Finishing machining air pressure abrasive pool device for complex curved surface workpieces

A technology for finishing and complex curved surfaces, which is applied in metal processing equipment, surface polishing machine tools, machine tools suitable for grinding workpiece edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

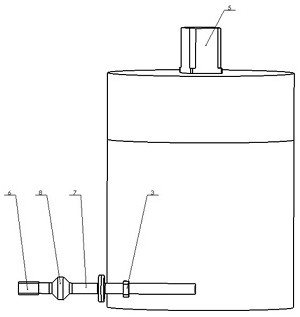

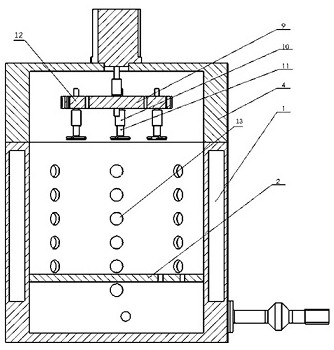

[0020] Pneumatic abrasive pool for finishing complex curved surfaces, which is characterized in that the air is compressed and filtered by the air compression device [6], and then sent to the heating device [3] to heat up the gas, and the gas transmission rate is adjusted by the air pressure control device [3] , which then sends gas to the bottom and side vents. The air hole blows up the specific abrasive in the abrasive pool to form a fluid-like abrasive flow; the rotary device includes a workpiece clamping device [11], a bracket [10], and a stepping motor [5], in which the workpiece clamping device will drive the workpiece to rotate Then fully contact with the abrasive flow to complete the task of finishing the complex curved surface.

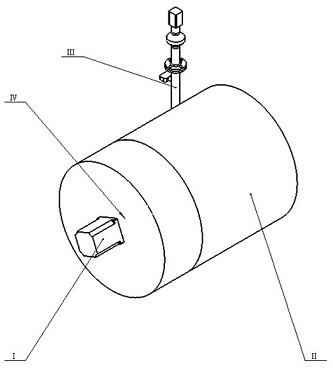

[0021] The gas injection device [Ⅲ] is composed of a vent pipe [3], an air hole [2], a filter screen and a spray nozzle; The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com