Production equipment and production technology of auricularia auricula fungus bags

A kind of production equipment and agaric fungus technology, applied in the field of agaric fungus package production equipment and production technology, can solve the problems of insufficient fast and timely material transfer in the production line, steam consumption, vacuum pump energy consumption, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further illustrated by the following examples.

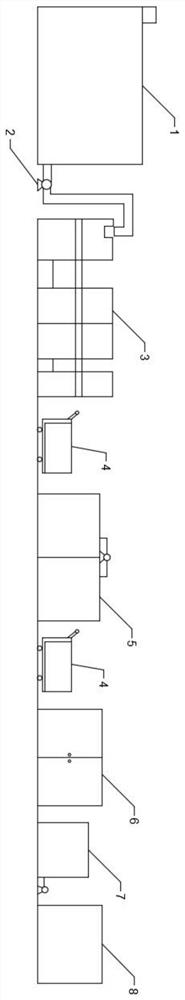

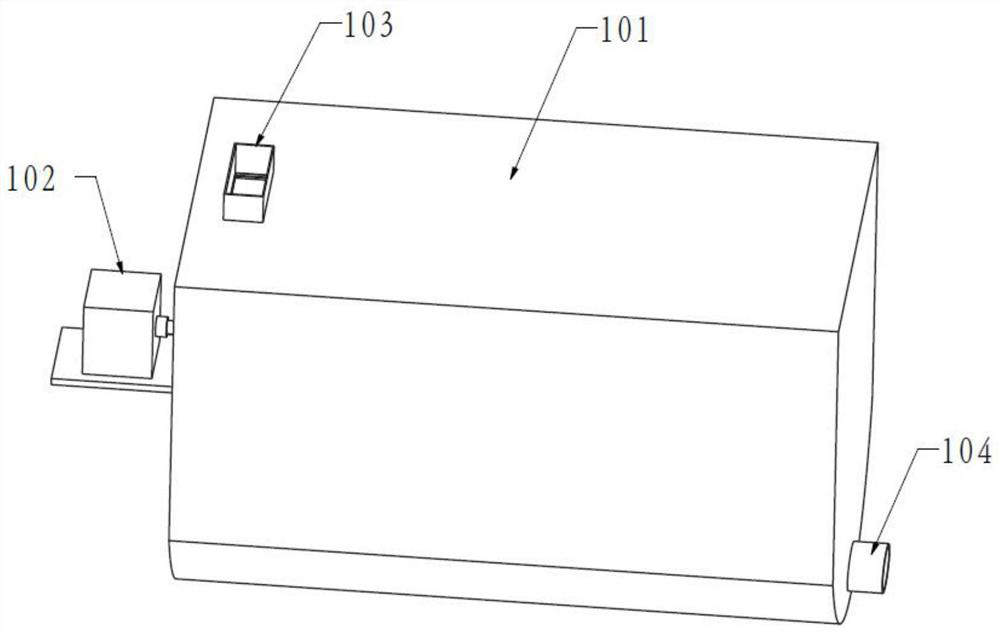

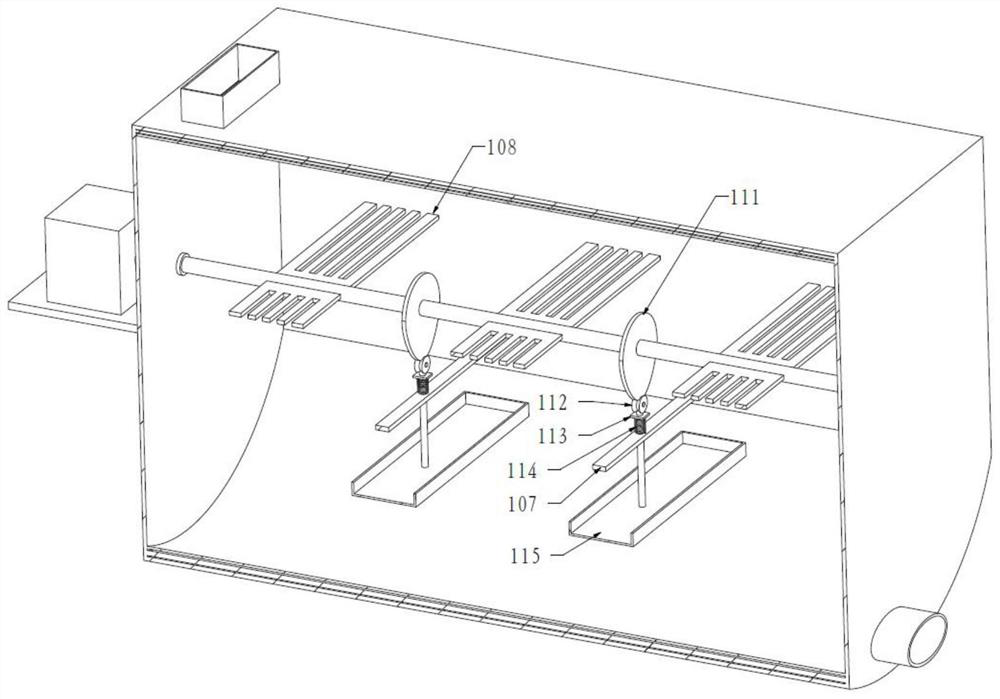

[0040] A fungus bag production equipment, comprising a culture material mixer 1, an automatic bag packing machine 3, a bacteria bag cooling chamber 6, an inoculation machine 7 and a culture chamber 8, and the culture material mixer 1 includes a main stirring mechanism and an auxiliary stirring mechanism. The main stirring mechanism is arranged above the auxiliary stirring mechanism, and the main stirring mechanism includes a main shaft 109 and a stirring blade 108 arranged on the main shaft 109 at a distance. Auxiliary stirring mechanism; the culture raw material mixer 1 is followed by a rotary material conveyor 2 to transport the evenly mixed and stirred raw materials to an automatic packaging machine 3 for operations such as charging, bagging, inserting, and nesting, and packing the bacteria into In the transport frame, it is then transported into the pulsating vacuum sterilizer 5 by the rapid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com