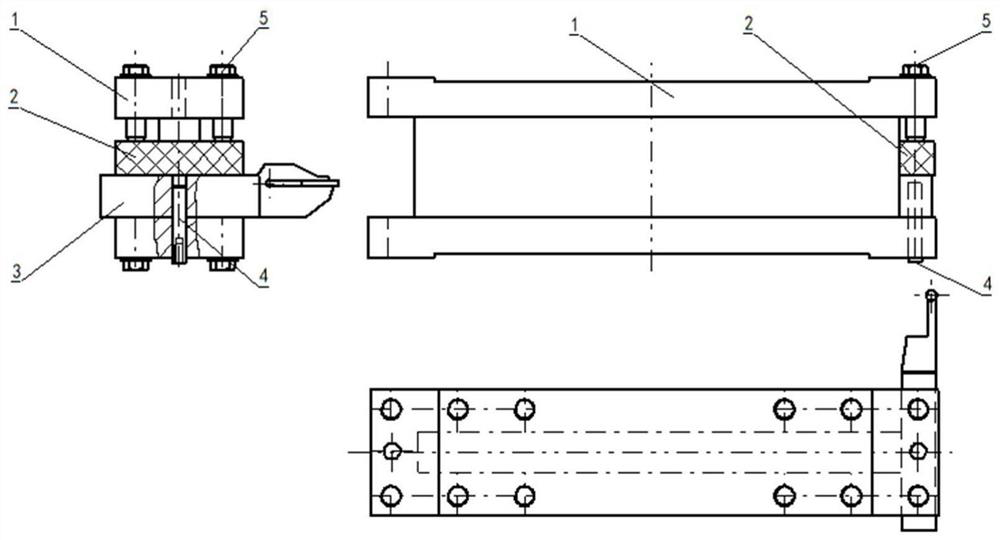

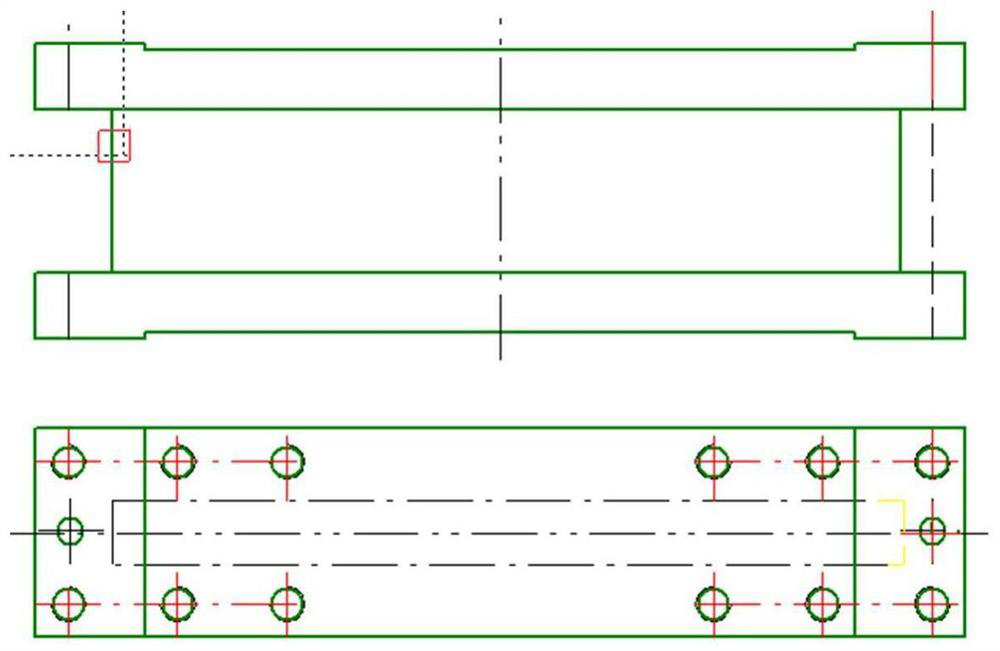

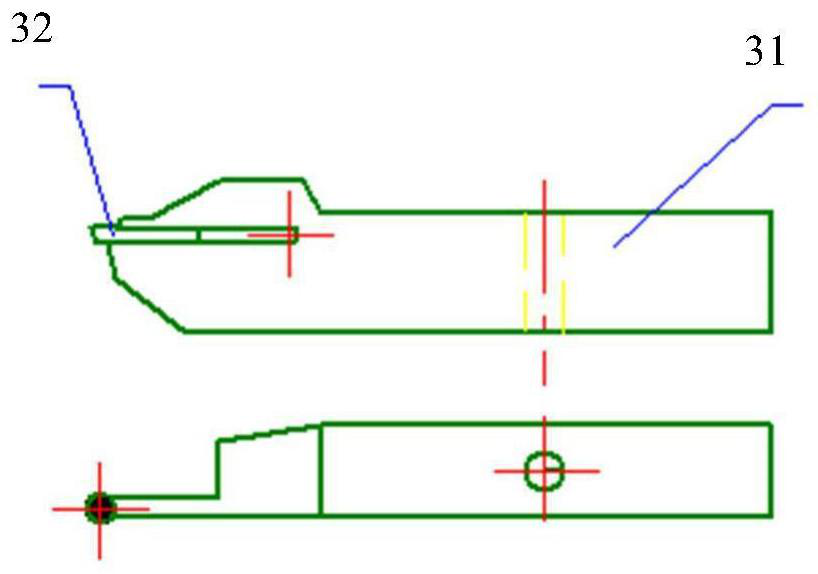

[0021] The processing method of the large ship shafting hydraulic nut serrated thread of the present invention is further described below in conjunction with the accompanying drawings, and the specific steps are as follows:

[0022] a. It is suitable for 0° / 45° sawtooth thread turning, with a pitch of P=12 and above; it is processed by a carbide machine-clamped arc turning tool, and the tooth shape is divided into multi-layer cutting, and the turning trajectory is straight line, arc insertion Complementary combination of turning methods. Select the nose arc radius. The range of the tool nose radius is best controlled between R1.5~R2.5mm. If it is larger than R2.5, it will affect the finishing due to the large allowance. If it is smaller than R1.5, the rigidity of the tool body will be deteriorated. In actual processing, the appropriate tool nose radius should be selected according to the material and rigidity of the workpiece, and can be determined by trial cutting if necessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com