Steel plate double groove edge milling machine milling head driving and vertical fine adjustment mechanism

A technology of double-sided groove and fine-tuning mechanism, which is applied to the driving device, milling machine equipment, details of milling machine equipment, etc., can solve the problems of high labor intensity, low work efficiency, poor adjustment accuracy, etc. The effect of reducing labor intensity and low noise of groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

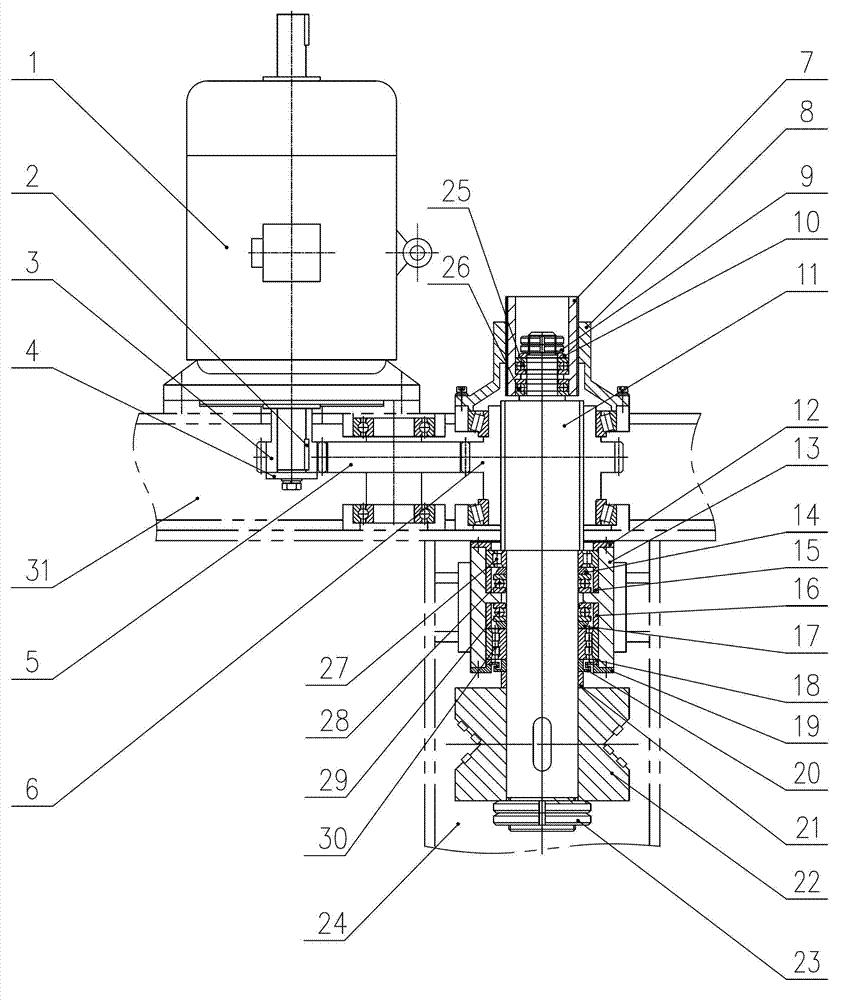

[0012] Such as figure 1 As shown, the present invention mainly consists of a reducer 1, a flat key 2, a driving gear 3, a gear end cover 4, a transition gear 5, a driven gear 6, an adjusting screw nut 7, an adjusting end cover 8, a small round nut 9, a first Spacer 10, milling cutter shaft 11, upper end cover 12, sliding sleeve 13, second spacer 14, first spacer 15, second spacer 16, third spacer 17, inner spacer 20, outer spacer 18. Lower end cover 19, third spacer ring 21, milling cutter head 22, large round nut 23, first ball thrust bearing 25, second ball thrust bearing 26 cylindrical roller bearing 27, third ball thrust bearing 28, The fourth ball thrust bearing 29 and the double-row cylindrical roller bearing 30 are composed of components.

[0013] Such as figure 1 As shown, the driving gear 3 is installed on the output shaft of the reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com