Brushless stator terminal assembling machine

A stator terminal and assembly machine technology, applied in the manufacture of stator/rotor bodies, metal processing, metal processing equipment, etc., can solve the problems of time-consuming, labor-intensive, manpower-dependent, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

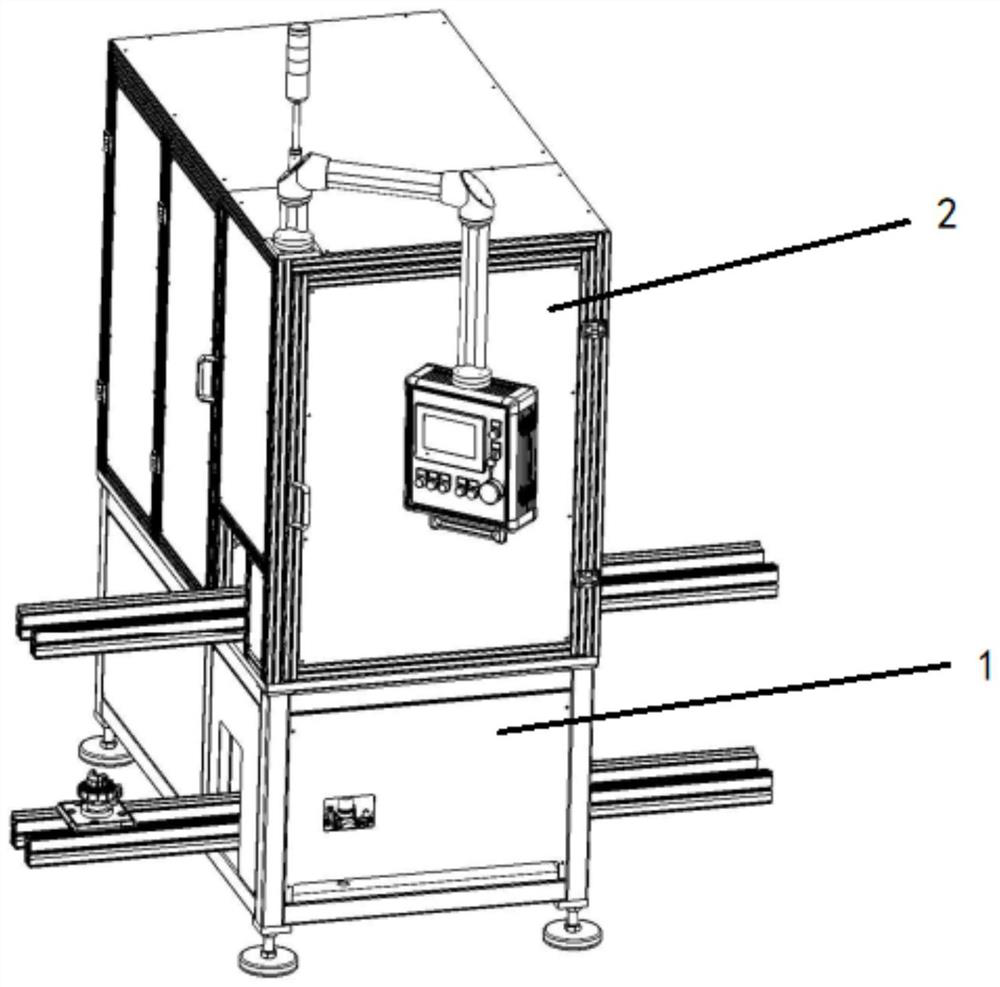

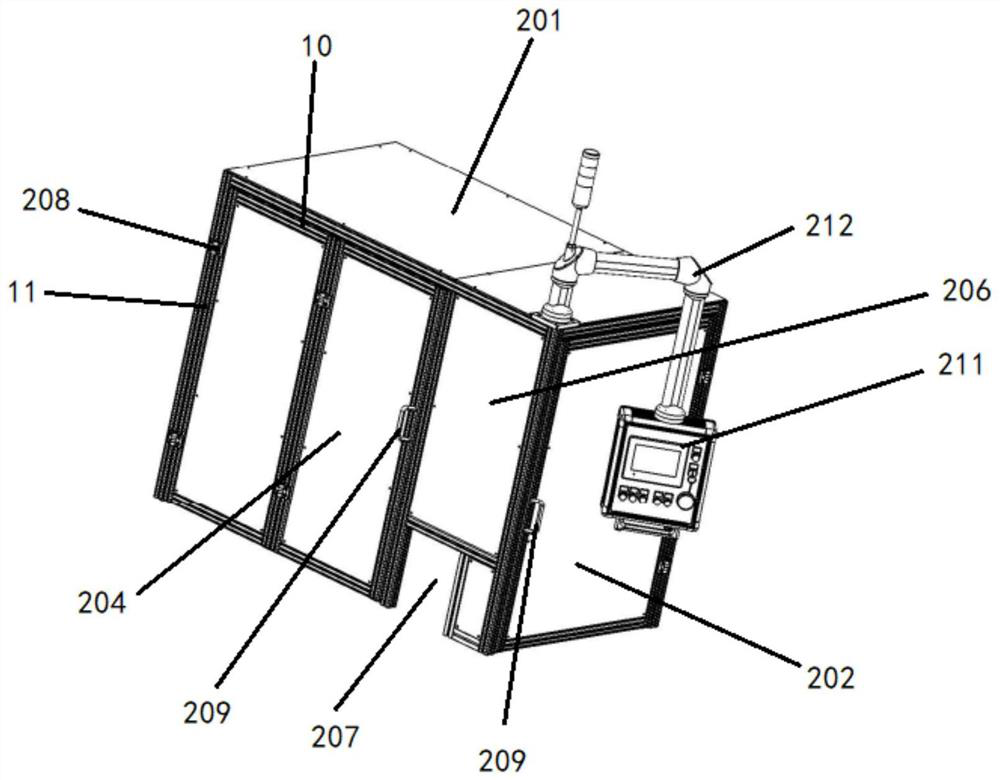

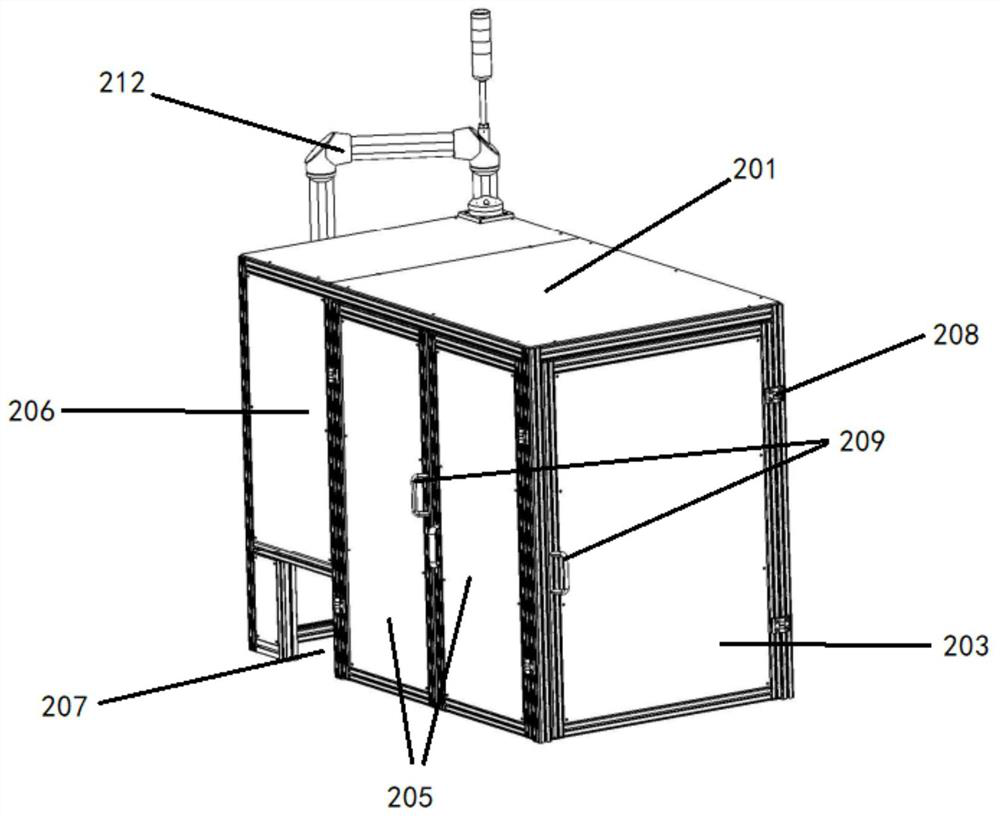

[0061] Such as figure 1 As shown, the present invention discloses a brushless stator terminal assembly machine, which includes a frame part 1, a protective cover part 2, a straightening tool traversing part 3, a traversing conveying and pressing part 4, and a vibrating plate feeding part 5; The above-mentioned righting frock traversing part 3, traversing conveying and pressing part 4 and vibrating plate feeding part 5 are arranged on the frame part 1, and the protective cover will set the righting frock traversing part 3, traversing conveying and pressing part The part 4 and the vibrating plate feeding part 5 are protected inside.

[0062] Such as Figure 5 , 6 As shown, the frame part 1 is composed of a crossbeam 10 and a vertical beam 11 to form a hollowed-out cuboid, and the hollowed-out rectangle can place various electrical components inside to the greatest extent; the hollowed-out cuboid includes a table panel 101 and a valve island box 102 , the electrical box 103, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com